Distance between middle

connecting rod bore to

connecting rod bushing

bore

148.970 mm to 149.030

mm

Allowable out-of-round-

ness and taper of basic

bore

.020 mm

Allowable twist of con-

necting rod bearing bore

to connecting rod bush-

ing bore over a length of

100 mm

.100 mm

Allowable variation of

axial parallelism of con-

necting rod bearing bore

to connecting rod bush-

ing bore over a length of

100 mm

.045 mm

Allowable difference in

weight of complete con-

necting rod of an engine

2g

Connecting rod inner

bushing

30.018 to 30.024 mm

Connecting rod outer

bushing

32.575 mm to 32.600

mm

Connecting rod basic

bore

32.500 mm to 32.525

mm

Piston pin play in con-

necting rod

.018 mm to.024 mm

Peak-to-Valley height

(Rz) of connecting rod

bushing on inside

5

Connecting rod bolt

thread

M8 x 1

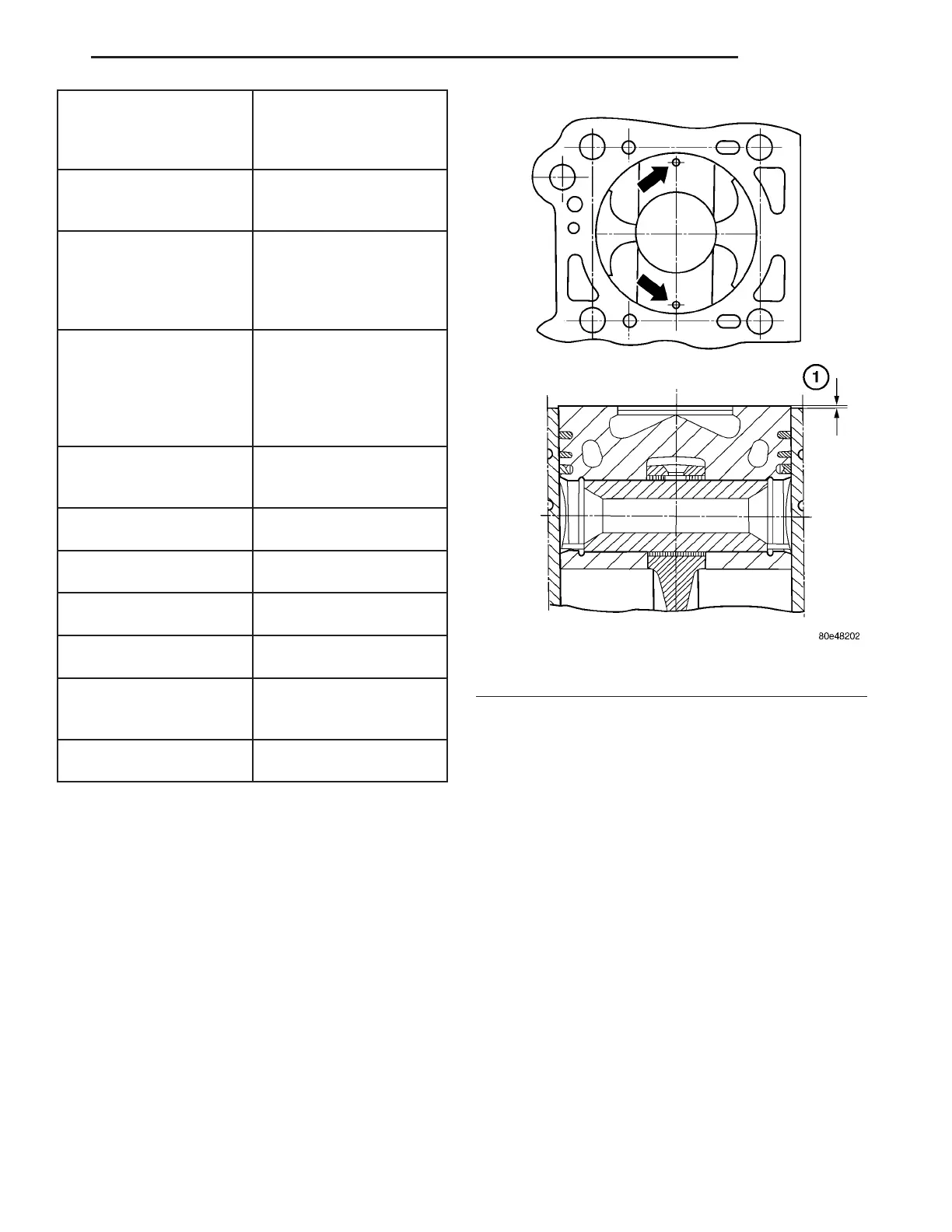

STANDARD PROCEDURE - MEASURING PIS-

TON PROTRUSION

After repla cing t he pistons/connecting rods or

machinin g the engine block con tact surface, it is th en

necessar y to measur e the piston prot rusion .

