K117sm3e1

3-4

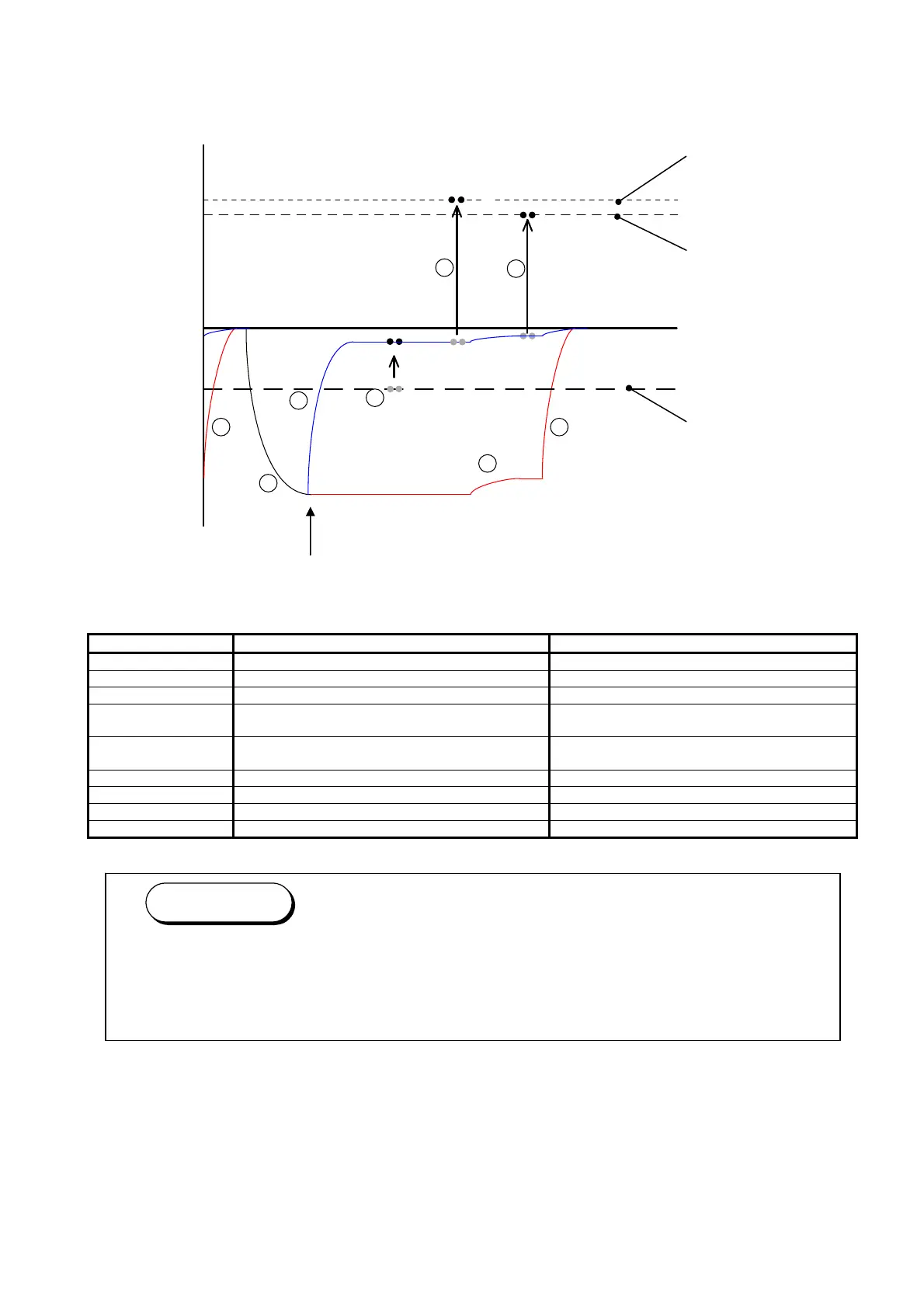

Processes from 1 to 8 are related with the control of the electric potentials.

The following graphic shows the electric potential at each process and the movement of toner.

