K117sm3e1

3-16

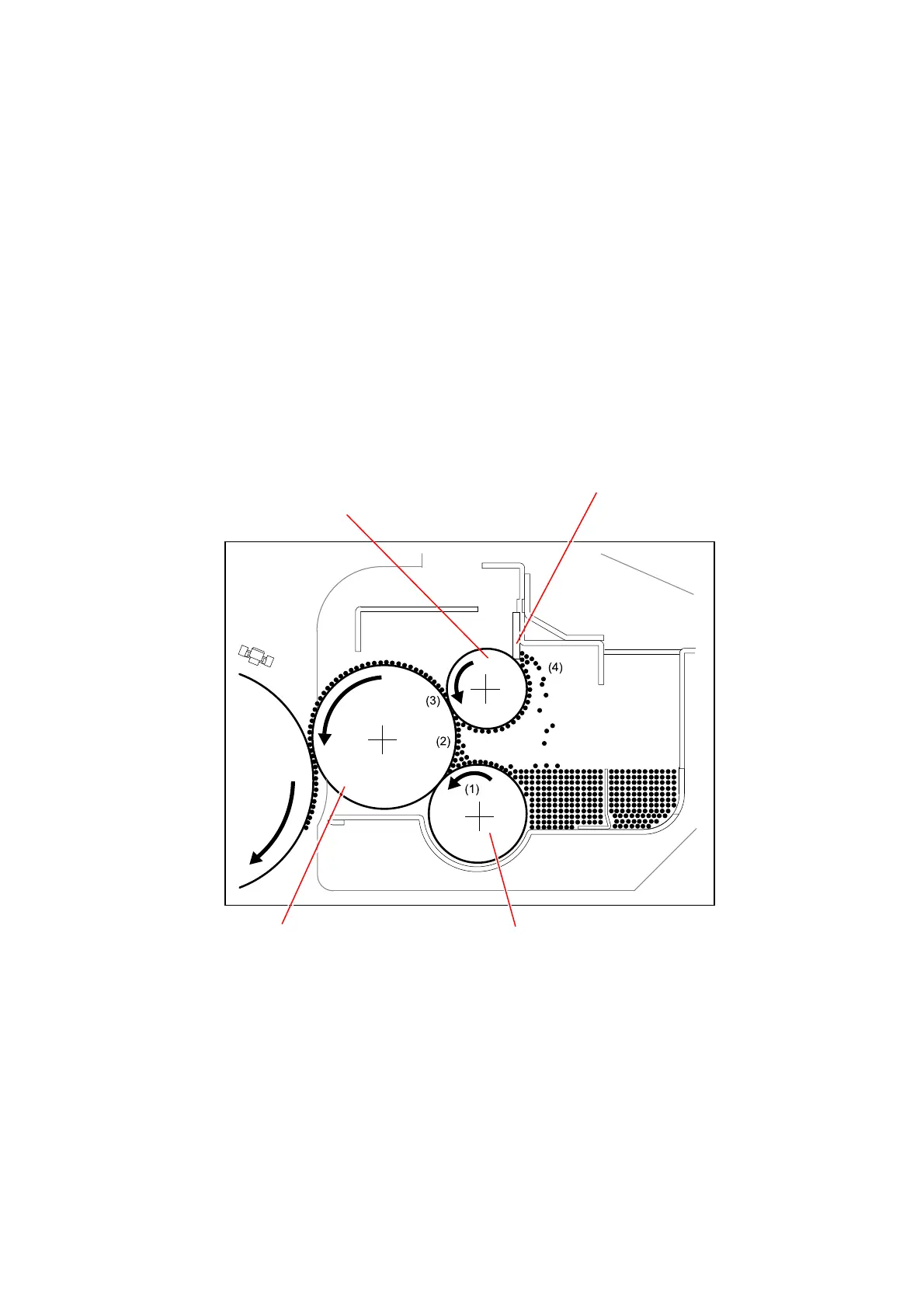

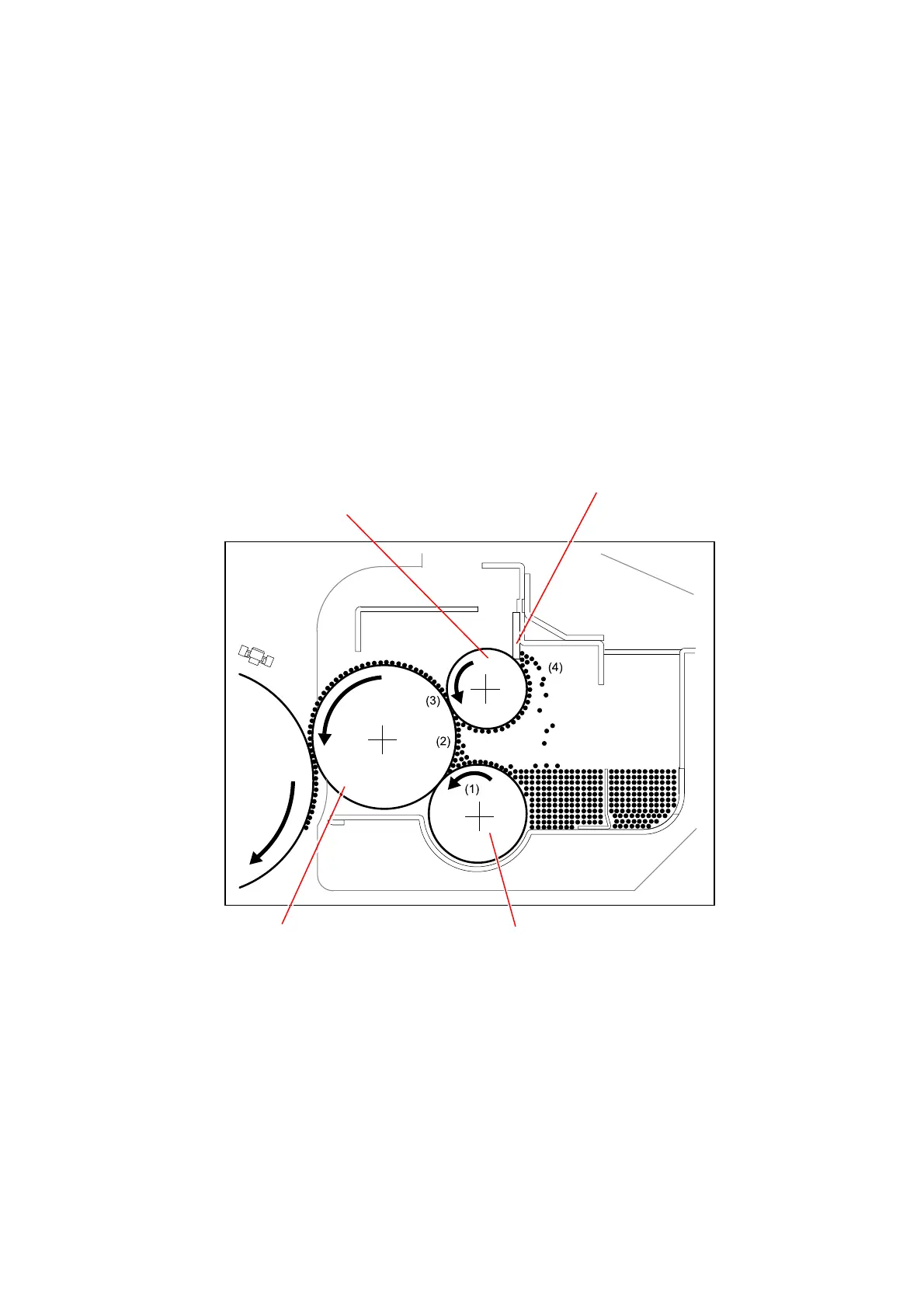

Taking advantage of the difference of potentials among these rollers, the movement of toner is

controlled in the Developer Unit as follows.

1. The Toner Supply Roller carries the toner toward the Developer Roller.

2. When the toner reaches the contact point of these rollers, therefore, it moves onto the

Developer Roller.

Then the Developer Roller carries the toner toward the Regulation Roller.

3. The Regulation Roller is strongly pressed to the Developer Roller by the spring, and these

2 rollers move to the opposite direction each other at the contact point.

Even if the Developer Roller carries more toner than required, the Regulation Roller limits

the amount of toner that can pass through between 2 rollers. So very small amount of toner

can pass through between rollers and the rest is returned back to the inside.

As the voltage of Developer Roller is 80V higher than that of Regulation Roller (Center), the

toner which has passed through between rollers is firmly attracted to the Developer Roller.

Very thin layer of toner is evenly formed on the surface of Developer Roller as a result.

4. Much toner sticks onto the Regulation Roller when it is returned back to the inside.

This toner is scraped off by the Scraper which is contacted to the Regulation Roller.

Regulation Roller : Center Scraper

(-80V against the Developer Roller Bias)

Developer Roller Toner Supply Roller

(-230V against GND) (Same voltage with the Developer Roller)

Loading...

Loading...