CARE AND MAINTENANCE 7

MHL360 E 7.25

7.5.1 Automatic central lubrication sys-

tem for uppercarriage, loading

equipment and work attachment

mounting

Various lubricating points are connected to

the automatic, time-controlled central lubrica-

tion system.

h Chapter 7.5 Overview of lubricating points

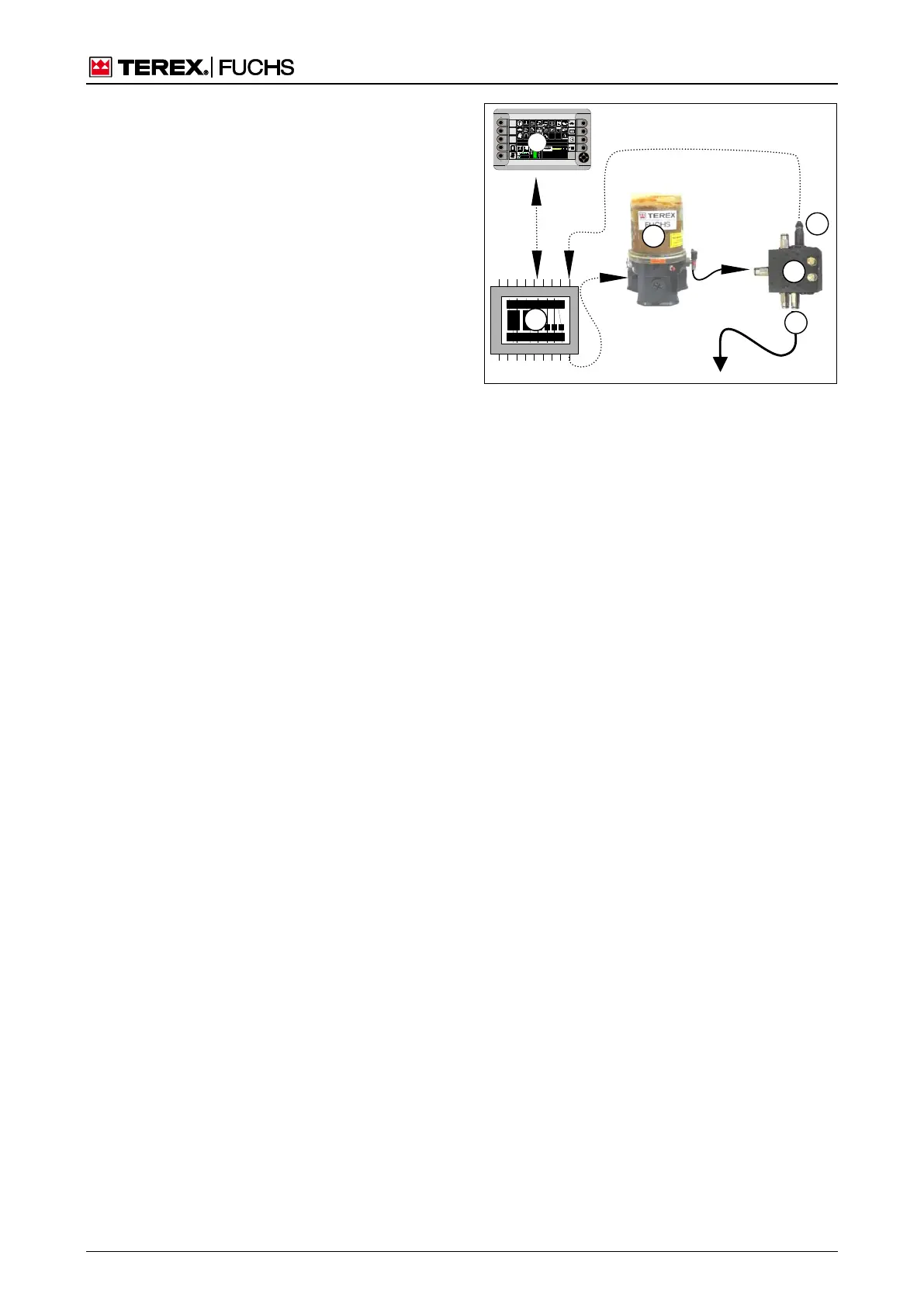

Operating principle

The lubricating pump (273/1), which consists

of a grease reservoir, agitator and pump,

supplies the lubricating points with lubrication

grease via several distributors (273/2).

The main control (273/5) switches the pump

on and off automatically. The pre-set grease

lubrication pause time is 28 minutes. It can

only be changed by a service engineer in the

service menu (273/6). An additional lubrication

cycle can be activated if necessary.

h Chapter 7.5.3.1 Triggering an additional

lubrication pulse

The distributor of lubricants (273/2) transports

the lubrication grease to other distributors and

directly to the lubricating points (273/3) via

pistons. A piston detector (273/4) is connect-

ed to one of the distributors. It detects the

piston movement in the distributor. If no piston

movement is detected within a number of lu-

brication cycles, it is assumed that there is a

fault. An error message appears in the main

control display on the multifunction monitor

(273/6). Automatic lubrication stops.

h Chapter 7.5.3.2 Lubrication when lubricat-

ing pump is faulty

Diagnostics for grease lubrication system

(optional)

The diagnostics function displays the operat-

ing modes, parameters and current status for

central grease lubrication. Pending error mes-

sages can be reset.

h Chapter 4.5.13.6 Grease lubrication sys-

tem diagnostics

F

09:43 11.03.2011

MHLXXX / XXXX

1800 UPM

0 5 10 15 20 25

95°C 75°C

0 ½ 1

9 %

120 0

1

2

4

5

3

6

BSB60015

Fig. 273 Operating principle of central lubrication

system

1 Lubricating pump

2 Distributor

3 Outgoing lubricating pipe to another distributor or a

lubricating point

4 Piston detector

5 Main control

6 Multifunction display

Loading...

Loading...