7 CARE AND MAINTENANCE

7.20 MHL360 E

7.4.6 Tires

Danger of injury due to machine

movements

• Repair work on the wheels, for

example dismantling tires from

the rim or fitting them onto the

rim, may only be performed by

specialists and with suitable as-

sembly tools.

• When working on the tires make

sure that the machine is parked

safely and has been secured

against rolling away (chocks)!

In an emergency: Administer first

aid, seek treatment from a doctor

►

Check the tires for tears, cuts, foreign bod-

ies, etc.

►

During the first 50 operating hours, check

the torque of the wheel nuts weekly. After

this, check them at regular intervals, tight-

ening to the correct torque if necessary.

Tightening torque: 650Nm

When changing a wheel, always tighten the

wheel nuts to the specified torque crosswise

in several stages.

7.4.7 Oil level check

j

Burns due to hot fluids and sur-

faces

• Oil is hot when the machine is at

operating temperature. Avoid

touching hot oil or parts carrying

oil.

In an emergency: Administer first

aid, seek treatment from a doctor

►

Park the machine on level ground.

►

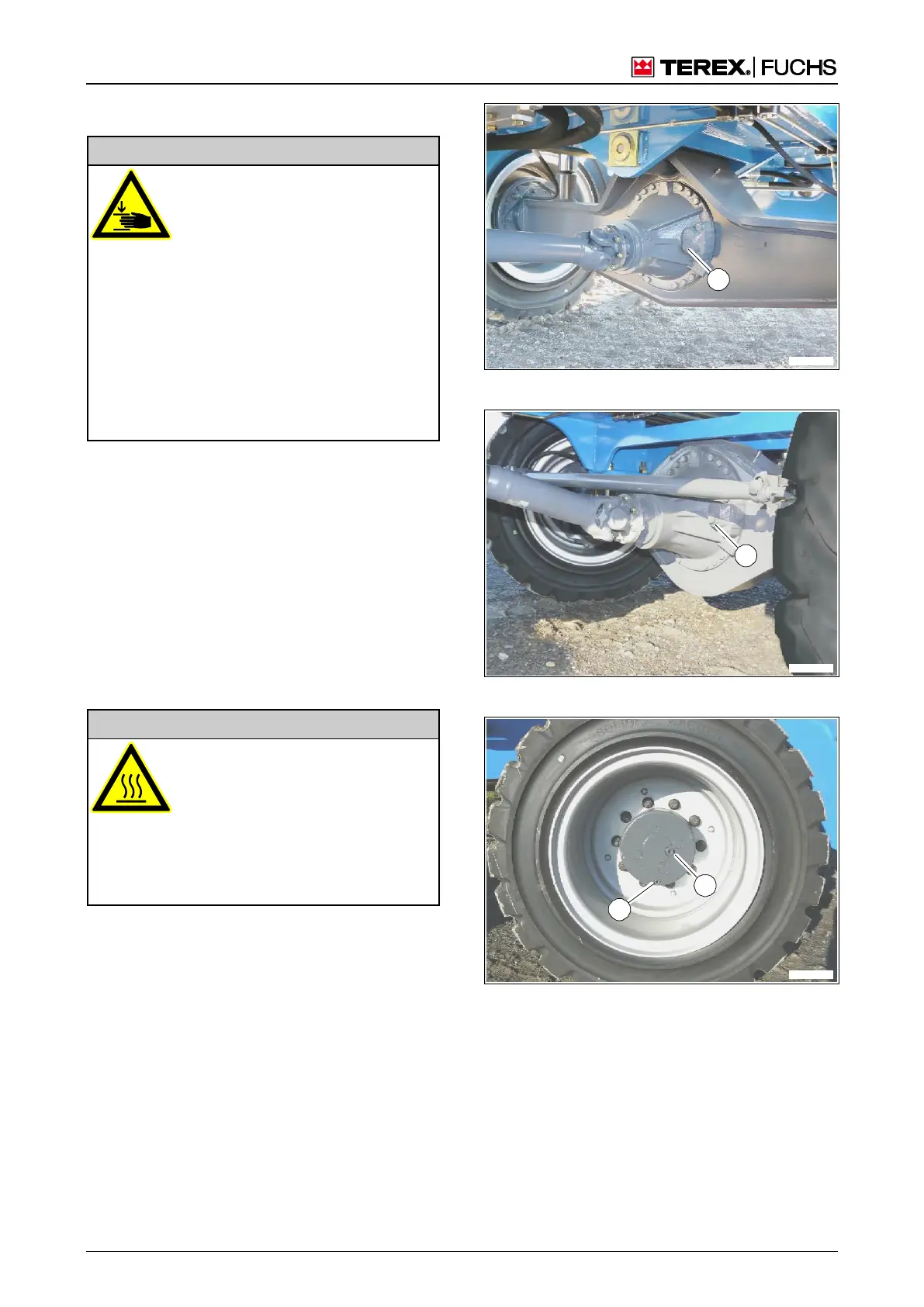

Turn the wheel until the drain plug (265/2)

is at the bottom.

