CARE AND MAINTENANCE 7

MHL360 E 7.75

7.7.23 Angular resolvers (optional)

Risk of crushing from loading

equipment

• Only carry out a visual inspection

when the loading machine is

switched off and its pressure has

been discharged, and when the

loading equipment has been

safely lowered.

In an emergency: Administer first

aid, seek treatment from a doctor

Angular resolvers are precision com-

ponents. When working on the joining

elements, protect the angle transmit-

ter axle (335/2) against forces.

Condition and lubrication

►

Check the external condition of the angular

resolvers (334/1+4) and joining elements

(334/2-3).

►

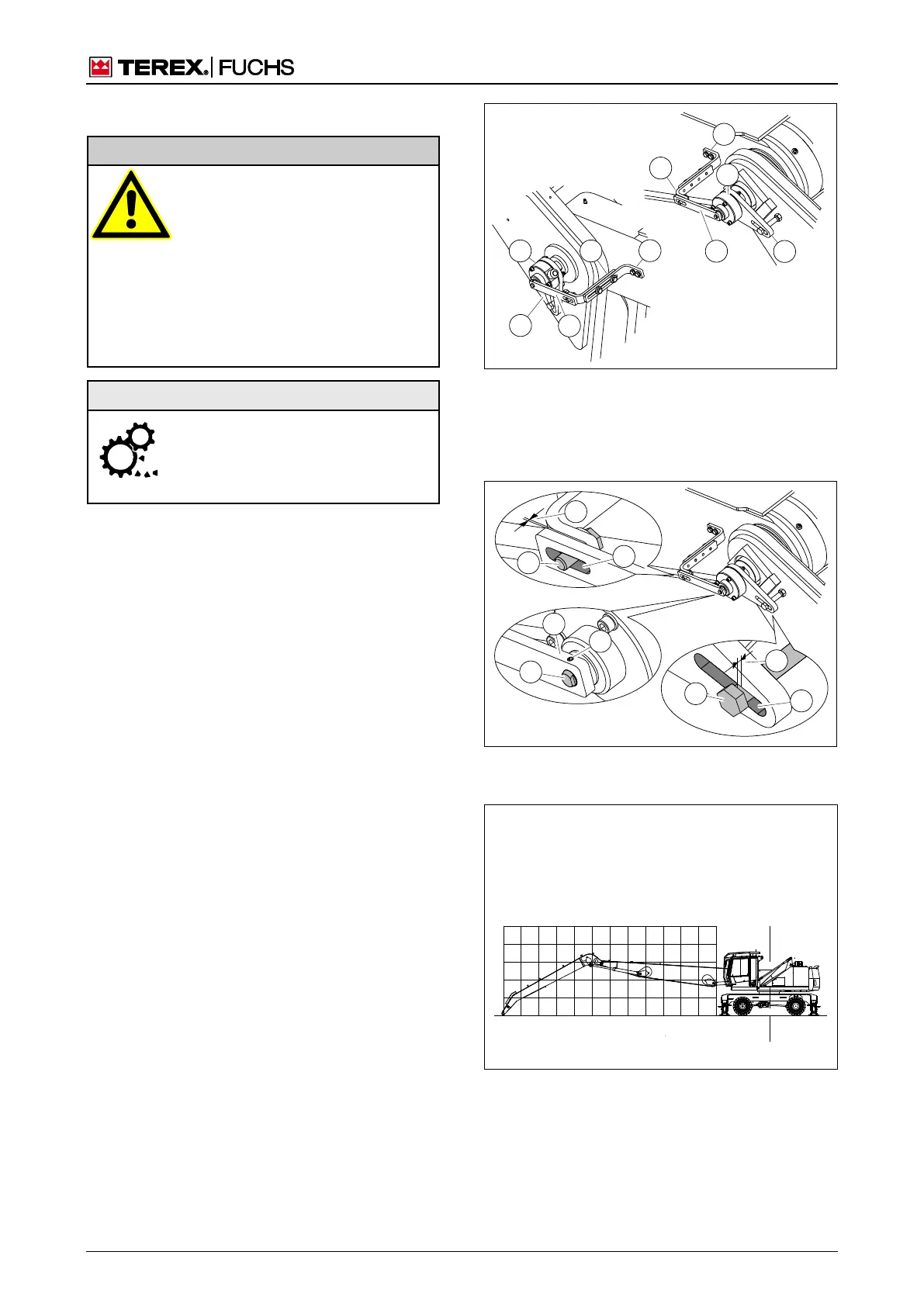

Check that the connection between the clip

(335/1) and angle transmitter axle (335/2) via

the clamping sleeve (335/3) is free from play.

►

Check the pin (335/4) in the elongated hole

(335/5) to ensure it is guided free from play.

►

Check for play between the clips and

brackets. These must not touch one an-

other beyond the area of movement of the

loading equipment.

