K117sm3e1

3-18

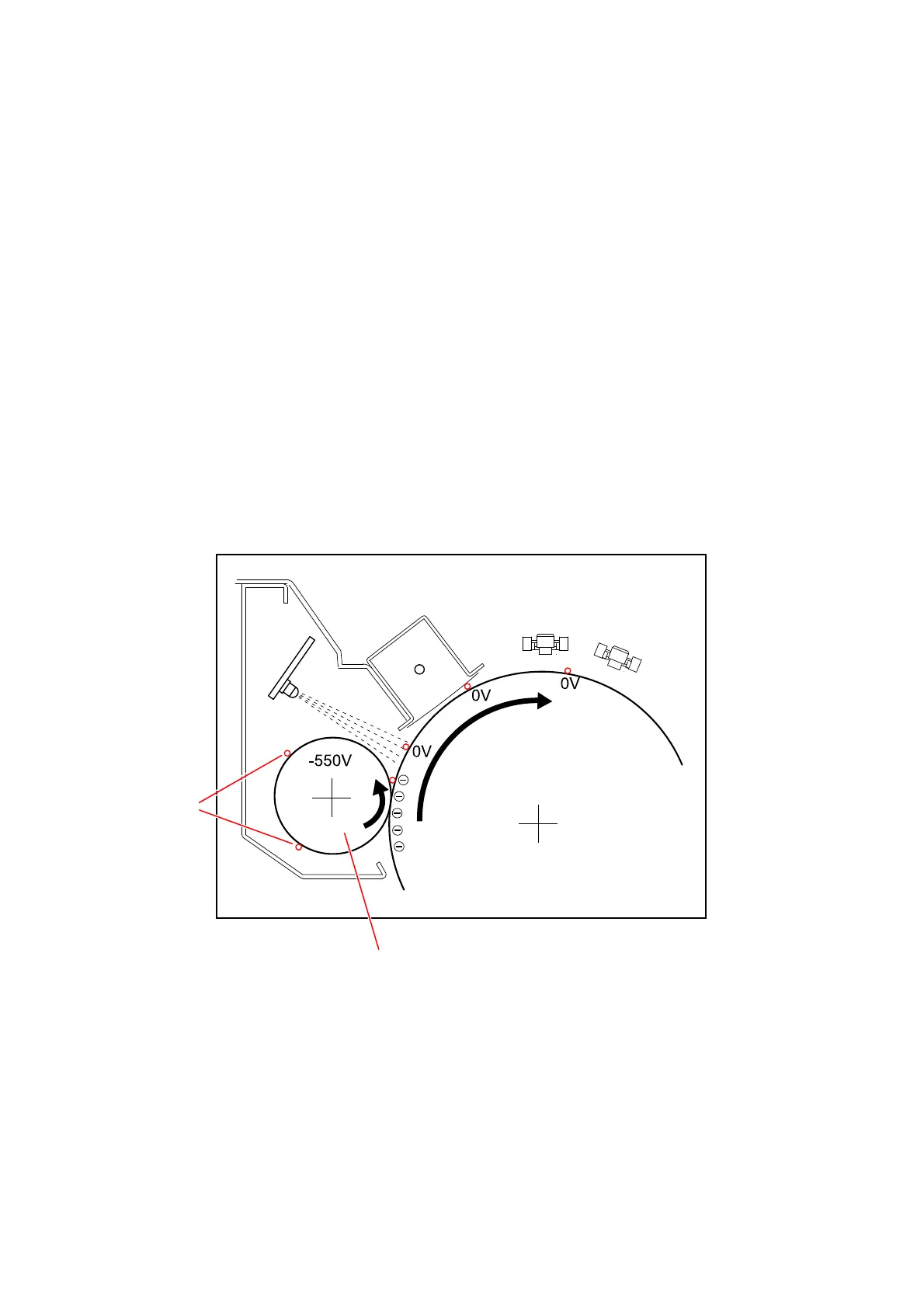

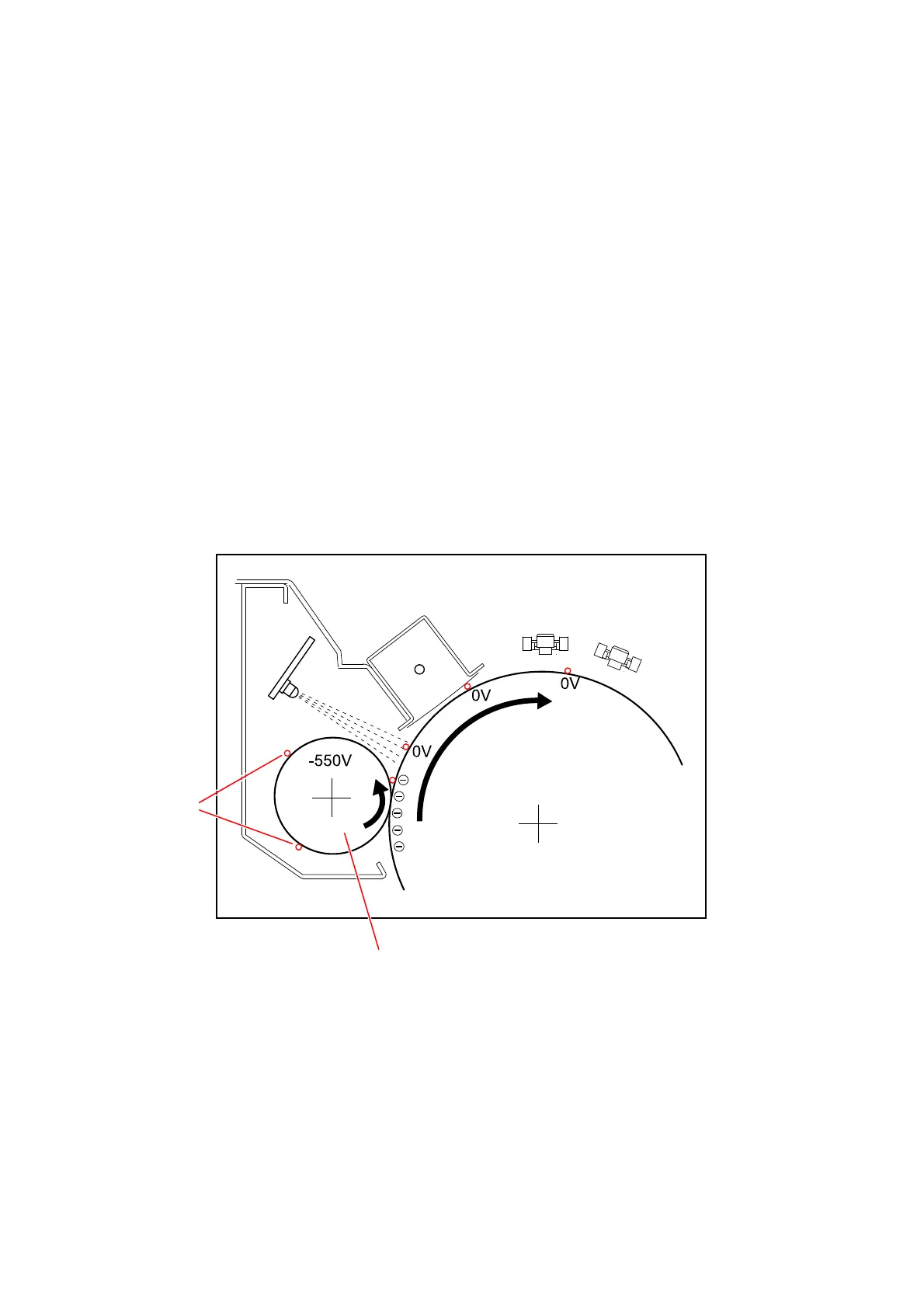

3. 1. 4 Toner Collection Process

As explained in [3.1.2.7 Drum Cleaning], the Cleaning Roller is supplied with +450V to remove the

remained toner from the Drum during the print cycle.

This toner gathered by the Cleaning Roller is returned to the Developer Unit in the following 3

cases.

(1) When the printer has finished printing out all the accumulated print jobs and then going to

stop.

(2) When the used roll paper is ended and changed with another one.

(3) When the used roll paper is changed from one to another because the print size specified in

the job is different.

This process to return the toner is called “Toner Collection Process”.

When the trailing edge of the last sheet passes over the Separation Area, the printer will take the

Toner Collection Process as follows rotating the Drum for 2 revolutions.

1. The Eraser Lamp throws light onto the Drum to remove the negative electric charges from

the Drum. The potential of Drum becomes 0V.

2. The voltage supplied to the Cleaning Roller is changed to -550V in the Toner Collection

Process.

As the potential of Drum becomes higher than that of Cleaning Roller, toner on the Cleaning

Roller moves onto the Drum.

Cleaning Roller

Drum

Remained toner

Loading...

Loading...