►

Switch off the engine.

►

Remove checking plugs, check and top up

oil if required.

h Chapter 7.3 Fuels, lubricants and coolants

Chapter 7.6.4 Maintenance and inspection

plan

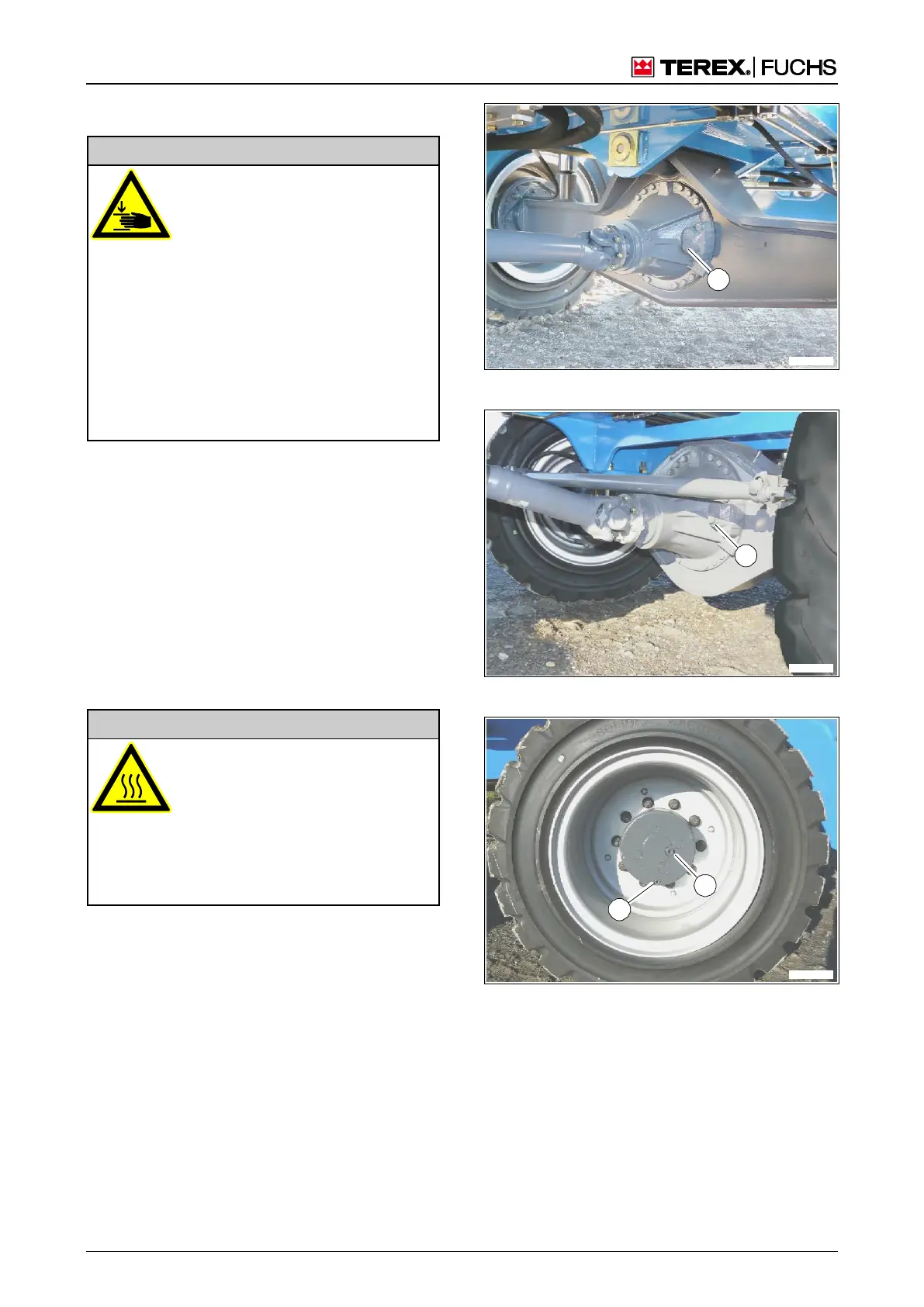

Fig. 263 Rear axle

Fig. 264 Front axle

Fig. 265 Wheel hub

Loading...

Loading...