M5: Measurement

7.5 Setting zeros, workpiece measuring and tool measuring

Extended Functions

458 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

The data management frames are read and a new frame set up for the corresponding values

in the variables.

Note

If variables are not set, the active frames are retained.

Values should only be written to those variables whose data management frames are to be

included in the new frame chain. In the case of the basic frames, only all of the frames can

be exchanged, and not just a particular frame. Active changes via $P_NCBFRMASK and

$P_CHBFRMASK are ignored.

Array variable for workpiece and tool measurement

The following array variable of length n is used for further input parameters that are used in

the various measurement types

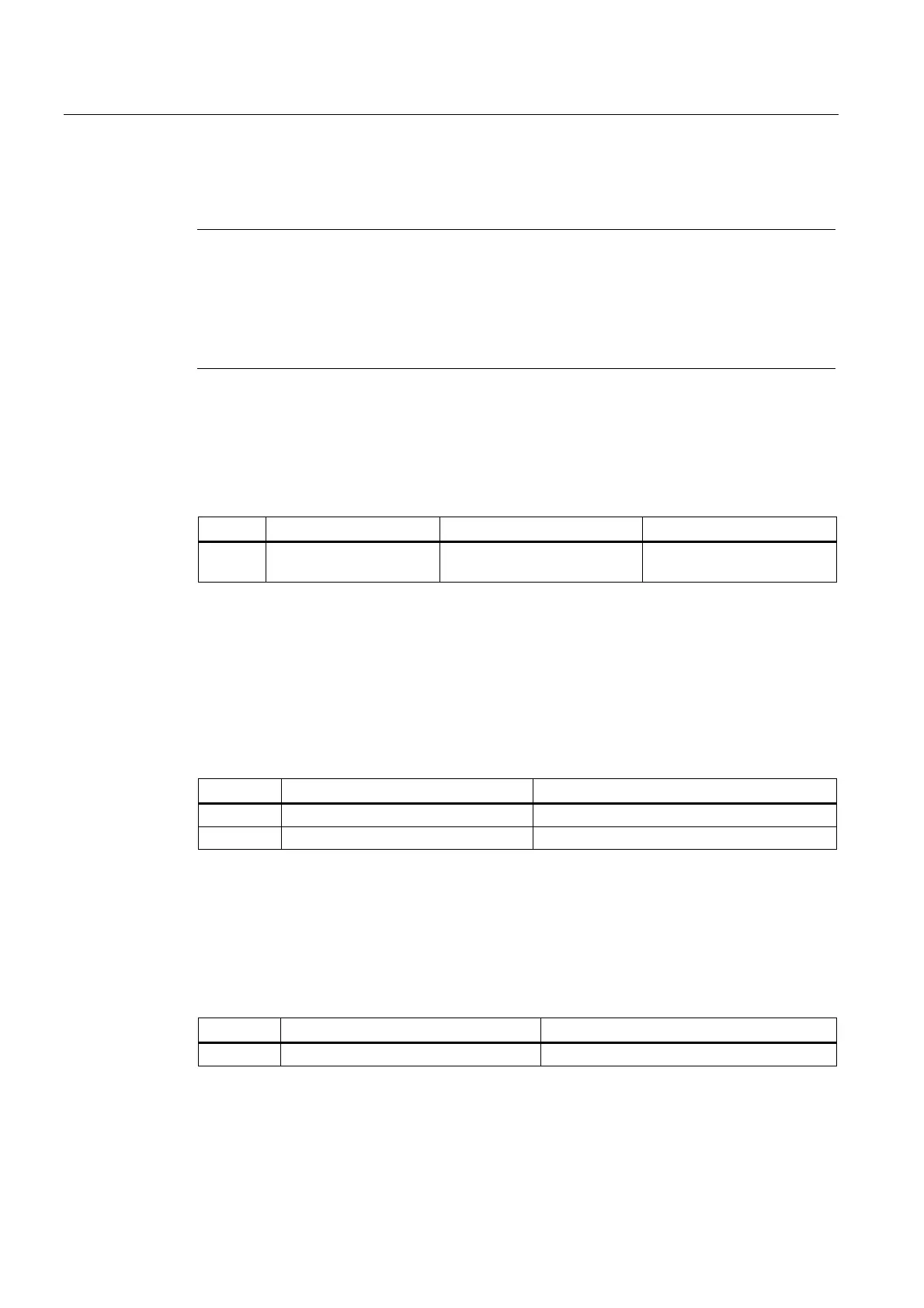

Type System variable Meaning Values

REAL $AC_MEAS_INPUT[n] Measurement input

parameters

n = 0 ... 9

The control action of the measurement input parameters is described with the measuring

methods.

