M5: Measurement

7.5 Setting zeros, workpiece measuring and tool measuring

Extended Functions

478 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

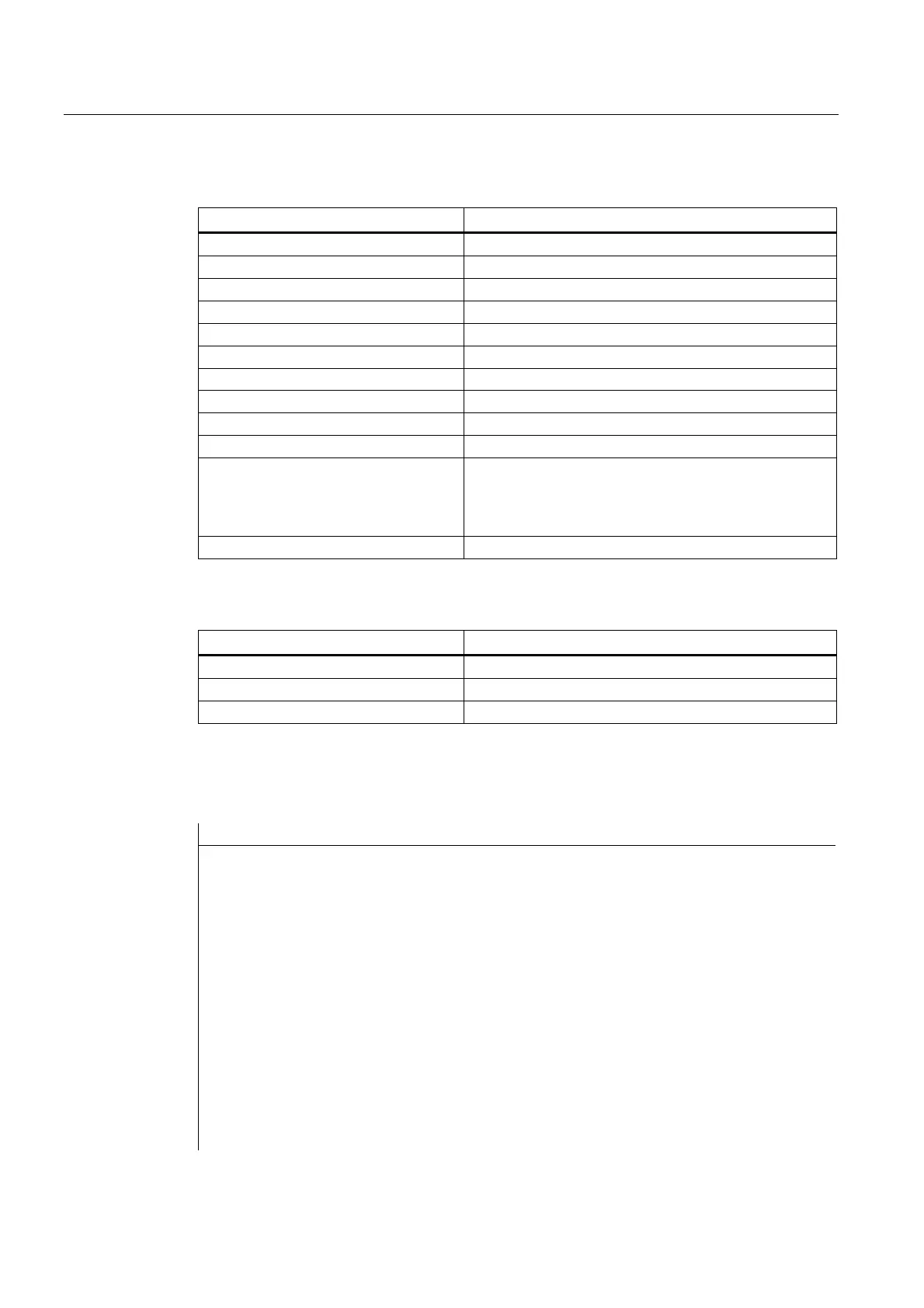

The values of the following variables are evaluated for measurement type 12:

Input variable Meaning

$AC_MEAS_VALID Validity bits for input variables

$AA_MEAS_POINT1[axis] Measuring point 1

$AA_MEAS_POINT2[axis] Measuring point 2

$AA_MEAS_SETPOINT[axis] Setpoint position of groove center *

$AC_MEAS_DIR_APPROACH 0: +x, 1: -x, 2: +y, 3: -y, 4: +z, 5: -z

$AC_MEAS_ACT_PLANE Calculated as active plane unless otherwise specified *

$AC_MEAS_FINE_TRANS 0: Coarse offset, 1: Fine offset *

$AC_MEAS_FRAME_SELECT Calculated as additive frame unless otherwise specified *

$AC_MEAS_T_NUMBER Calculated as active T unless otherwise specified (T0) *

$AC_MEAS_D_NUMBER Calculated as active D unless otherwise specified (D0) *

$AC_MEAS_INPUT[0] Approach direction for 2nd measuring point for a recess

measurement. Must have the same coordinate as the

approach direction of the 1st point. *

0: +x, 1: -x, 2: +y, 3: -y, 4: +z, 5: -z

$AC_MEAS_TYPE 12

* optional

The following output variables are written for measurement type 12:

