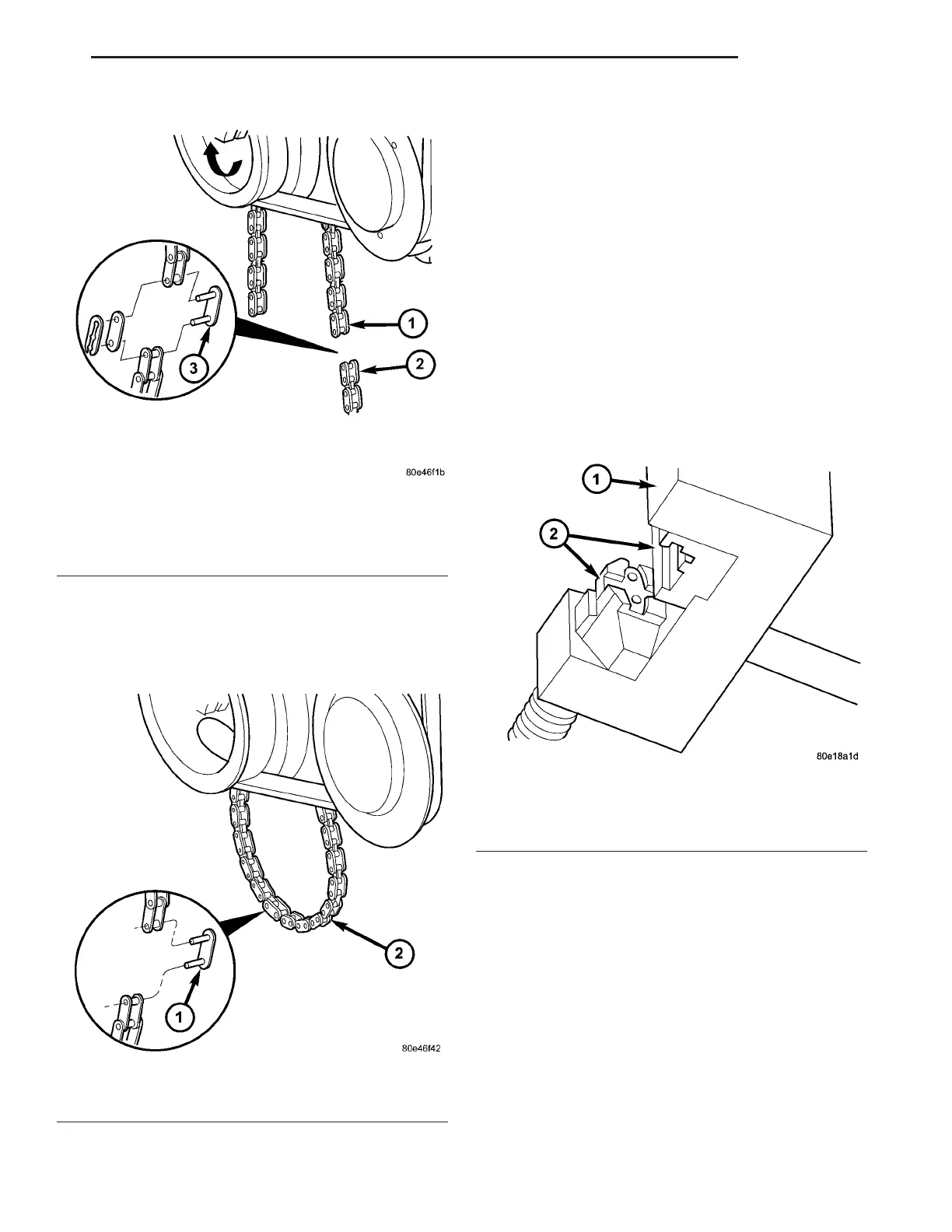

CAUTION: Insert new riveted link from the rear.

(4) Connect en ds of n ew oil pu mp ch ain wit h new

riveted link (Fig. 63).

