215916 473 Revision A

Installing Drive Wheels

Be sure to check the wheel nut torque again once the windrower has begun operation.

CAUTION

Use a lifting device capable of supporting a minimum of 907 kg (2000 lb.) to lift the wheel assembly.

IMPORTANT:

The windrower must be supported off the ground with stands while the drive wheels are being installed. For instructions,

refer to Raising Drive Wheel, page 471.

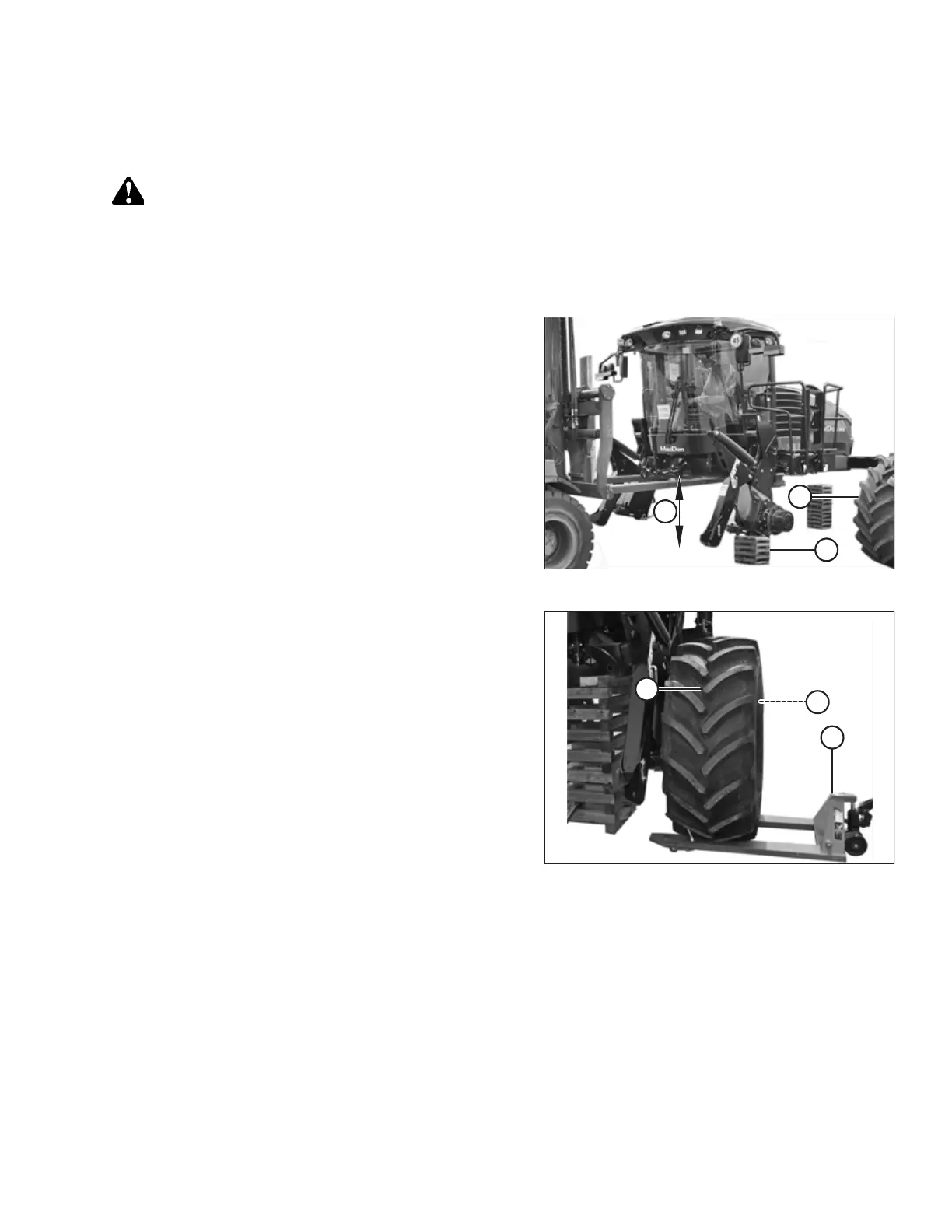

Figure 5.232: Windrower Supports in Place

1. Using a forklift, lift the cab end of the windrower

approximately 130 cm (51 in.) (B) off of the ground, or

enough so that left cab-forward drive wheel assembly (A)

can be positioned as shown. Place stand (C) under the

windrower frame.