Output variable Meaning

$AC_MEAS_FRAME Result frame with translation

$AC_MEAS_RESULTS[0] Position of calculated groove center (x0, y0 or z0)

$AC_MEAS_RESULTS[1] Groove width in approach direction

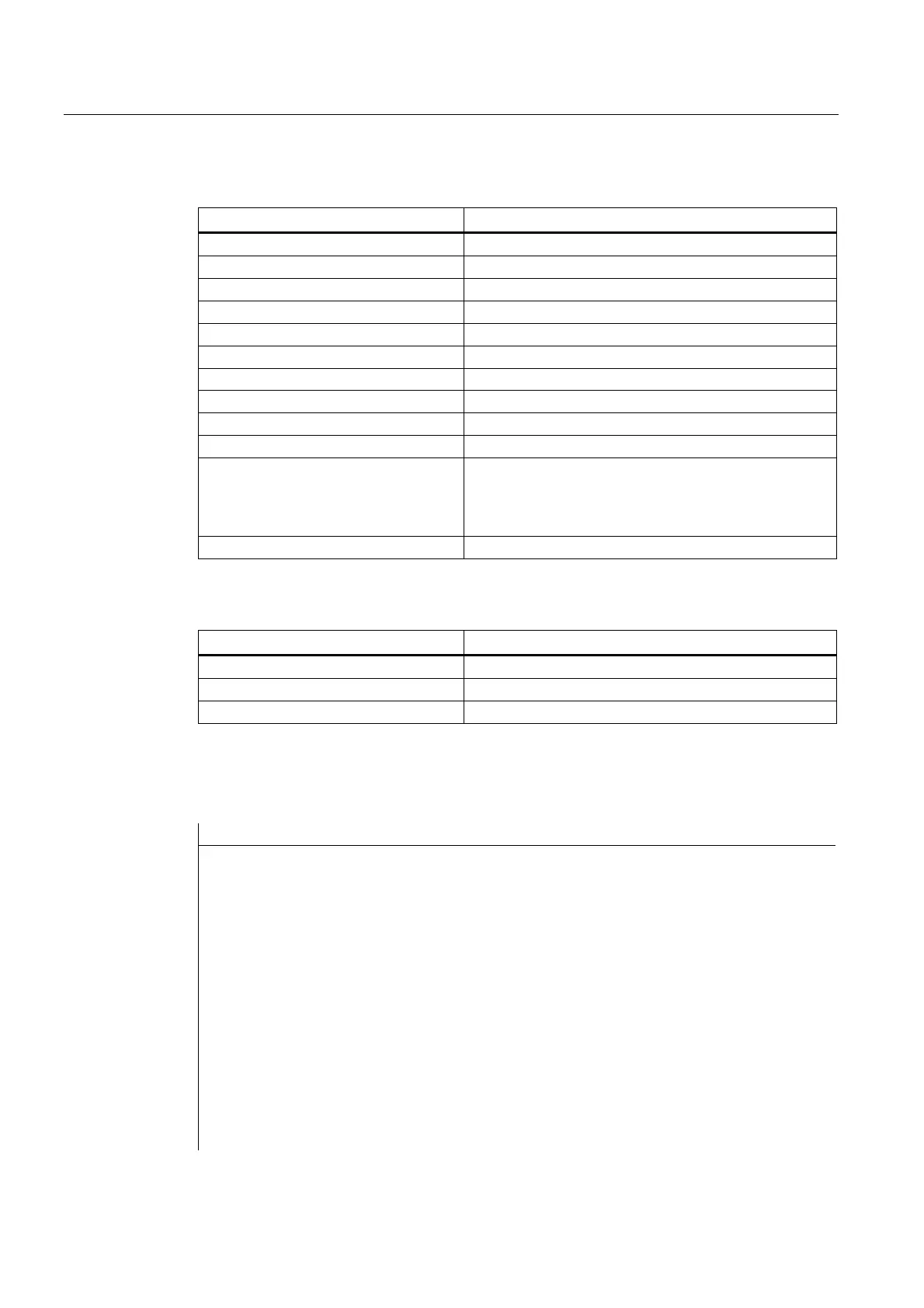

Example

Groove measurement with approach direction in x

Program code Comment

DEF INT RETVAL

DEF FRAME TMP

$TC_DP1[1,1]=120 ; Type

$TC_DP2[1,1]=20 ; 0

$TC_DP3[1,1]=10 ; (z) length compensation vector

$TC_DP4[1,1]=0 ; (y)

$TC_DP5[1,1]=0 ; (x)

$TC_DP6[1,1]=2 ; Radius

T1 D1

g0 x0 y0 z0 f10000

G54

Loading...

Loading...