K117sm7e2

7-26

7. 2. 2.12 Defective image placement, No Leading Edge

Correct leading margin is 5mm (+/-2mm).

Check the following matters with the Test Pattern No.1 S(0) and No.7 S(0).

If necessary use other Test Patterns.

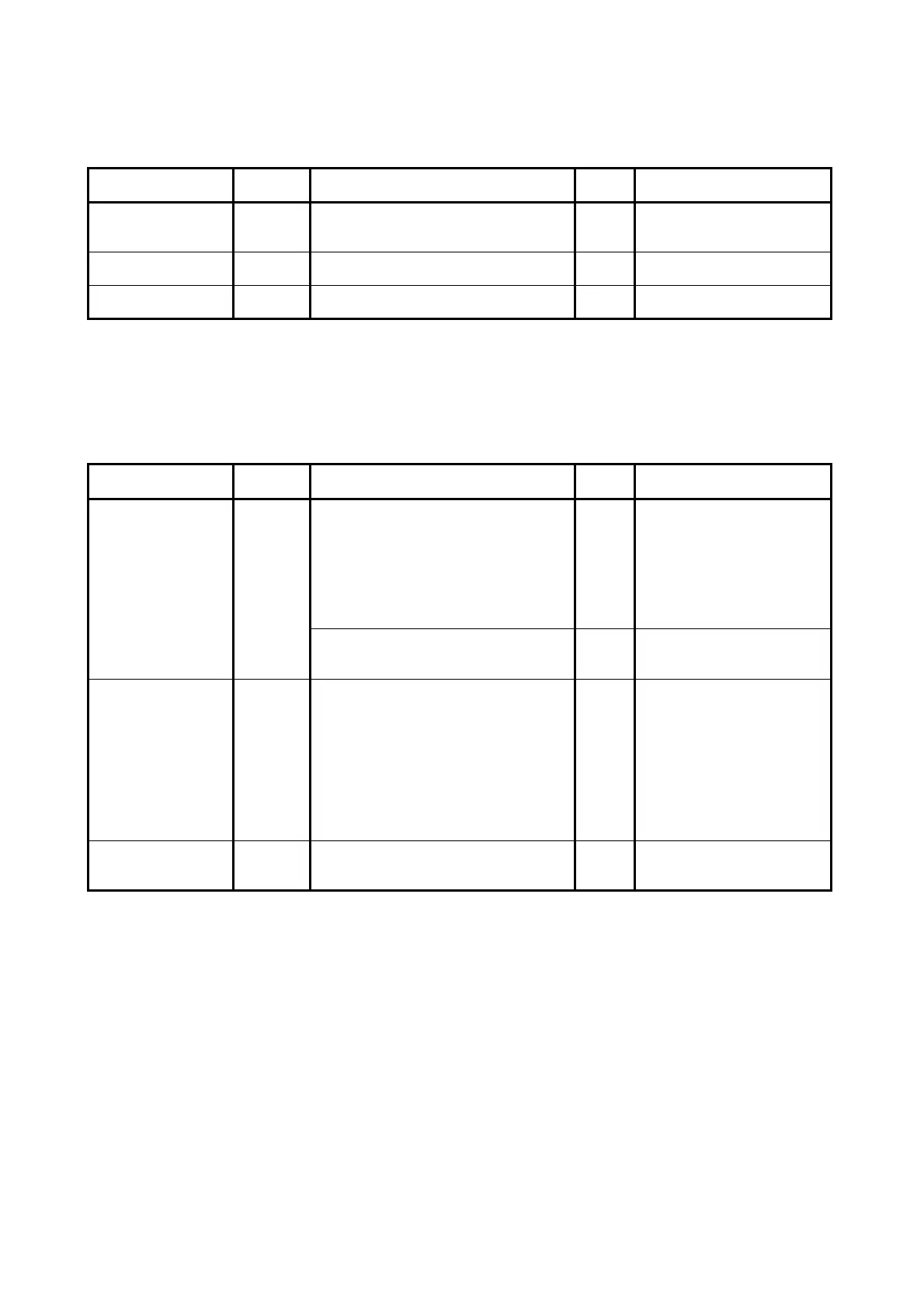

Cause Checking

order

Checking Result Treatment

Setting of Leading

Registration

1 Is the Leading Registration or Leading

Margin properly adjusted in the Service

Mode?

No Adjust it properly.

Feed rollers 2 Have you used the feeding rollers for

very long term?

Yes Replace them.

Registration Clutch 3 Does the Registration Clutch operate

correctly without slipping?

No Replace Registration Clutch.

7. 2. 2.13 Jitter

Check the following matters with the Test Pattern No.1 S(0) and No.7 S(0).

If necessary use other Test Patterns.