2. Clean the mounting surface on the wheel drive and the rim.

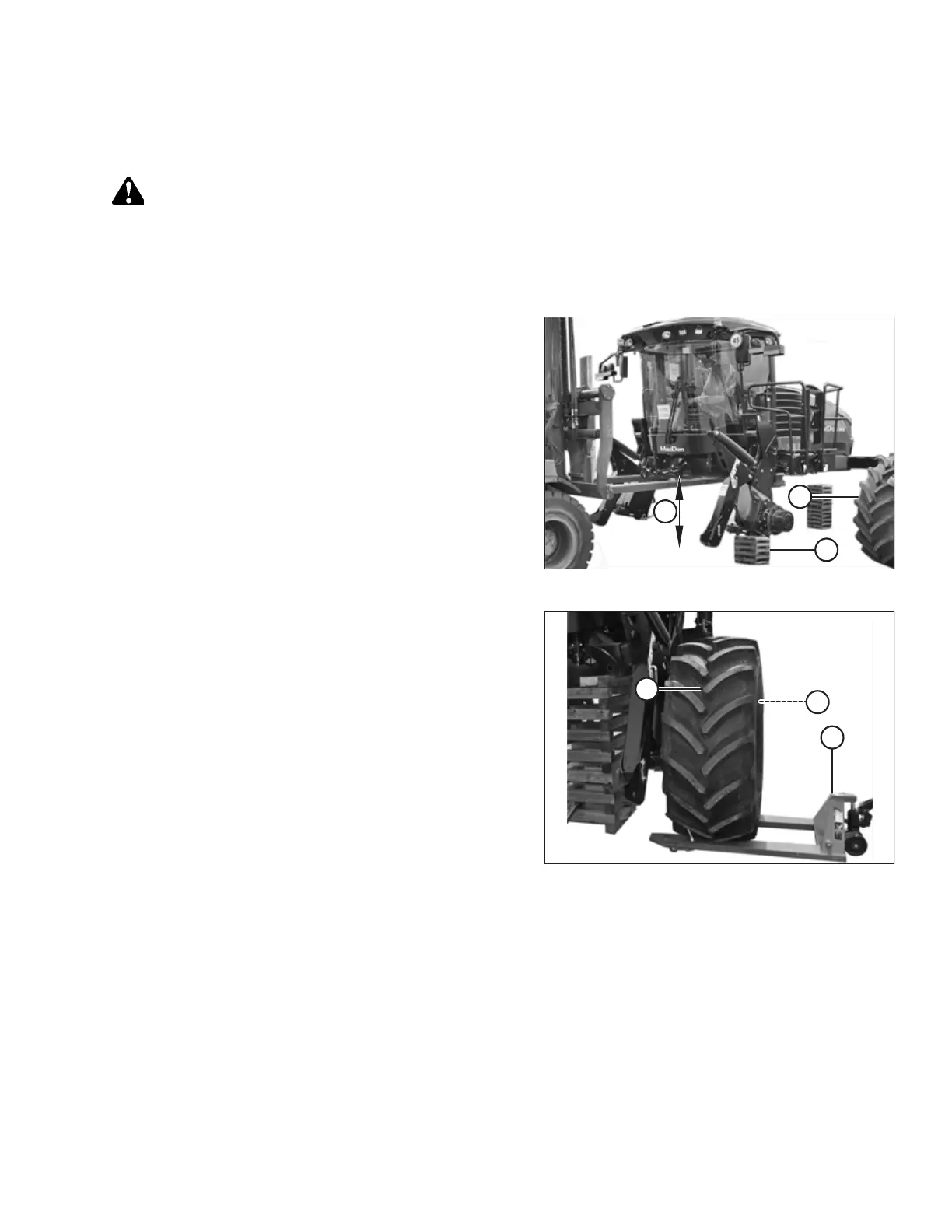

Figure 5.233: Drive Wheel Ready for Installation

3. Position lifting device (A) under the wheel and raise the

wheel slightly.

4. Position the wheel against the wheel drive hub so that air

valve (B) is on the outside while tread (C) points

cab-forward.

NOTE:

For wheels equipped with turf tires (those with a diamond

tread pattern), be sure that the arrow on the sidewall

points cab-forward.

Figure 5.234: Tightening Sequence – 10-Bolt Wheel

5. Align the wheel rim with the studs on the hub. Push the

wheel onto the hub.

6. Install and hand-tighten wheel nuts (A).

IMPORTANT:

To avoid damage to the wheel rims and studs, do NOT use

an impact wrench to tighten the nuts. The stud threads

must be clean and dry. Do NOT apply lubricant or anti-seize

compound to the stud threads. Do NOT overtighten the

wheel nuts.

MAINTENANCE AND SERVICING

Loading...

Loading...