Selection of tool or cutting edge

The tool and edge number of the active tool must correspond to the selected tool. When T0,

D0 is selected, the active tool is calculated. If no tool is active, the tool selected by T, D is

calculated. No tool other than the selected tool may be active.

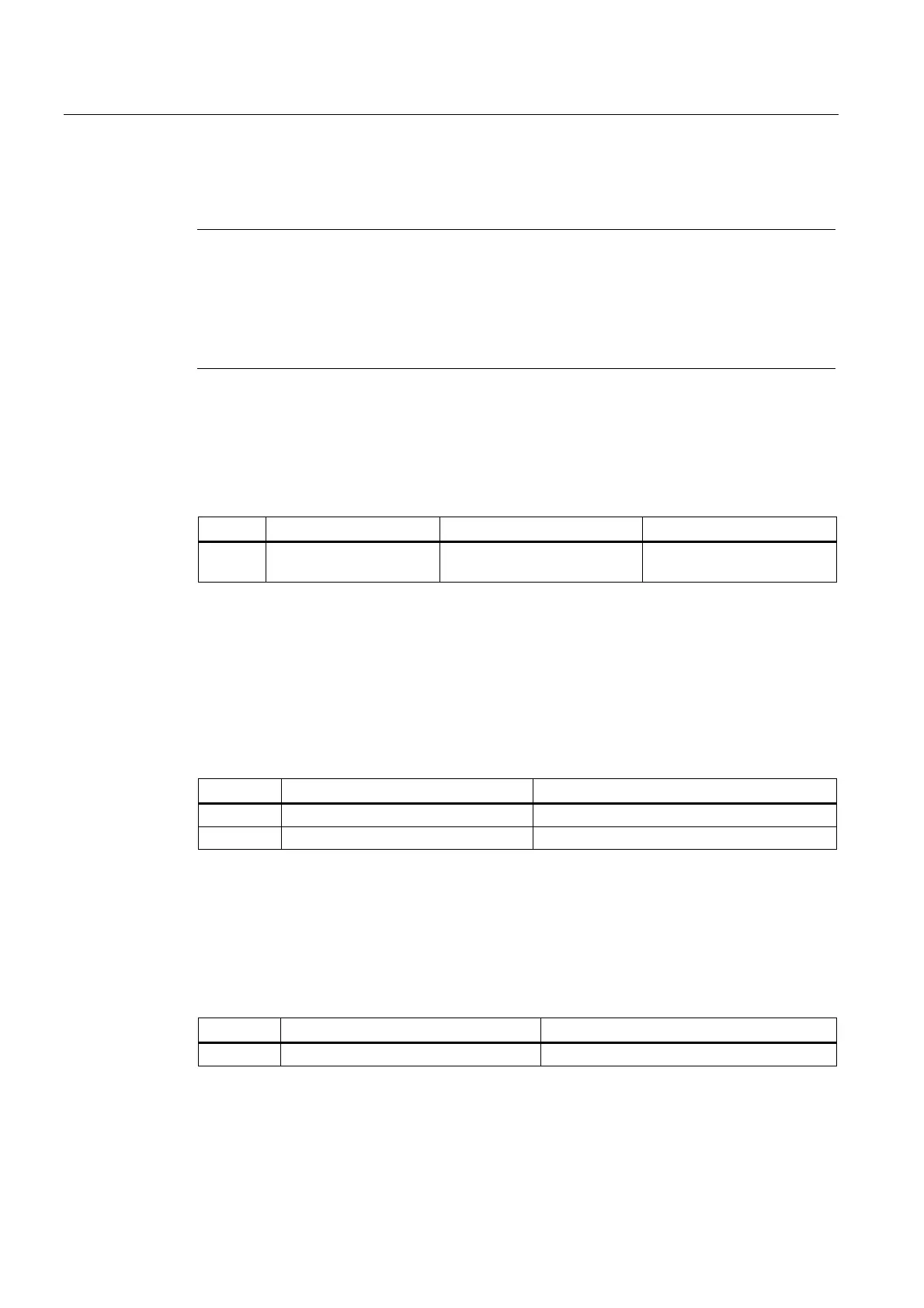

Type System variable Meaning

INT $AC_MEAS_T_NUMBER Selected tool

INT $AC_MEAS_D_NUMBER Selected cutting edge

Measurements with 3D probe

When measuring with the 3D probe, the radius of the tool is already compensated with

reference to the measuring point, and therefore the radius does not have to be included

when calculating the various measurement operations. This property can be defined by

means of the following variable:

Type System variable Meaning

INT $AC_MEAS_TOOL_MASK Tool position

Loading...

Loading...