DISPLAY AND CONTROL ELEMENTS 4

MHL360 E 4.43

4.5.13.6 Grease lubrication system diag-

nostics

The display screens show the operating

states and parameters for the central grease

lubrication system.

Call-up

►

Main control display > Main menu > Diag-

nostics menu > Grease lubricating system

diagnostics

►

Select desired lubricating system

Electronic pump control can be performed in

automatic or manual mode. The correspond-

ing display screens are shown.

Setup of automatic mode

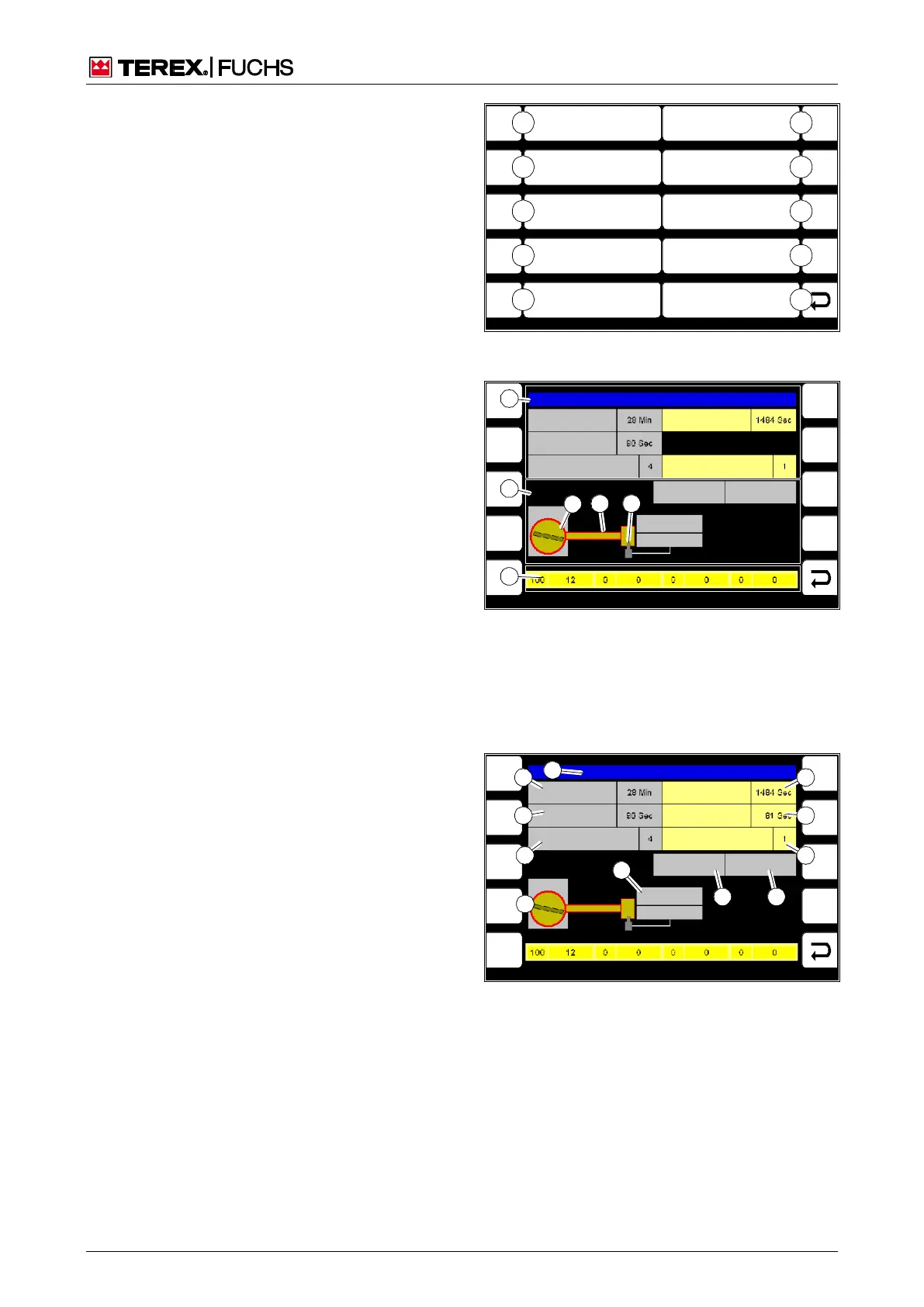

When the diesel engine is running, the display

screen for automatic mode appears (Fig. 78).

The pump runs in accordance with the pa-

rameters displayed (78/1). The status of the

piston detector is monitored during the set

number of pump cycles. If a status change

takes place during these pump cycles (pause

time and pump run time) the piston has

moved in the monitored distributor. If no sta-

tus change takes place, an error message

appears (also in the main control display).

The middle area of the display screen (78/2)

indicates the current operating status of the

pump and piston detector. If the pump is run-

ning or the piston detector changes its status,

the display and text change.

The progress indicator (78/3) shows the ex-

pired and outstanding pump run time and

pause time with colored bars and percent-

ages.

Operating note

The pause time can be terminated. Then the

pump starts.

►

Briefly press side function (79/11) key.

or multifunction button

►

Navigate focus to button (79/11).

►

Briefly press button.