Surface Potential of Drum

SP1 : For black image / SP2 : For white image

Name of part Voltage (Current) during Print Cycle Voltage during Toner Collection Process

Image Corona Wire -1.3mA +/-0.05mA -

Grid Plate -630V +/-30V -

Developer Roller -230V +/-5V +350V +/-5V

Regulation Roller

(Center)

-80V +/-5V against the Developer Roller Bias -80V +/-5V against the Developer Roller Bias

Regulation Roller

(Both sides)

0V (Connected to the ground) 0V (Connected to the ground)

Toner Supply Roller The same voltage with Developer Roller Bias The same voltage with Developer Roller Bias

Transfer Corona +1.0mA +/-0.05mA -

Separation Corona AC (5.0KV) + DC (-250V +/-5V) -

Cleaning Roller +450V +/-5V -550V +/-5V

0V

-100V

-200V

-300V

-400V

-500V

-600V

-700V

+400V

+300V

+200V

+100V

+500V

2

3

4

5

6

7

1

+600V

SP1

SP2

+700V

1

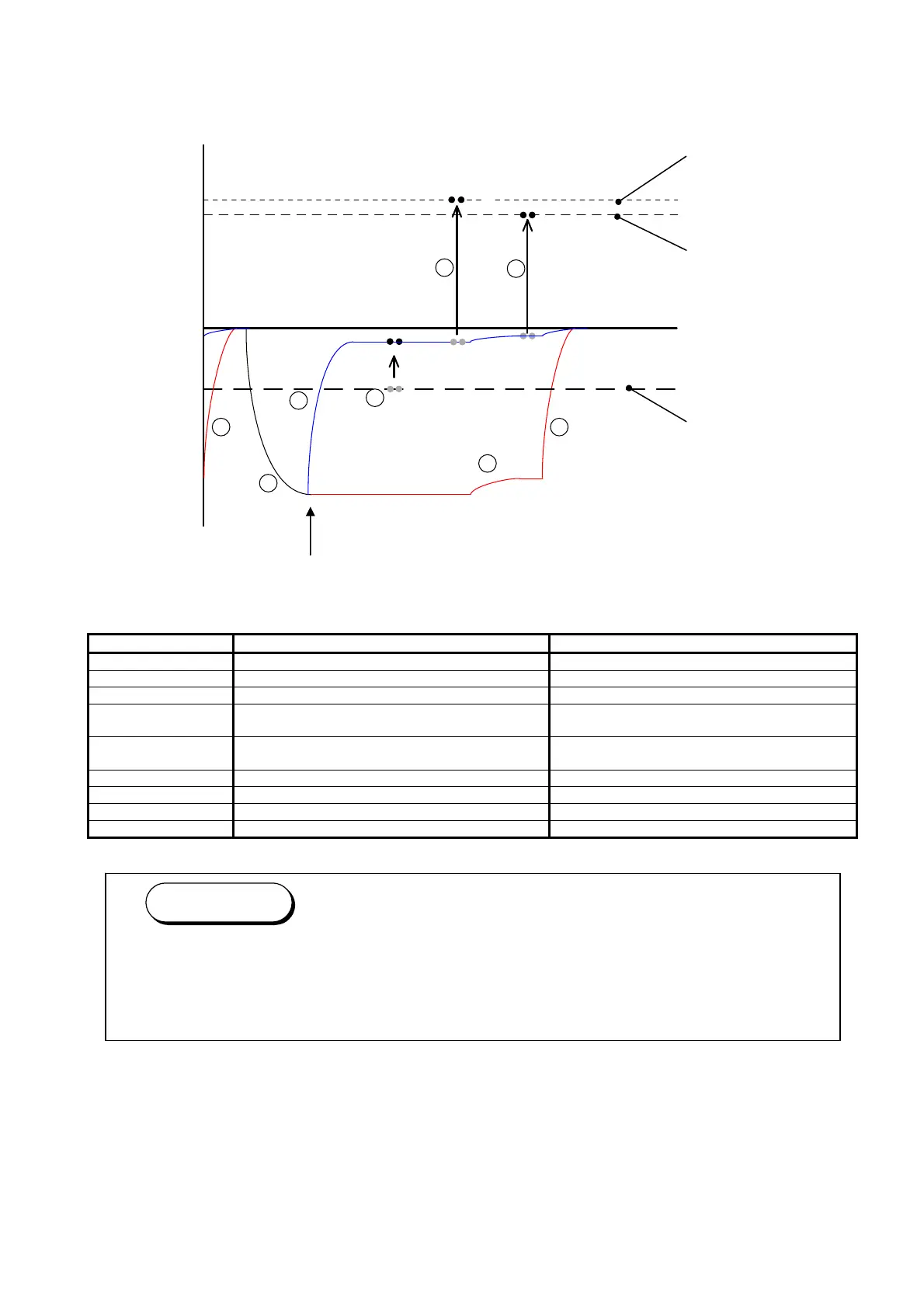

When the printer is going to stop after printing, or when the used Roll Deck is changed with

other one, the KIP 700m will take the “Toner Collection Process” to remove the remained

toner and place back into the Developer Unit.

Refer to [3.1.4 Toner Collection Process].

Reference

Voltage of

Cleaning Roller

Voltage of

Transfer Corona

Voltage of

Developer Roller

Loading...

Loading...