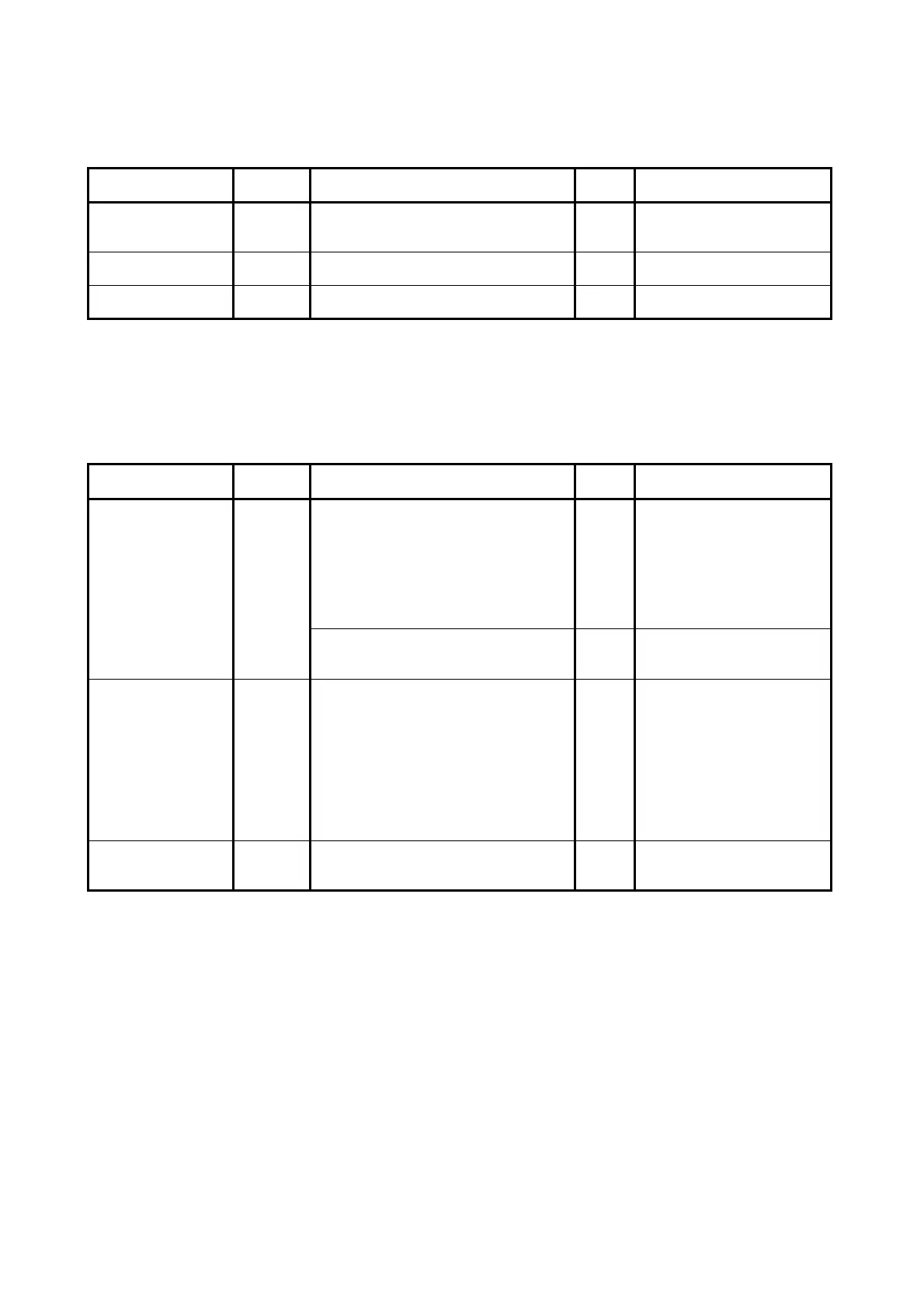

Cause Checking

order

Checking Result Treatment

Photoconductive

Drum and its driving

mechanism

1 Does the jitter appear on the print

constantly keeping about 251mm of

interval?

Yes 1. Check if there is any

damage or foreign

substance on Pulley on

the drum shaft.

2. Check if there is any

foreign substance between

Drum and Counter Rollers

of Developer Unit.

Does the jitter appear on the print

constantly keeping about 3mm of

interval?

Yes Check the engagement of

Pulley Gear on the Drum

with Belt 4.

Developer Unit 2 Does the jitter appear on the print

constantly keeping about a certain

distance of interval listed below?

9.0mm

12.0mm

16.9mm

21.1mm

31.7mm

144.0mm

Yes Replace the Developer Unit

with a new one.

Fuser Unit 3 Does the jitter appear on the print

constantly keeping about 125mm of

interval?

Yes Check for Fuser Drive Gear,

attached foreign substance.

Loading...

Loading...