CARE AND MAINTENANCE 7

MHL360 E 7.27

7.5.3.1 Triggering an additional lubrica-

tion pulse

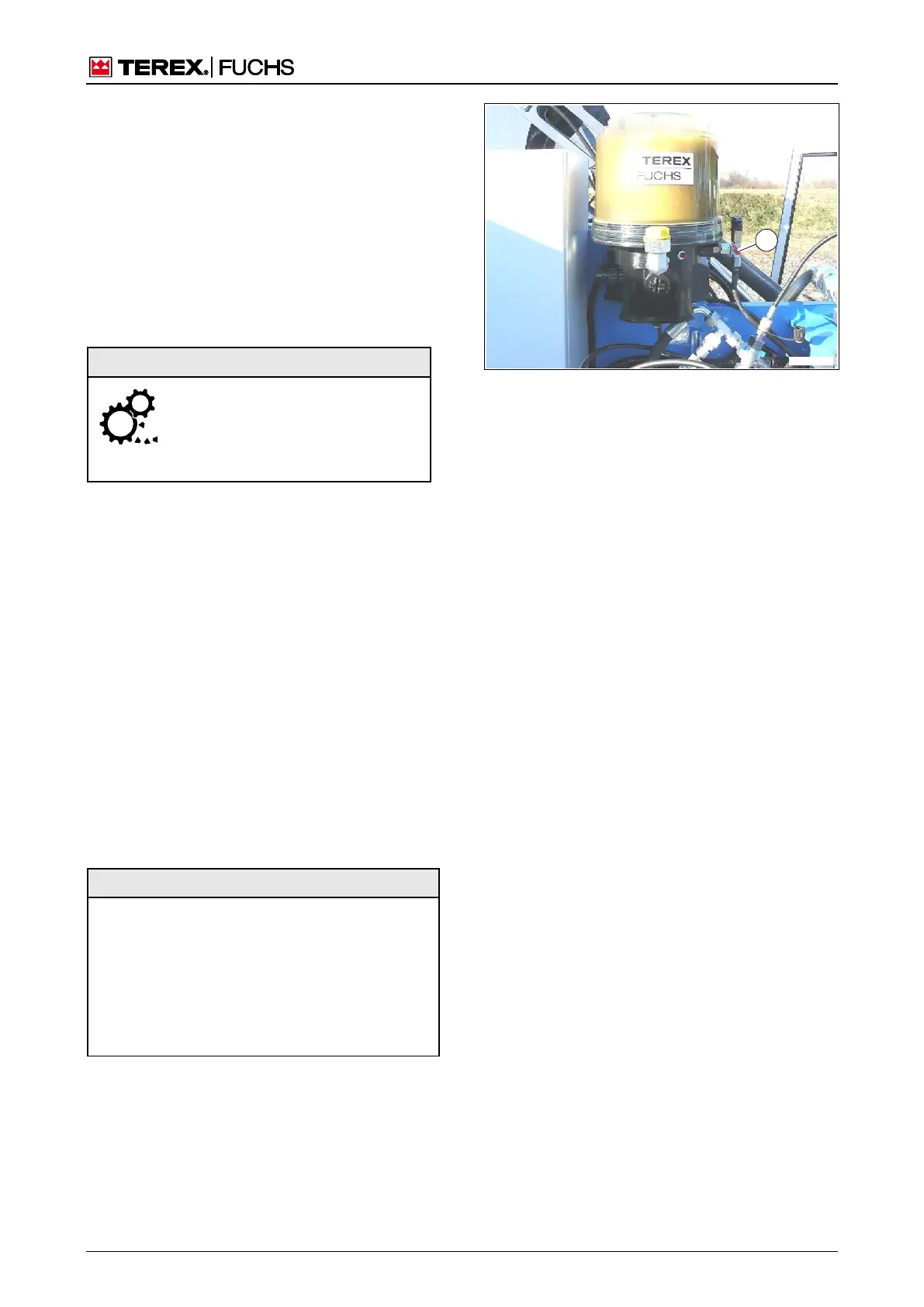

An "additional lubrication pulse" for additional

lubrication of the uppercarriage can be trig-

gered in the function menu using the pushbut-

ton function (275/66), and for the undercar-

riage (optional) using (275/73). The additional

lubrication pulse then runs automatically.

7.5.3.2 Lubrication when lubricating

pump is faulty

If the lubricating pump is defective,

it may cause serious bearing

damage. The lubricating pump

must therefore be repaired imme-

diately.

If the loading machine starts running again on

its own accord for a short period of time, the

lubrication system behind the lubricating

pump should be supplied with grease manual-

ly.

Lubrication interval: every 4 operating hours

►

Attach filler pump to grease nipple (276/1).

►

Pump in lubrication grease until fresh lubri-

cation grease escapes from the boom

bushings and dipperstick bearing, creating

a collar of grease.

If the machine has been operated for several

days without the lubricating pump, grease

must be pumped in until fresh grease escapes

on all bearing points.

7.5.4 Cab door

To ensure that the door can be opened in all

weather conditions, the door seals must be

brushed with talcum or silicone oil at least every

two months or more frequently if required.

Grease the door hinges and door locks regular-

ly. It is essential to wear safety goggles and

suitable protective clothing during maintenance

work.

Fig. 276 Grease nipple

Lubrica

tion

when

lubricati

ng

pump is

Loading...

Loading...