(5) In spect sta ndard size of cr ankshaft bearing

shells.

(6) In spect cr ankshaft bearing cap.

(7) Mount crankshaft radially.

(8) In spect cr ankshaft bearing play.

NOTE: Radial mounting of the main bearings of

standard size crankshaft is possible by assigning

the color-coded bearing shells.

ASSIGN CRANKSHAFT BEARING SHELLS

The oil pan rail of th e cylinder block is ma rked

with chisel punches indicating what bea ring shell are

used.

(9) Assign cra nksh aft bear ing shells.

(10) Mount crankshaft a xia lly.

(11) In spect cr ankshaft bearing play.

REMOVAL

(1) Remove en gin e (Refer to9-ENGINE-

REMOVAL).

(2) Remove t iming case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(3) Remove en d cover. (Refer t o 9 - E NGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - RE AR -

REMOVAL).

(4) Remove pist ons (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD -

REMOVAL).

CAUTION: The crankshaft bearing caps are num-

bered consecutively, beginning with the first crank-

shaft bearing cap at the front of the engine.

Attention must be paid to the way crankshaft bear-

ing caps fit.

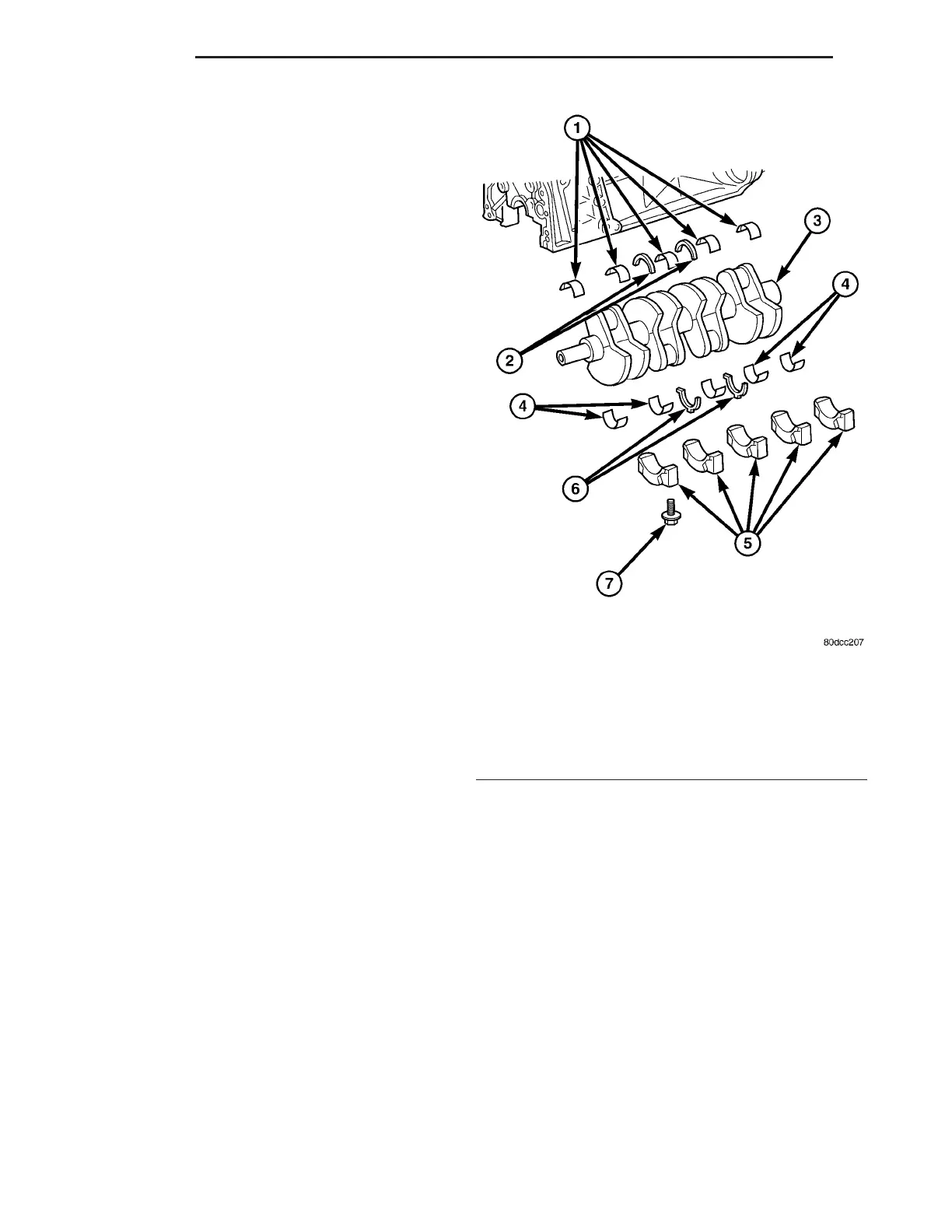

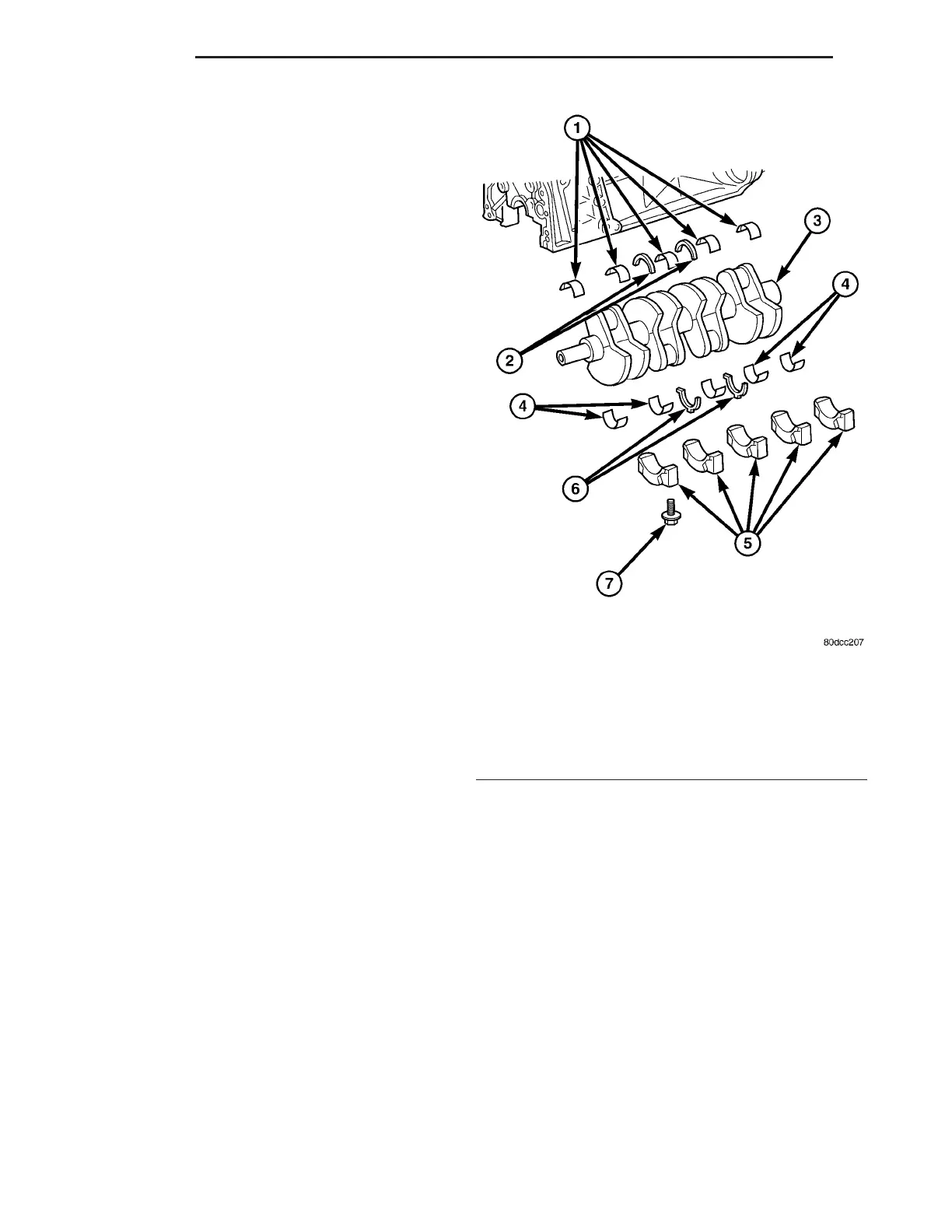

(5) Unbolt cra nksh aft bear ing caps (Fig. 32).

(6) In spect crankshaft bearing caps and bolts for

wear and st retch ing.

(7) Remove crankshaft.

INSTALLATION

CAUTION: Oil the bearing shells before inserting

crankshaft.

CAUTION: Oil grooves in the thrust washers must

point toward the thrust collars of the crankshaft.

CAUTION: Thrust washers in the bearing cap each

have two retaining lugs as a anti-twist lock.

Fig. 32 CRANKSHAFT ASSEMBLY

1 - BEARING HALVES IN ENGINE BLOCK

2 - THRUST WASHERS IN ENGINE BLOCK

3 - CRANKSHAFT

4 - BEARING HALVES IN MAIN BEARING CAPS

5 - MAIN BEARING CAPS

6 - THRUST WASHERS IN MAIN BEARING CAPS

7 - MAIN BEARING BOLTS

9 - 40 ENGINE VA

Loading...

Loading...