F1

F2

F3

F4

F6

F7

F8

F9

F5

BSB51160

ESC

Lamp Test

Diagnostics Lubrication

LE - Diagnostics

3

2

1

0

4

8

7

6

5

9 CANopen - Diagnostics

OPERATING HOURS

ECU - Diagnostics

Diagnostics Magnet System

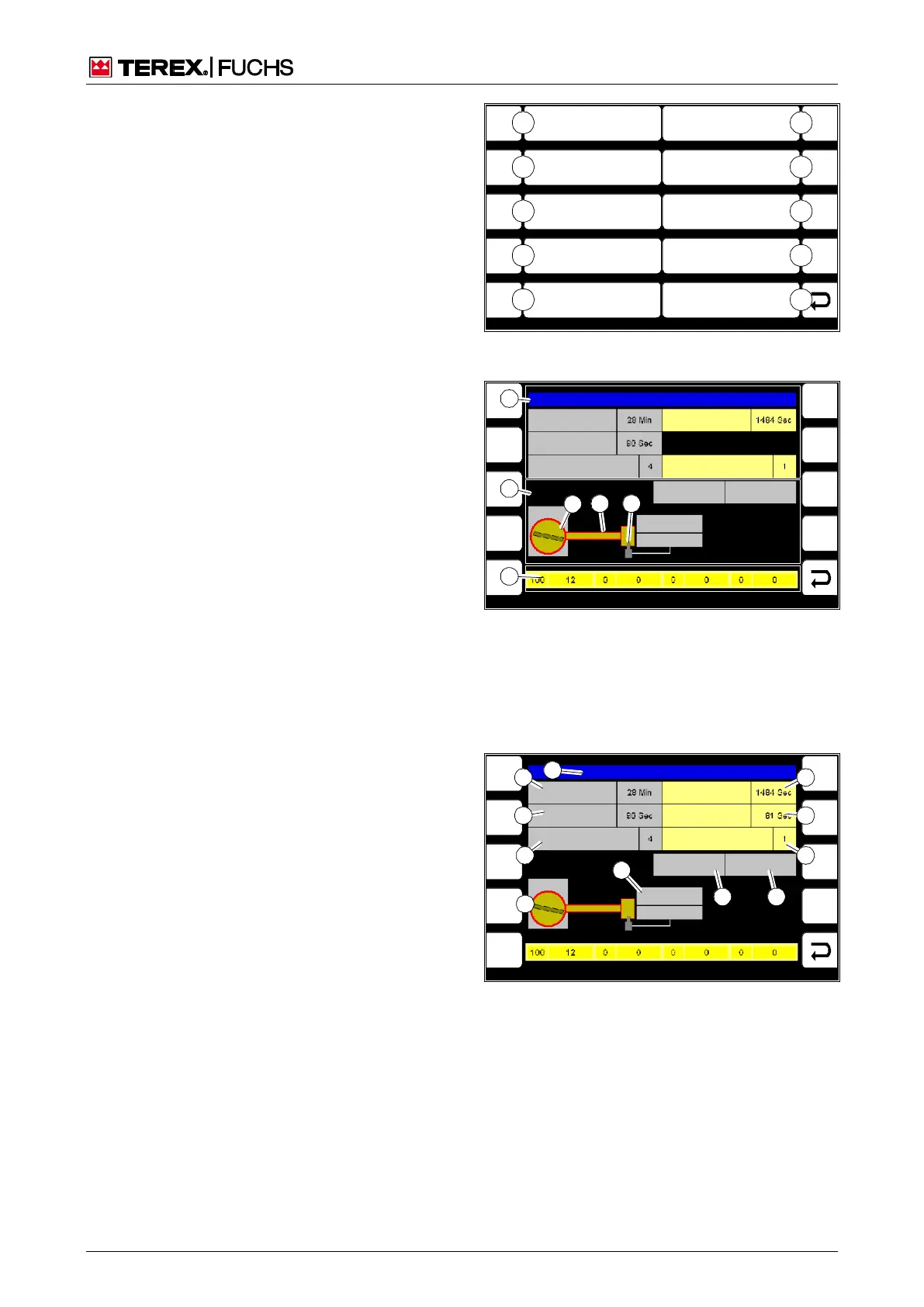

Fig. 77 Diagnostics menu

6 Grease lubrication system diagnostics

F3

F4

F6

F7

F8

F9

F5

F1

F2

BSB50883

4 5 6

1

3

2

Uppercarriage grease lubrication system

Appointed

Pause time

Appointed

Pump run time

Appointed No. of pump runs

With detector monitoring

Remaining

Pause time

Achieved No. of pump runs

With detector monitoring

No. of pump runs

Achieved

Status change

Detected

Pump

Status

Piston detector

HIGH = GR EEN

LOW = G RAY

Fig. 78 Grease lubrication system diagnostics

1 Parameters and cycle status

2 Current operating status

3 Progress indicator

4 Pump

5 Lubricating line

6 Piston detector

F3

F4

F6

F7

F8

F9

F5

F1

F2

BSB50884

Uppercarriage grease lubrication system

Appointed

Pause time

Appointed

Pump run time

Appointed No. of pump runs

With detector monitoring

Remaining

Pause time

Achieved No. of pump runs

With detector monitoring

No. of pump runs

Achieved

Status change

Detected

Pump

Status

Piston detector

HIGH = GR EEN

LOW = G RAY

2

3

4

5

7

9 8

10

1

11

Remaining

Pump run time

6

Fig. 79 Automatic mode

1 Selected grease lubrication system

2 Set pause time

3 Set pump run time

4 Set number of pump cycles with detector monitoring

5 Remaining pause time

6 Remaining pump run time

7 Achieved number of pump cycles with detector moni-

toring

8 Status change detected

9 Number of pump cycles reached

10 Status of piston detector; HIGH= green LOW= gray

6

Grease

lubricati

on

system

diagnos

Loading...

Loading...