K117sm8eB

8-135

8. 13. 4 Scanner Adjustment Procedure

It is possible to make the following scanner adjustment with KIP Scanner Utility.

• Shading (calibration)

• Feed Distance (1:1)

• Position (stitching)

These adjustments are very important because they are greatly related with the image quality.

8. 13. 4. 1 Shading (calibration)

[Purpose of Shading (calibration)]

The pixels on the CIS are not same but they have their own characteristic.

This may be a problem because the inputs (density) from those pixels are uneven although they

read the same image (density).

But the Shading compensates the input from each pixel properly to remove the unevenness

among the pixels.

As a result the even level of input can be expected from every pixel after Shading.

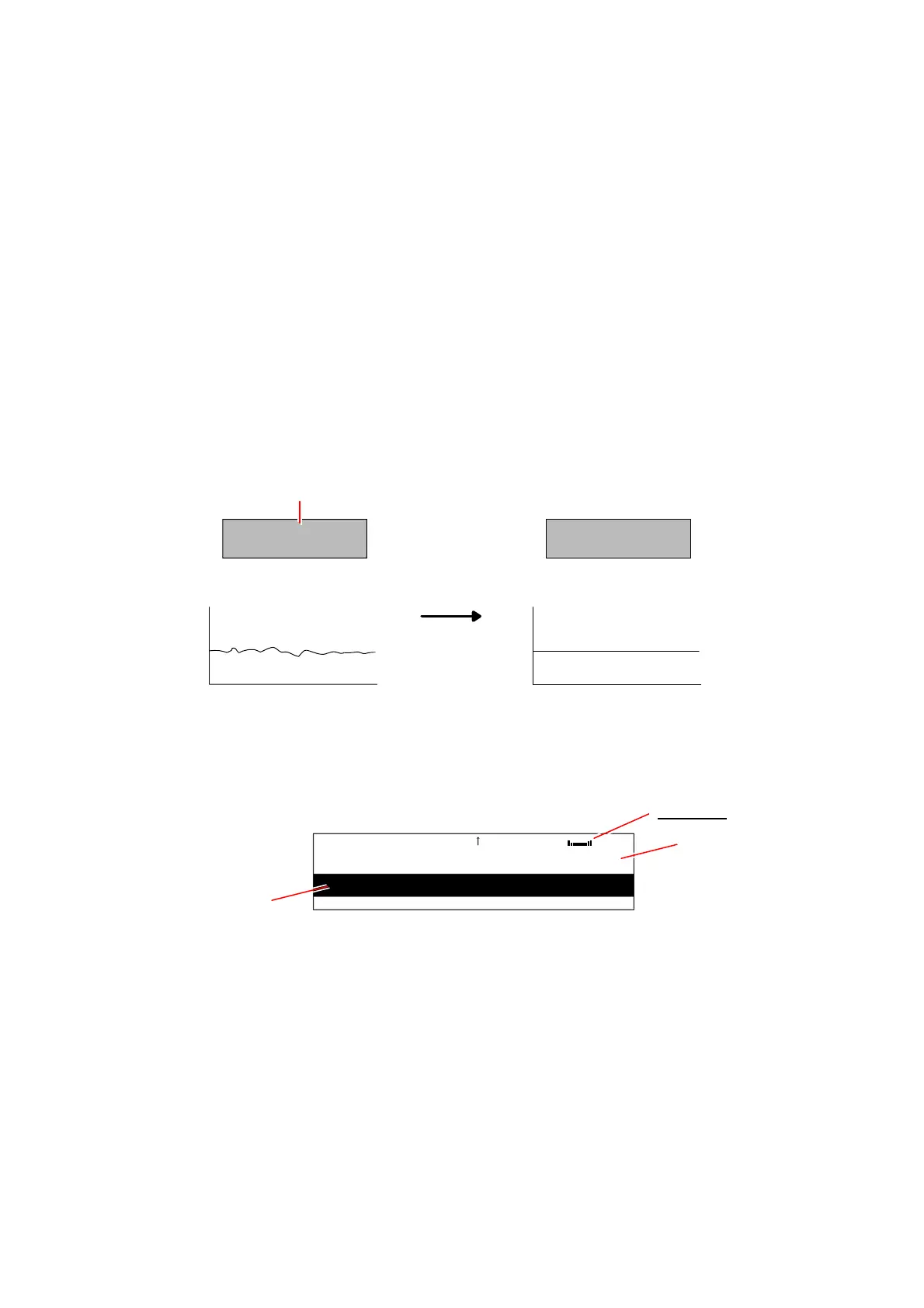

Original (even density)

Dark Dark

Light Light

Before Shading After Shading

(Uneven inputs) (Even inputs)

On Shading adjustment, the pixels on the CIS will be calibrated in the default for R/G/B light

source by using input gaps between black and white on Shading Sheet.

