Ergonomic Recommendations

Product Reference Guide

21

Service Access Requirements

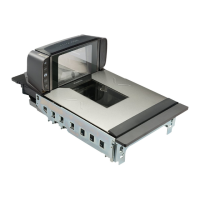

The scanner and scanner-scale have been engineered to allow performance of

all routine service and maintenance (such as “zeroing” and calibration) without

removing the scanner from the checkstand. Additionally all cable connections

made at the scanner can be connected and removed while the unit is sitting on

the countertop. The installer should provide service access to all remaining

cable connectors as well as the AC/DC Power Supply (if installed).

Recommended Power Installation

Since the typical grocery environment includes conveyor belts and electric

motors, care should be taken to ensure that the scanner has a supply of “clean”

power (power without excessive electrical noise).

Liquid Drainage

Select a checkstand design which allows fluids to flow through, and directs liq-

uids away from any electronic equipment or storage areas.

Should a liquid spill occur, ensure that moisture can flow through the check-

stand without pooling.

Leveling

Both flange mount and shelf mount scanners may require leveling during

installation to ensure the platter is flush or just below flush with the counter.

Each type is leveled using different methods:

• Shelf mounted scanners use built-in leveling screws that mount to the

support rail and can be adjusted as needed. These adjustable leveling

screws are adjusted from the top of the scanner with a slotted screw

driver, with the platter removed. They should be adjusted so the platter is

flush with the top of the counter.

• For a flange mount scanner, adjustment screws must be provided by the

user if leveling is required. The leveling screws should be installed where

shown on the counter cutout/ installation page (see

Counter

Cutout, starting on page 27). Similarly to the shelf mount scanner, the

flange mount scanner platter should be adjusted level to the top of the

counter.

Cable Routing

Placement of the scanner-scale should be planned to allow easy access to other

components, as well as optimize communication between the scanner, the POS

terminal and the optional Remote Scale Display. Note that cables may drop

straight down from the scanner’s connector panel, or may be routed along the

unit’s side using the hardware provided. Do not route interface cables near any

electrical motors or other sources of electromagnetic interference.

Remote Scale Display Placement

The customer, and checker in some instances, must be able to easily view and

read the Remote Scale Display (if one is present). Ambient light and mounting

height considerations are discussed later in this section.

Loading...

Loading...