215916 400 Revision A

4. Remove check plug (B). The lubricant should be visible

through the port. Some lubricant may leak from the port. If

lubricant needs to be added, refer to 5.10.6 Adding Wheel

Drive Lubricant – 12 Bolt (Optional), page 400.

NOTE:

The type of lubricant used after the first lubricant change is

different from the factory-supplied lubricant.

5. Reinstall check plug (B) and torque it to 7.5 Nm (6 lbf·ft).

6. Reinstall fill/drain plug (A) and torque it to 24 Nm

(18 lbf·ft).

5.10.5 Adding Wheel Drive Lubricant – 10 Bolt

NOTE:

Do NOT mix lubricants of different brands or characteristics.

NOTE:

For lubricant specifications, refer to 5.1.4 Lubricants, Fluids, and System Capacities, page 328.

DANGER

To prevent bodily injury or death from the unexpected startup of the machine, always stop the engine and remove the

key from the ignition before leaving the operator’s seat for any reason.

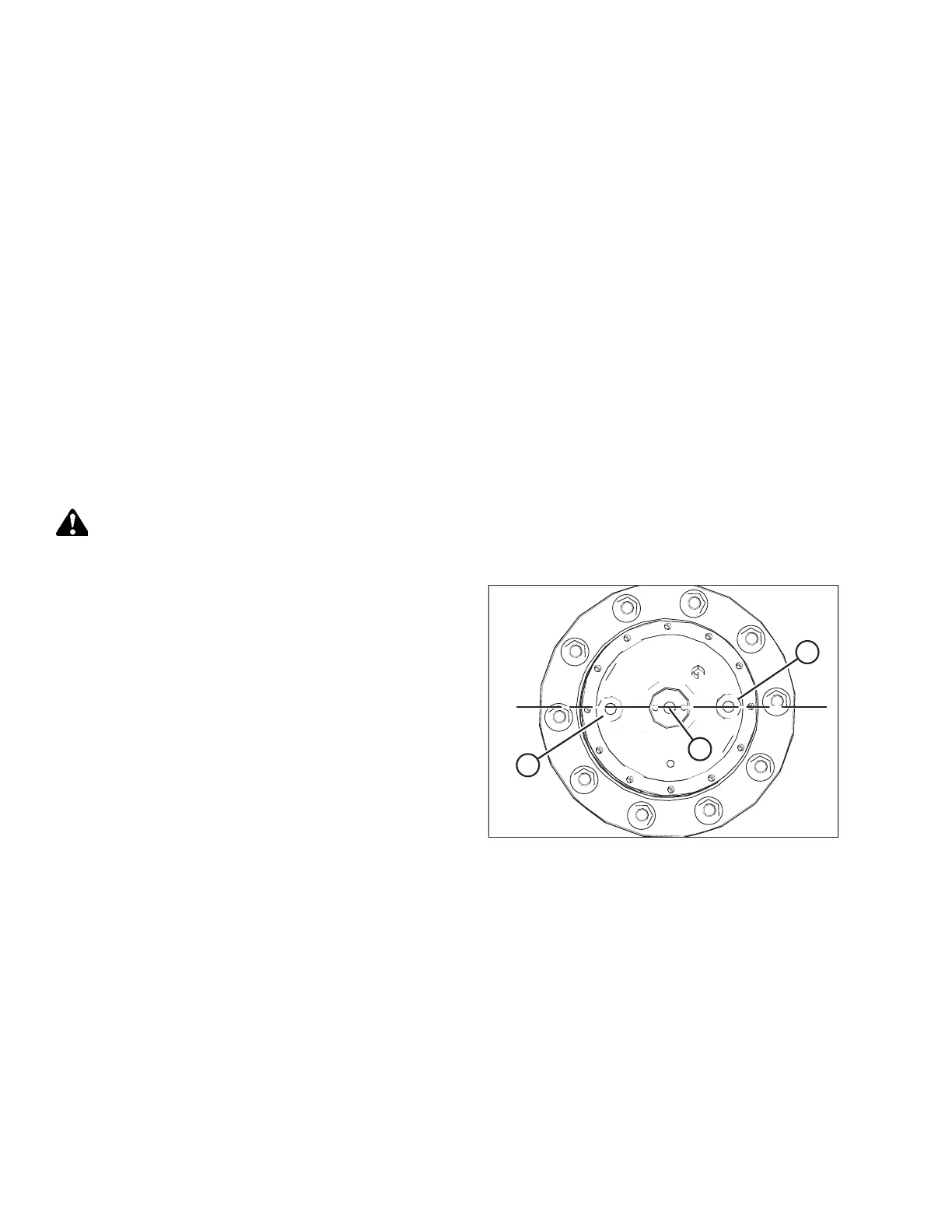

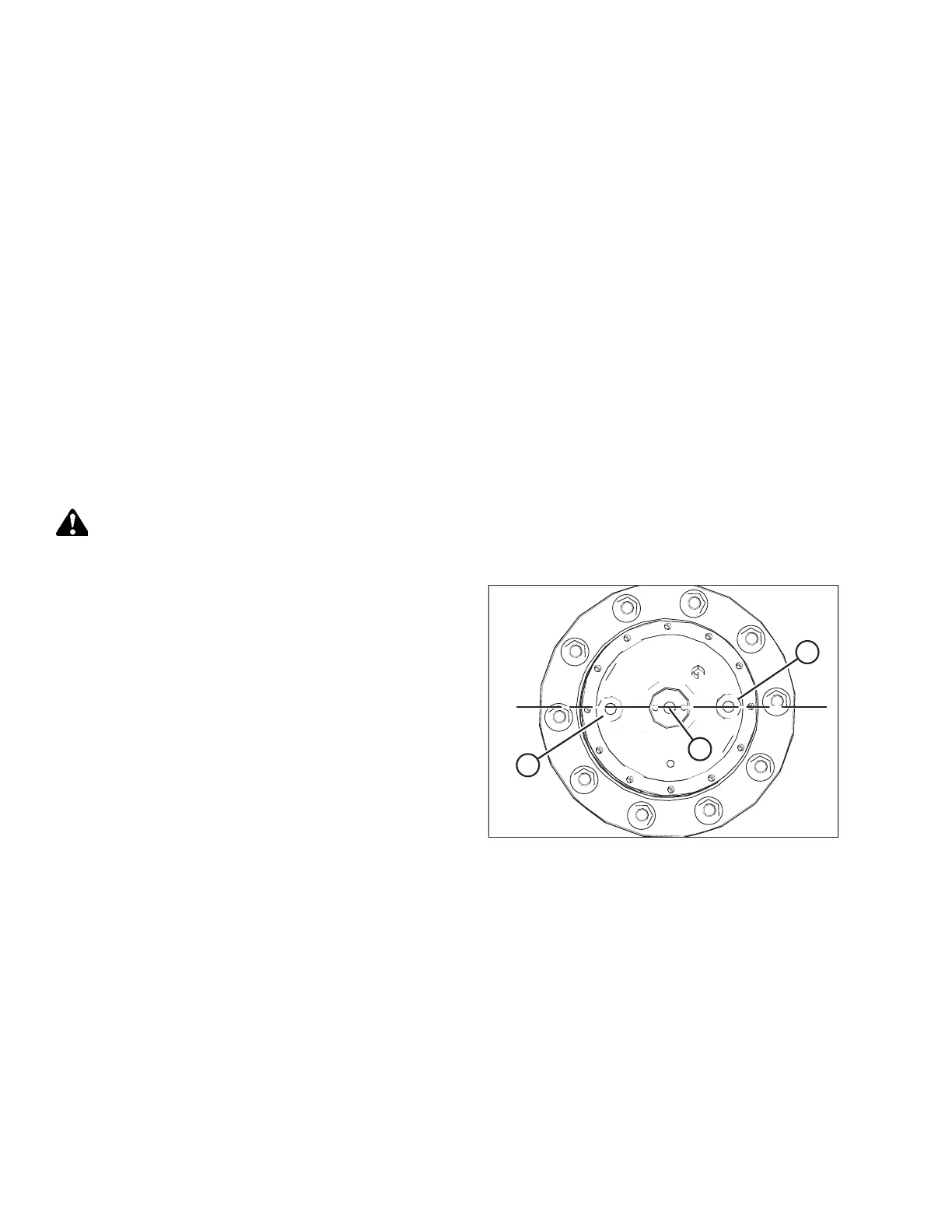

Figure 5.105: Wheel Drive

1. Rotate the wheel drive so plugs (A) and (B) are horizontally

aligned with center (C) of the hub.

2. Shut down the engine, and remove the key from

the ignition.

3. Remove either plug (A) or (B).

NOTE:

PRIOR TO FIRST CHANGE: Use SAE 85W-140, API service,

class GL-5, extreme pressure gear lubricant (non-synthetic).

NOTE:

AFTER FIRST CHANGE: Use SAE 75W-140 or 80W-140, API

service, class GL-5, fully synthetic transmission lubricant

(SAE J2360 preferred).

4. Add lubricant through one of the ports until the lubricant

reaches the bottom of the ports and begins to run out.

5. Reinstall and tighten plug (A) or (B). Torque plug to 24 Nm

(18 lbf·ft).

6. Start up and operate the windrower for a few minutes, then stop and check the oil level. For specifications, refer to

5.1.4 Lubricants, Fluids, and System Capacities, page 328. If necessary, add more oil.

5.10.6 Adding Wheel Drive Lubricant – 12 Bolt (Optional)

NOTE:

Do NOT mix lubricants of different brands or characteristics.

MAINTENANCE AND SERVICING

Loading...

Loading...