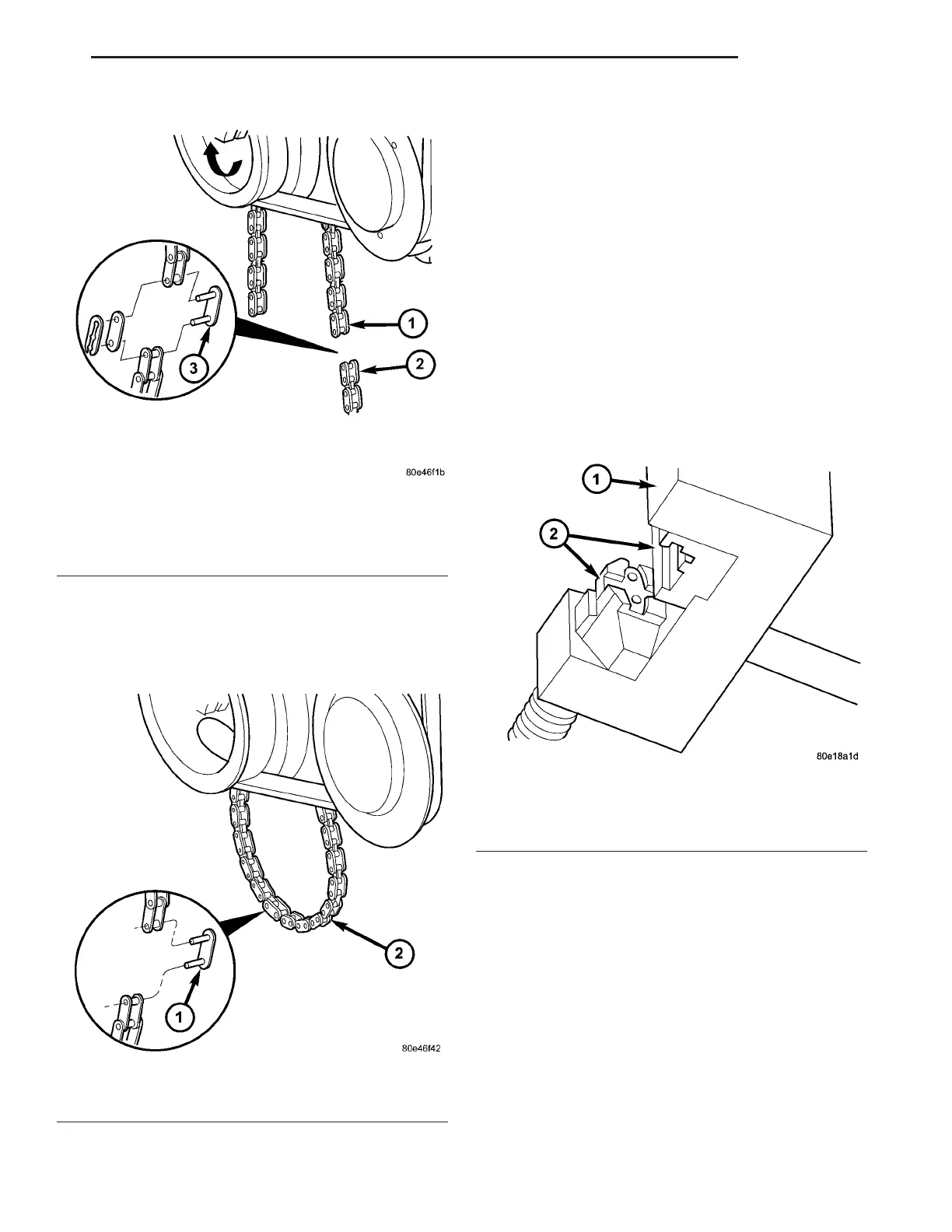

NOTE: When assembling riveting tool, one piece is

secured by a screw and the other can move loosely

on the thrust spindle.

NOTE: The outer plate will be held in place by a

magnet.

(5) Pla ce new ou ter plate in to tool in ser t.

NOTE: Ensure that the riveted link and riveting tool

are aligned.

(6) Position rivet ing tool over new link an d pr ess

in new rivet as far as the tool stop.

(7) Remove riveting tool t o chan ge insert s.

(8) In st all in ser t on riveting tool and secu re with

scr ew.

(9) In st all inser t on rivetin g tool (Fig. 64).

NOTE: The outer plate is held in place magnetically

by riveting tool.

(10) Insert n ew outer plate into th e moving assem-

bly in ser t .

(11) Position riveting tool so tha t spacer webs of

the guide are side by side.

(12) Ensure that rivet ed link an d outer plate ar e

aligned.

NOTE: When turning spindle of riveting tool, be

sure that pins of riveted link are inserted into holes

of outer plate.

(13) Screw in spin dle of r ivet ing tool u ntil firm

resistance is felt.

Fig. 62 REMOVING OIL PUMP CHAIN TEMPORARY

LINK

1 - NEW OIL PUMP CHAIN

2 - OLD OIL PUMP CHAIN

3 - TEMPORARY LINK

Fig. 63 INSTALLING NEW RIVETED LINK

1 - NEW RIVETED LINK

2 - OIL PUMP CHAIN

Fig. 64 INSTALLING RIVETING INSERTS INTO

RIVETING TOOL

1 - SPECIAL TOOL #9312-1

2 - SPECIAL TOOL #9312-5 and #9312-9

VA ENGINE 9 - 63

Loading...

Loading...