K3: Compensations

4.6 Friction compensation (quadrant error compensation)

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

293

Optimization of the compensation parameters

To optimize the compensation parameters, the circularity test must be repeated several

times and the values changed in small increments. It is recommended that the optimization

be performed with different values for radius and path velocity that are typical for the

machining operations performed on the machine.

Each effect of a parameter change should be checked with a subsequent circularity test and

documented.

Mean value generation

If different parameter values result for different radii and path velocities, the best values

should be determined via mean value generation.

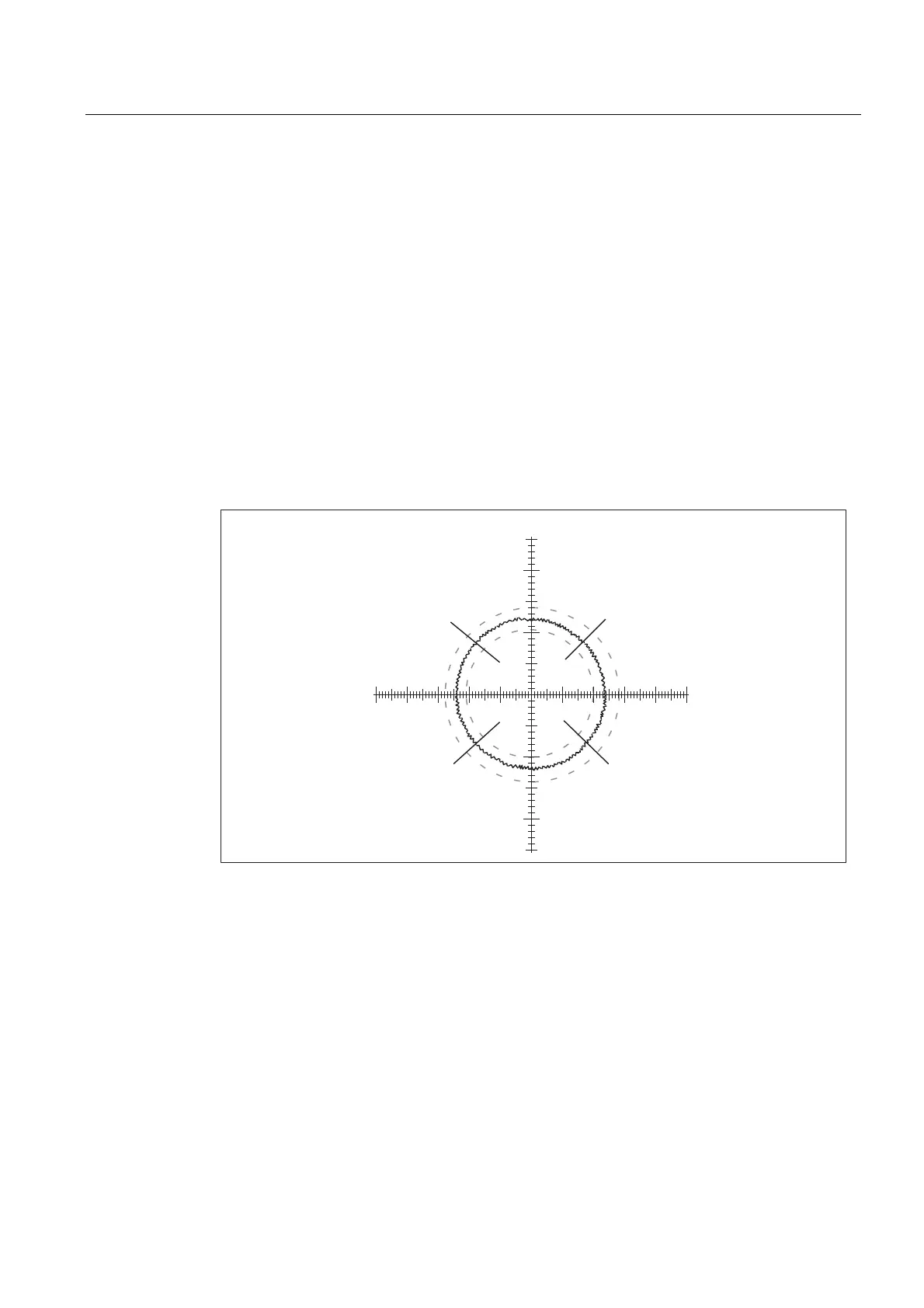

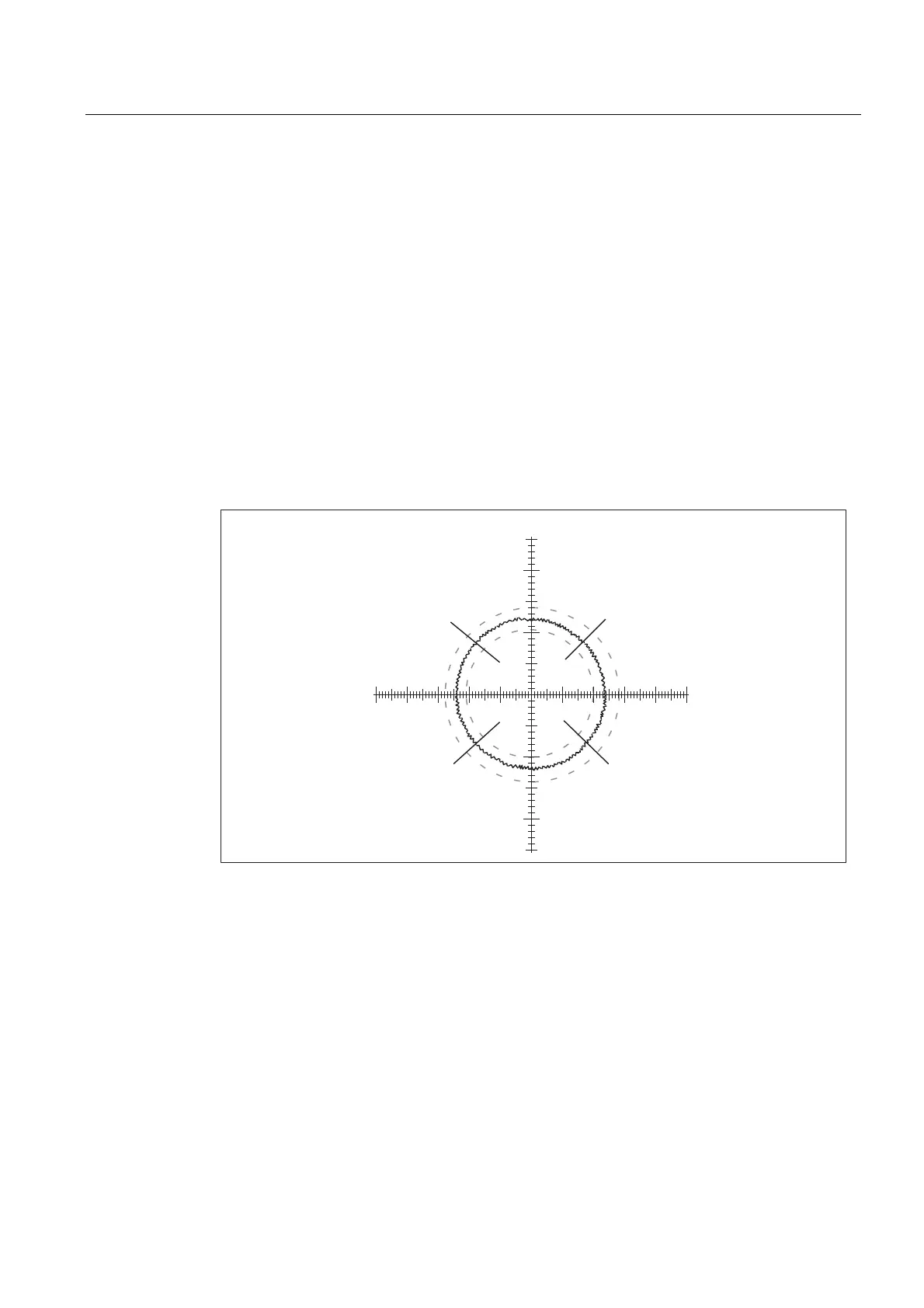

Good friction compensation setting

With a good friction compensation setting, "no" contour violations can be detected at the

quadrant transitions.

,,,

&RXQWHU

&RXQWHU

,

,9

,,

Figure 4-18 Good friction compensation setting

Acceleration-dependent compensation value

If the compensation value proves to be acceleration-dependent, the "friction compensation

and adaptation" described below can be injected in a following step.

Loading...

Loading...