Measur e protr usion bet ween piston cr own and cyl-

inder hea d contact surface without the hea d ga sket

insta lled. Th e measur ment must be carried out in

the dir ection of the piston pin in order to elimin ate

piston rock.

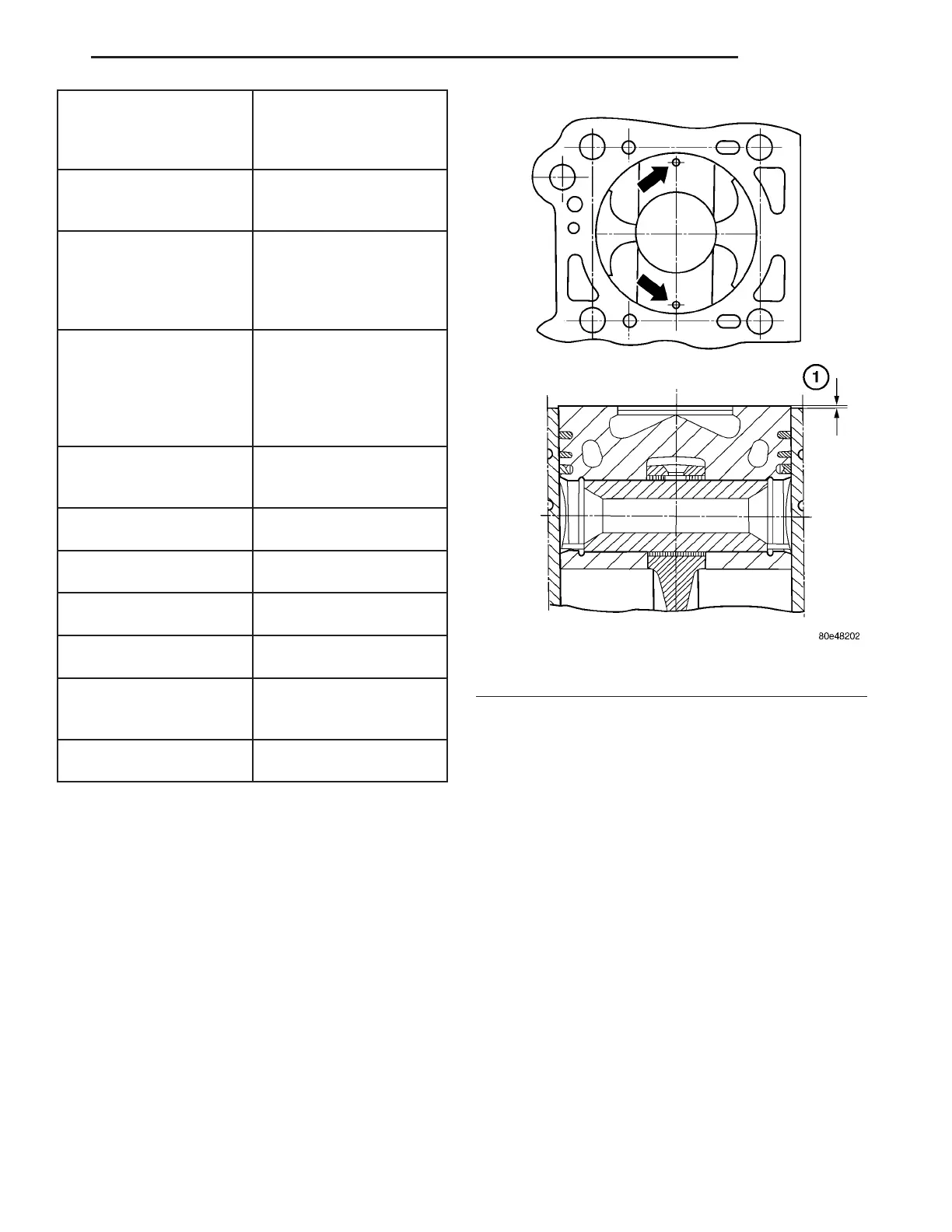

(1) Measur e piston pr otrusion at the two measur-

ing point s (a rrows) (Fig. 39).

Piston protrusion with new cran kcase should be

0.38 - 0.62 m m .

REMOVAL

(1) Disconn ect the n egat ive battery cable.

(2) Remove the engine (Refer t o9-ENGINE-

REMOVAL).

(3) Remove the cylin der head (Refer to 9 -

ENGINE/CYLINDER HE AD - REMOVAL).

(4) Remove t he oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(5) Push back on the ch ain tensioner a nd remove

the oil pump chain from th e oil pu mp.

(6) Remove the oil pu mp.

NOTE: Mark the connecting rod and connecting rod

bearing cap to each other at the inlet side.

(7) Remove the connect ing rod bea ring cap.

NOTE: Do Not mix up the top and bottom connect-

ing rod bearing shells.

(8) Mark the connect ing rod bearing shell a nd th e

connect ing rod bea ring cap to each oth er.

Fig. 39 MEASURING PISTON PROTRUSION

1 - PISTON PROTRUSION MEASUREMENT

VA ENGINE 9 - 47

Loading...

Loading...