The KIP 700m uses R/G/B light sources not only for color reading but also for monochrome

reading. The scanner unit will be calibrated in monochrome/color at the same time.

[Necessary situation]

Shading is required after replacing;

• CIS

• CIS Board (117)

• Main Board (117)

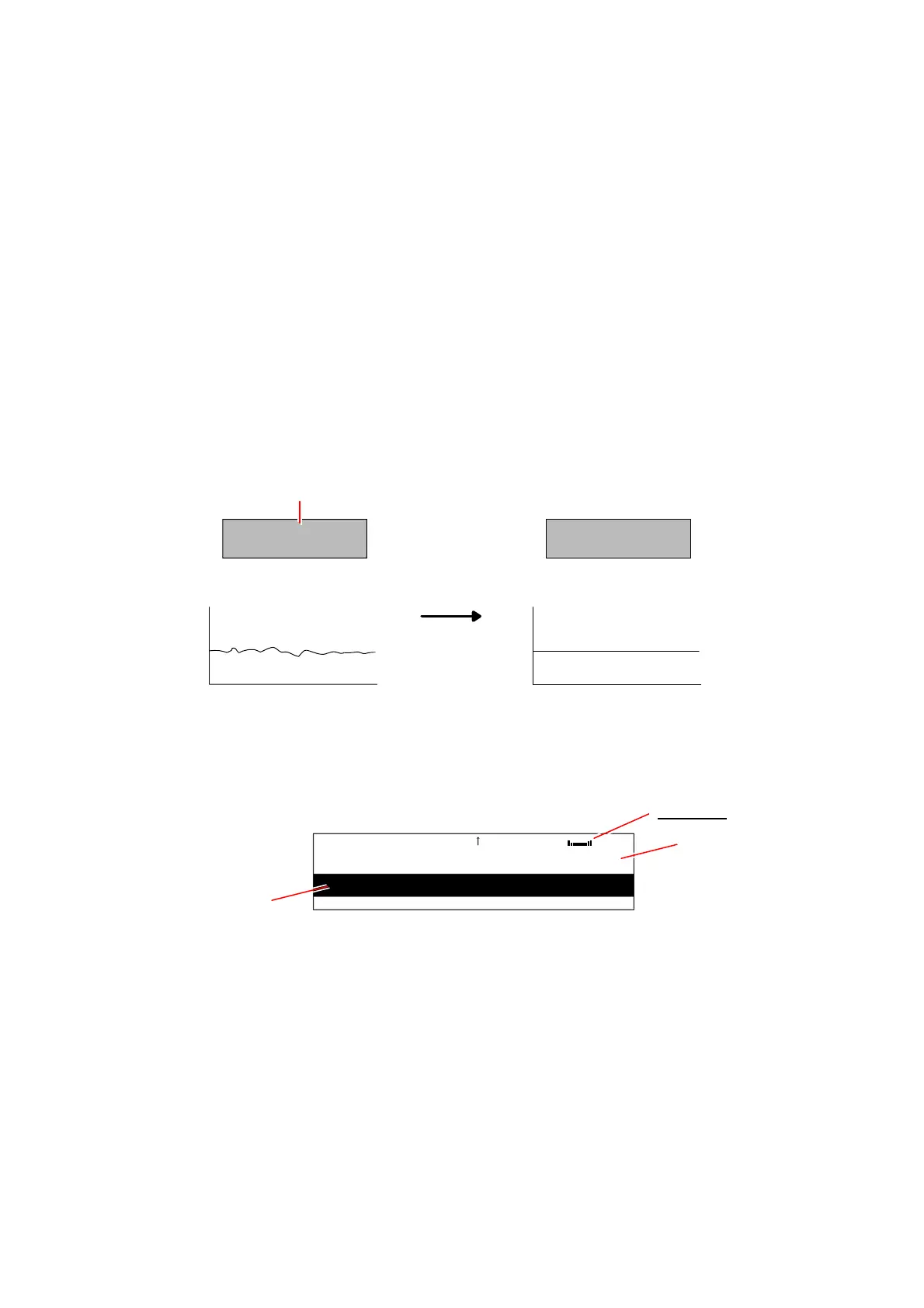

White Area

Black Area

Shading Sheet

Bar Code

Loading...

Loading...