K117sm7e2

7-25

7. 2. 2.10 Dirt on the back of the print

Check the following matters with the Test Pattern No.1 S(0) and No.4 S(0).

If necessary use other Test Patterns.

Cause Checking

order

Checking Result Treatment

1 Try to readjust each image creation

component according to [7.2.1 Basic

Image Adjustment].

Is the problem fixed?

Yes OK

Transfer

Guide Plates

2 Are Transfer Guides or the black rubber

area of the guide plate near Transfer /

Separation Corona dirty with the toner?

Yes Clean them.

After that, check the distance

between Transfer Guide and

Drum. (It should be 0.5 to

0.7mm.)

Developer Unit 3 Is too much toner accumulating under

the Developer Roller?

Yes Clean the Developer Unit.

Machine inside 4 Is the inside of the machine dirty with

the toner?

Yes Clean it, and also find where

the toner came.

Fuser Unit 5 Is the Guide Plate at the entrance of

Fuser Unit dirty with the toner?

Yes Clean it.

Are Fuser Roller and Pressure Roller

dirty with the toner?

Yes Clean them

7. 2. 2.11 Defective fusing

Check the following matters with the Test Pattern No.1 S(0) and No.3 S(0).

If necessary use other Test Patterns.

Cause Checking

order

Checking Result Treatment

Fuser Unit 1 Is the Fuser Roller properly heated up

after turning on the machine?

No Refer to [7. 1. 2. 1 Fuser

Error (E-001, E-002 &

E-004)] to check the Fuser

Unit.

Paper 2 Is the type of paper selected on the UI

same with that of actually installed

paper?

No Select the correct paper type

on the UI.

Can you fix the problem if you use a

newly unpacked paper?

Yes 1. If the paper was

humidified, instruct the

customer of the way store

the paper.

2. If the paper was not the

specified one, explain the

customer that some

image problem may

occur in that case.

Fusing temperature

setting

3 Does the fusing temperature specified

in the Service Mode suits with the

weight (gram/square meter) of paper?

Yes Is there any part which is

burnt? Replace that part if

burnt.

No Set the fusing temperature

correctly.

Fusing pressure

(Nip)

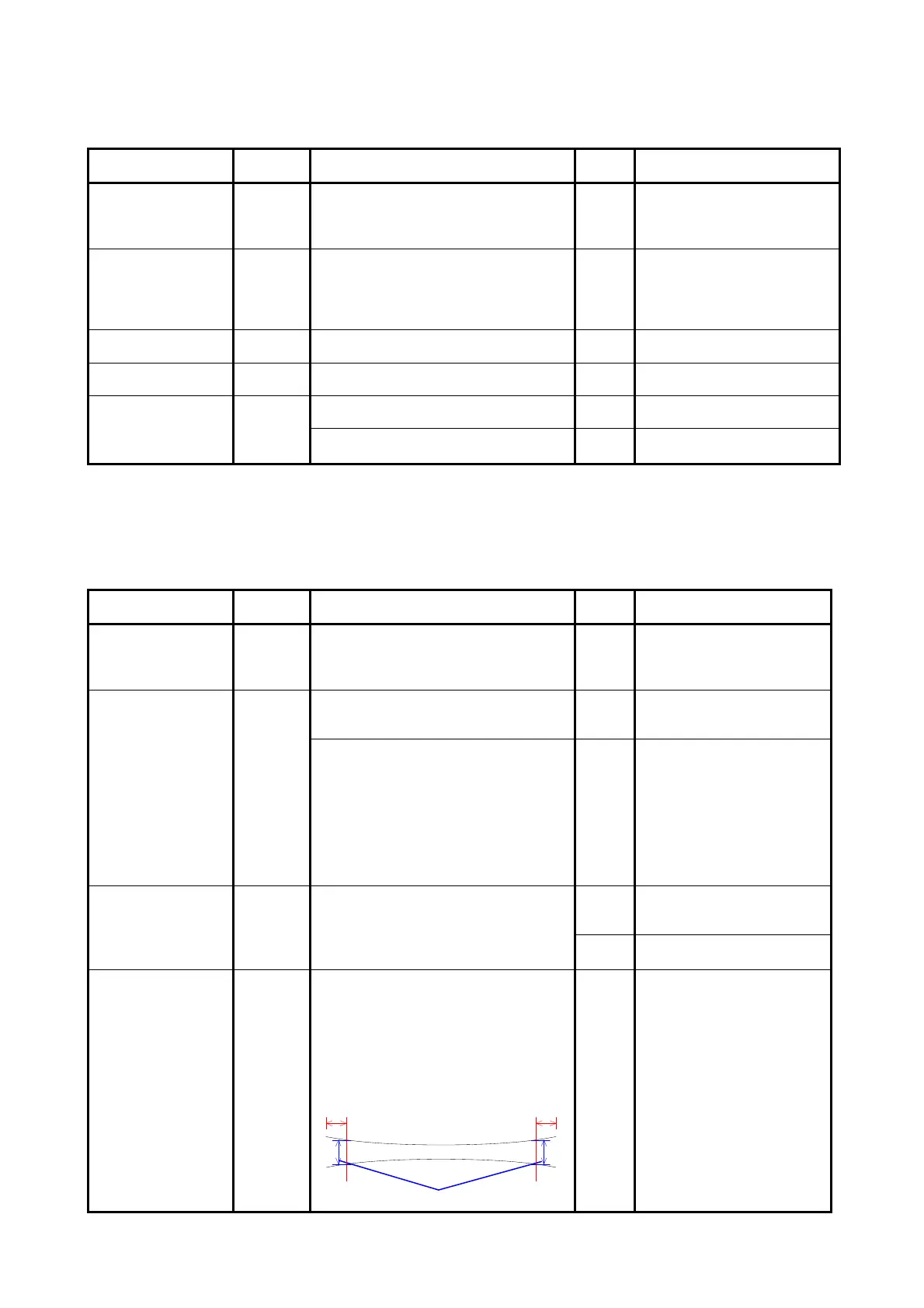

4 Print the Test Patter No.2 S(0) with a

tracing paper (36” or A0), and turn off

the machine in the middle of printing.

Remove the print from the machine and

check the “nip width”.

Is it 8.5 to 9.0mm?

(Measure at 2 mm from the edge.)

2mm 2mm

8.5 to 9.0mm

No Adjust the fusing pressure

correctly.

Loading...

Loading...