OPERATION 5

MHL360 E 5.1

5.1 n Safety

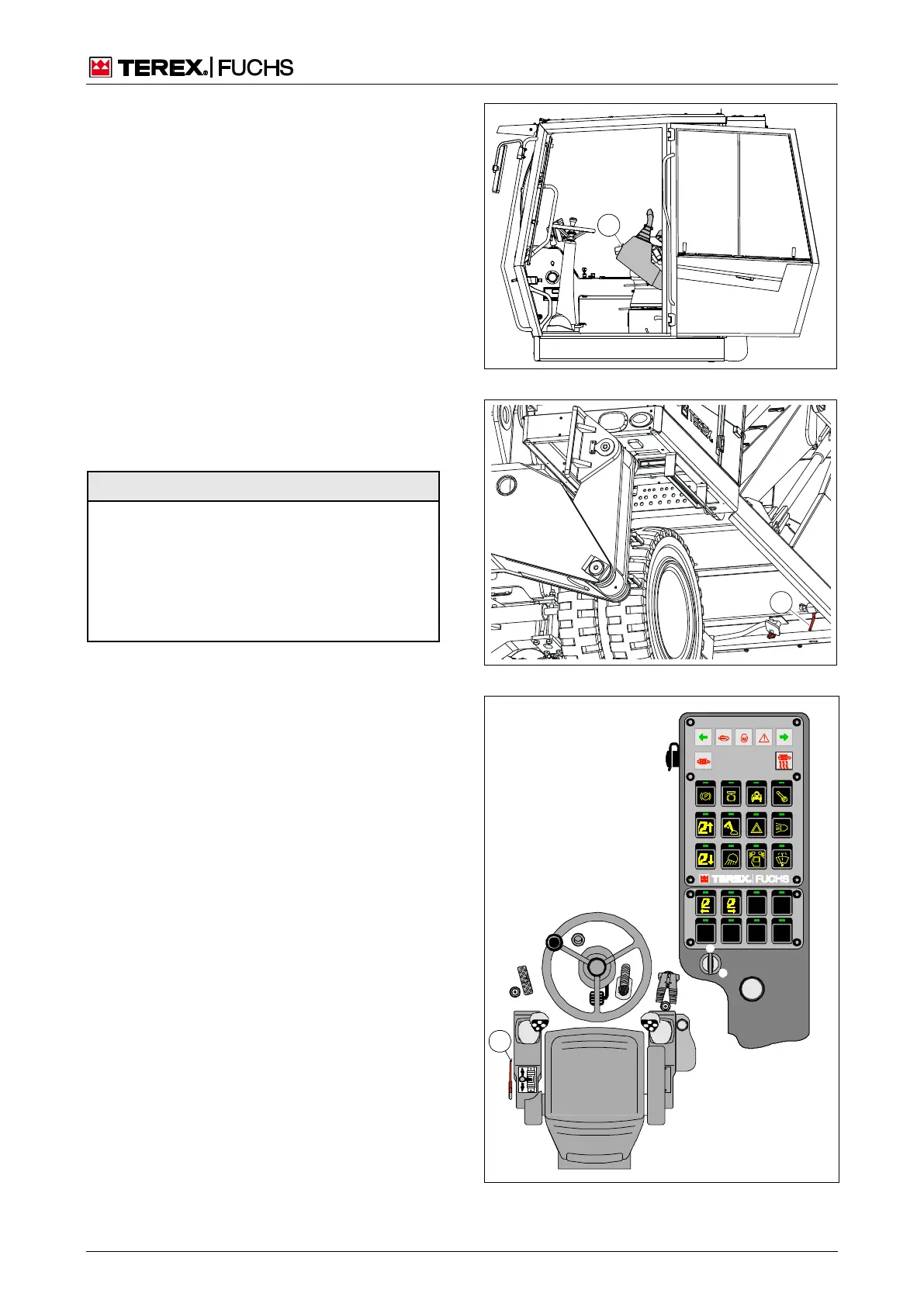

5.1.1 Protection function of the cab

The structural design of the cab provides a

high degree of safety. It cannot however

guarantee complete protection.

The operating personnel are responsible for

ensuring that they buckle themselves in, that

the SWL is adhered to, that work only takes

place on a solid and even surface, and the

loading machine moves in such a way that no

hazardous situations arise.

Additional safety measures are necessary if

material to be loaded could fall in the area of

the cab or if, due to slopes in the terrain, a

toppling loading machine can roll over the

cab.

Damage may impair the structural safety of the

cab. Damaged cab parts may only be replaced

by original parts from the machine manufacturer.

Damage to the steel structure (cracks, buckles,

distortion) must not be repaired. The cab should

be replaced with an original cab from the ma-

chine manufacturer.

