Steps in an Analysis

1.3 Steps in an Analysis

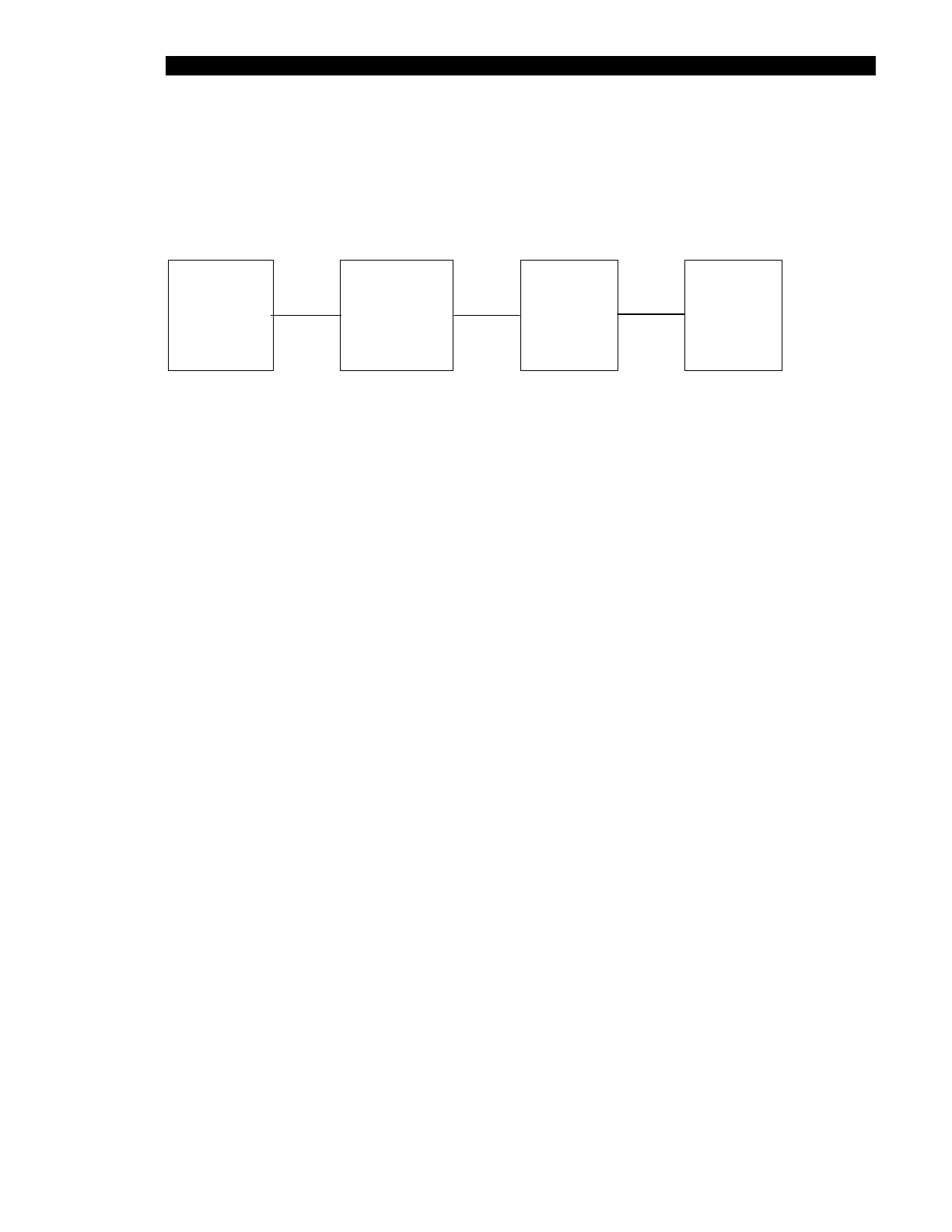

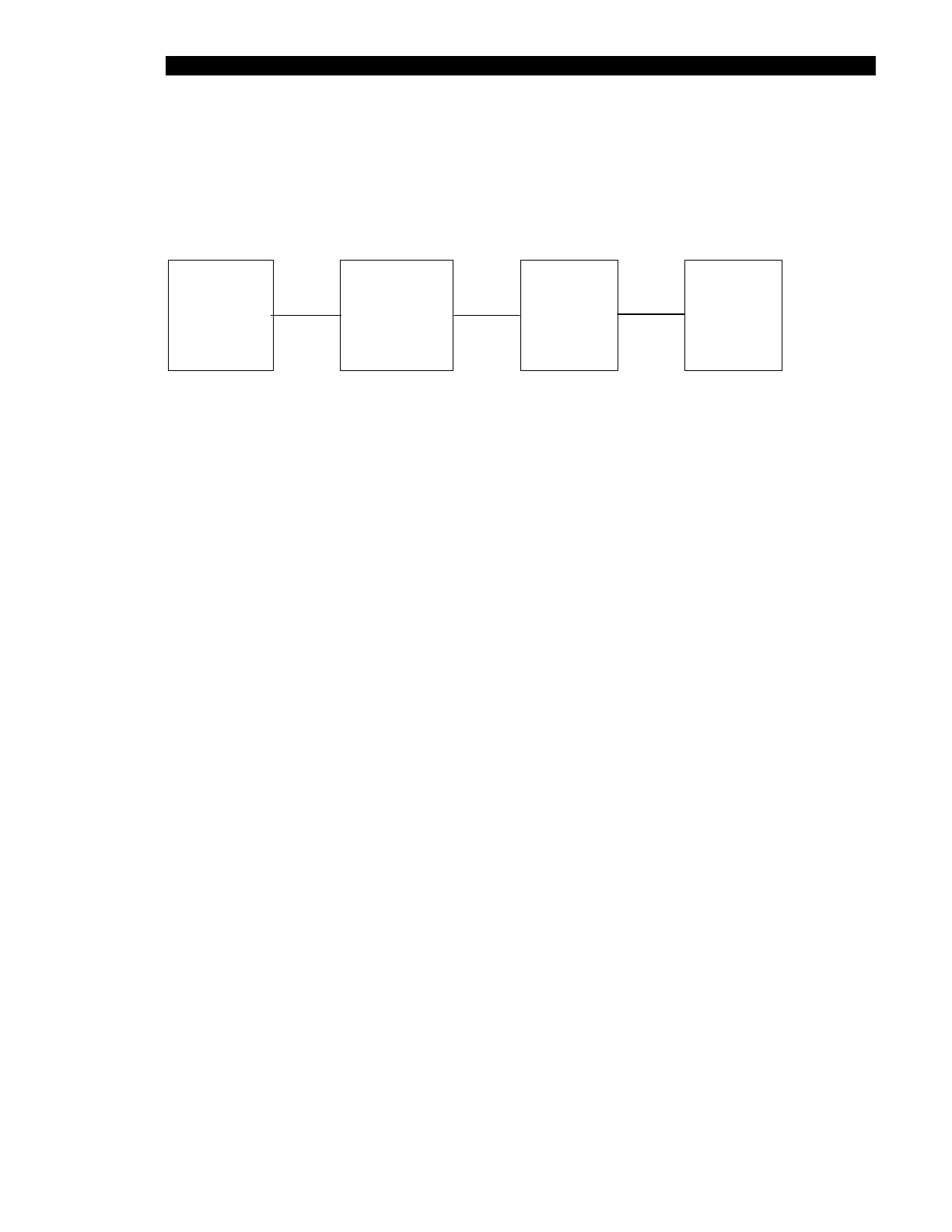

In a typical assay, the operations shown in Figure 1-2 are performed under computer control.

In some cases, two (or more) additional, incubation or wash cycles may be required for an

analytical procedure.

ADDITION OF

SAMPLES,

REAGENTS,

STANDARDS,

DILUENTS,

AND

CONTROLS

INCUBATION

WASHING

DETECTION

Figure 1-2 Operation Steps of the DSX™ Automated ELISA System

1 Addition of Samples, Reagents, Standards, Diluents and Controls to the

Plates

The automated pipette is used to withdraw the appropriate amount of sample,

reagent, standard, diluent or control from tubes (bottles) that are located in the

workspace and add the liquid to the appropriate wells. Pipetting is performed by

custom designed disposable pipette tips to assure pipetting precision and eliminate

the possibility of cross contamination.

All movement of the pipette tip, as well as replacement of pipette tips is performed

under computer control.

2 Incubation

Once the sample, reagents, diluents and standards have been added to each well,

the microplate is placed in an incubator module that is set to a specific temperature

(from 7 °C above ambient to 50 °C) for the appropriate period of time. If desired,

the microplate can be shaken during the incubation

3 Washing

After the incubation is complete, the microplate is moved to the wash module and

is washed. Eight wells of a microplate can be washed simultaneously, and different

wash cycles can be used on different columns on a microplate.

4 Detection and Calculation

The absorbance module measures the optical density of each sample, which is used

to calculate the concentration of the compound of interest in each sample on the

microplate. In addition, QC operations on raw data as well as curve fitting can be

performed to provide the desired results.

DSX™ System Service Manual 1-3

Loading...

Loading...