(335/6): 2±1 mm for boom and dipperstick.

(335/7): varies according to installation sit-

uation, but at least 1 mm.

► Lubricate the elongated holes (335/5).

Function check

►

Open the LE diagnostics display screen.

h Chapter 4.5.13.5 LMB/HRB diagnostics

►

Extend and retract the loading equipment

fully. During this process, pay attention to the

coordinates on the display screen, particularly

when changing direction. The coordinates

must not jump around or remain stationary.

►

Extend and set down the loading equip-

ment on level ground (Fig. 335). The dis-

played position may deviate from the work-

ing range diagram by ±0.25 m.

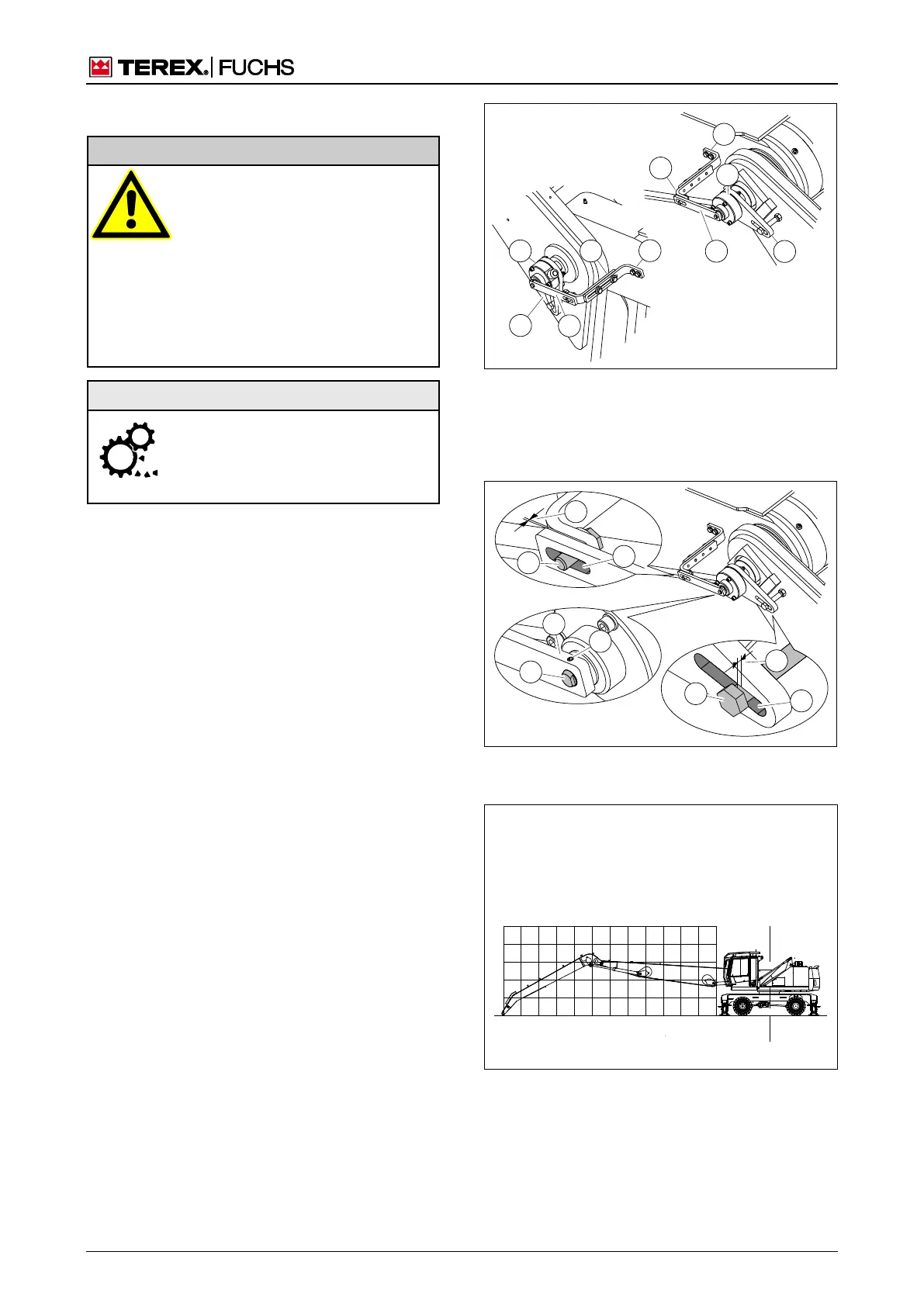

Fig. 334 Angular resolvers

1 Dipperstick angular resolvers

2 Holder

3 Clip

4 Boom angular resolvers

Fig. 335 Angular resolver details (using example of

dipperstick)

Fig. 336 Checking position of coordinate display

Loading...

Loading...