5.1.2 Armrest switch

If the left armrest is flipped up, travel and work

functions are disabled. This reduces the dan-

ger of control elements being actuated inad-

vertently. If work operation is interrupted, flip

up the left armrest if possible.

Always flip up the left armrest:

Before standing up from the operator's seat

Before leaving the cab

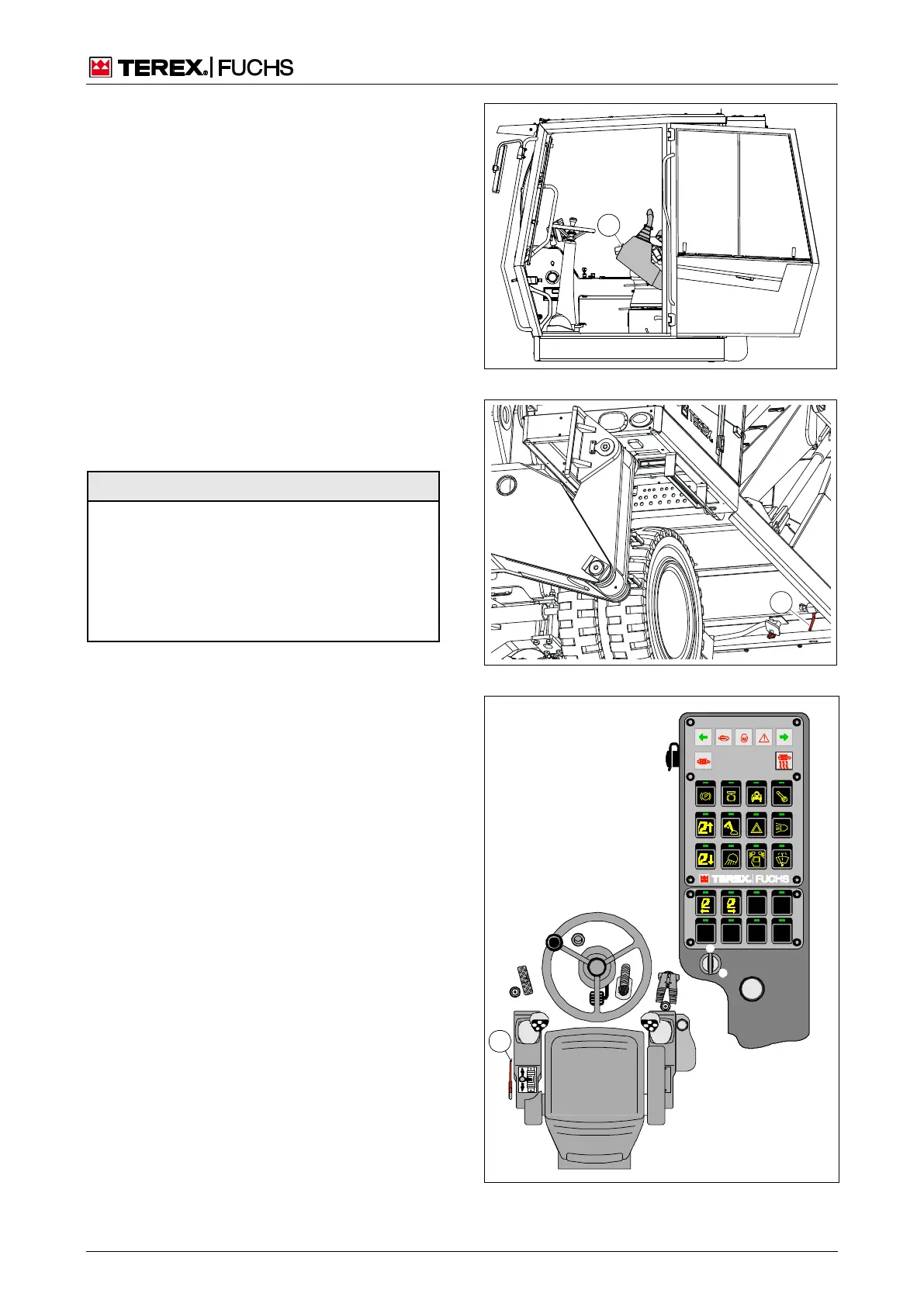

5.1.3 Emergency lowering of cab

If the control for the adjustable cab fails due to

a malfunction in the diesel engine or because

of some other fault, it can be lowered with the

emergency cab lowering function. Depending

on the situation, emergency lowering can be

carried out from inside using the ball valve,

(91/1) or from outside with the ball valve

(90/1).

In order to adjust the cab again after lowering,

the ball valves (91/1) and (90/1) must be re-

turned to the shut-off position.

Fig. 89 Upward folding left armrest

Fig. 90 External emergency lowering

Fig. 91 Internal emergency lowering

Emerge

ncy

lowerin

g of

cab

90

Loading...

Loading...