PROGRAMMING GUIDE

SINUS PENTA

233/486

Examples

This section covers some examples for the supervision of pumping systems with the PID control algorithm.

The settings of the parameters being used are given in the tables below: the parameters highlighted in grey have no

effect.

Example 1: Dry Run Detection

For most pumps, especially submersible bore-hole pumps, it must be assured that the pump is stopped in case of dry

run. This is assured by the Dry Run Detection feature. How Does It Work?

Dry run detection is based on power/frequency monitoring. Stop (trip) due to dry run is initiated under the following

conditions:

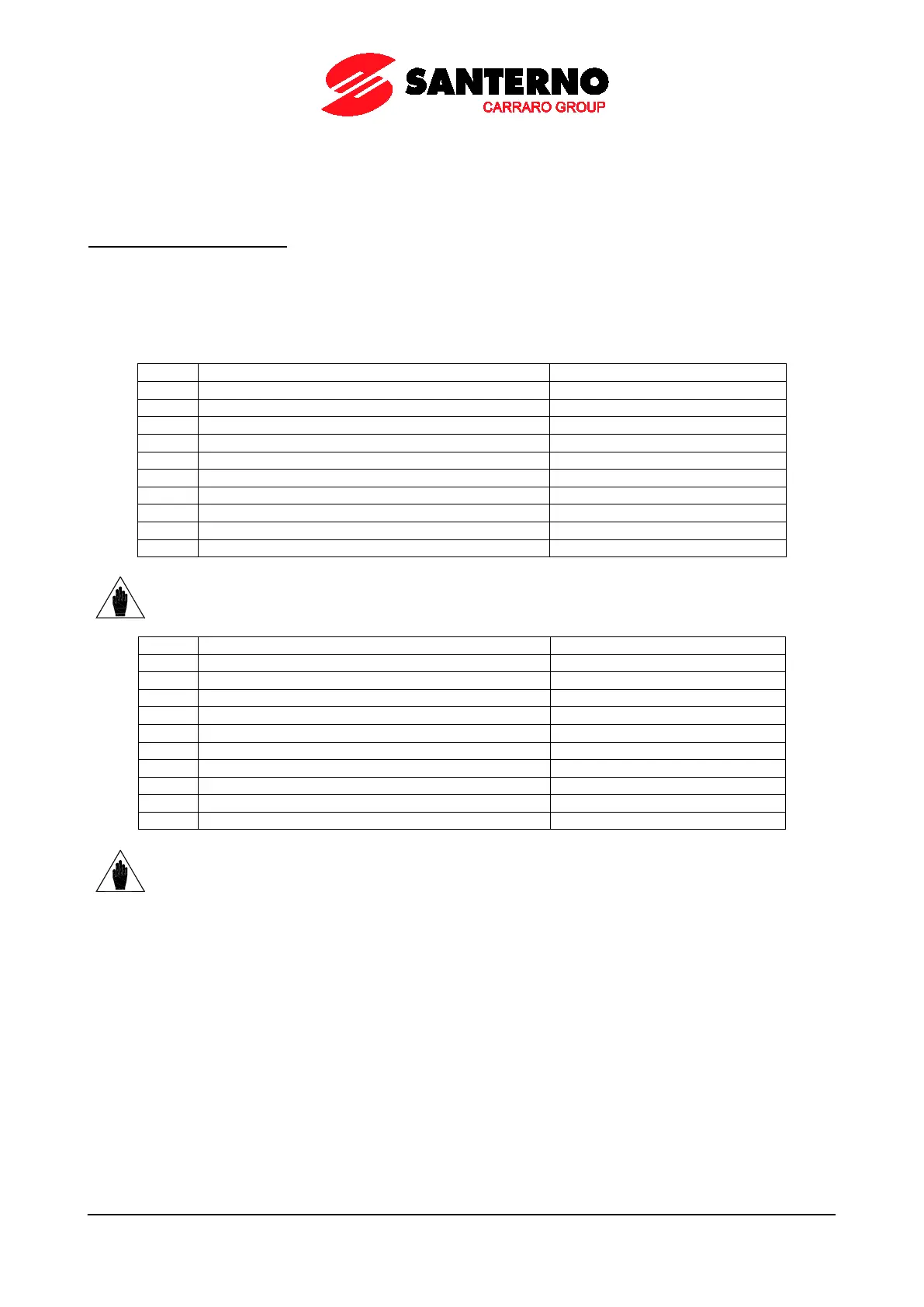

Table 63: MPL parameterization for Dry Run Detection

MPL2: Digital output mode

MPL2: Selecting variable A

MPL2: Selecting variable B

MPL2: Comparing value for Test A

MPL2: Comparing value for Test B

MPL2: Function applied to the result of the 2 tests

MPL2: Selecting variable C

MPL2: Function applied to the result of f(A,B) C

NOTE

It is recommended that a TIMEOUT be entered for Dry Run Detection.

MPL2 output (see TIMERS MENU).

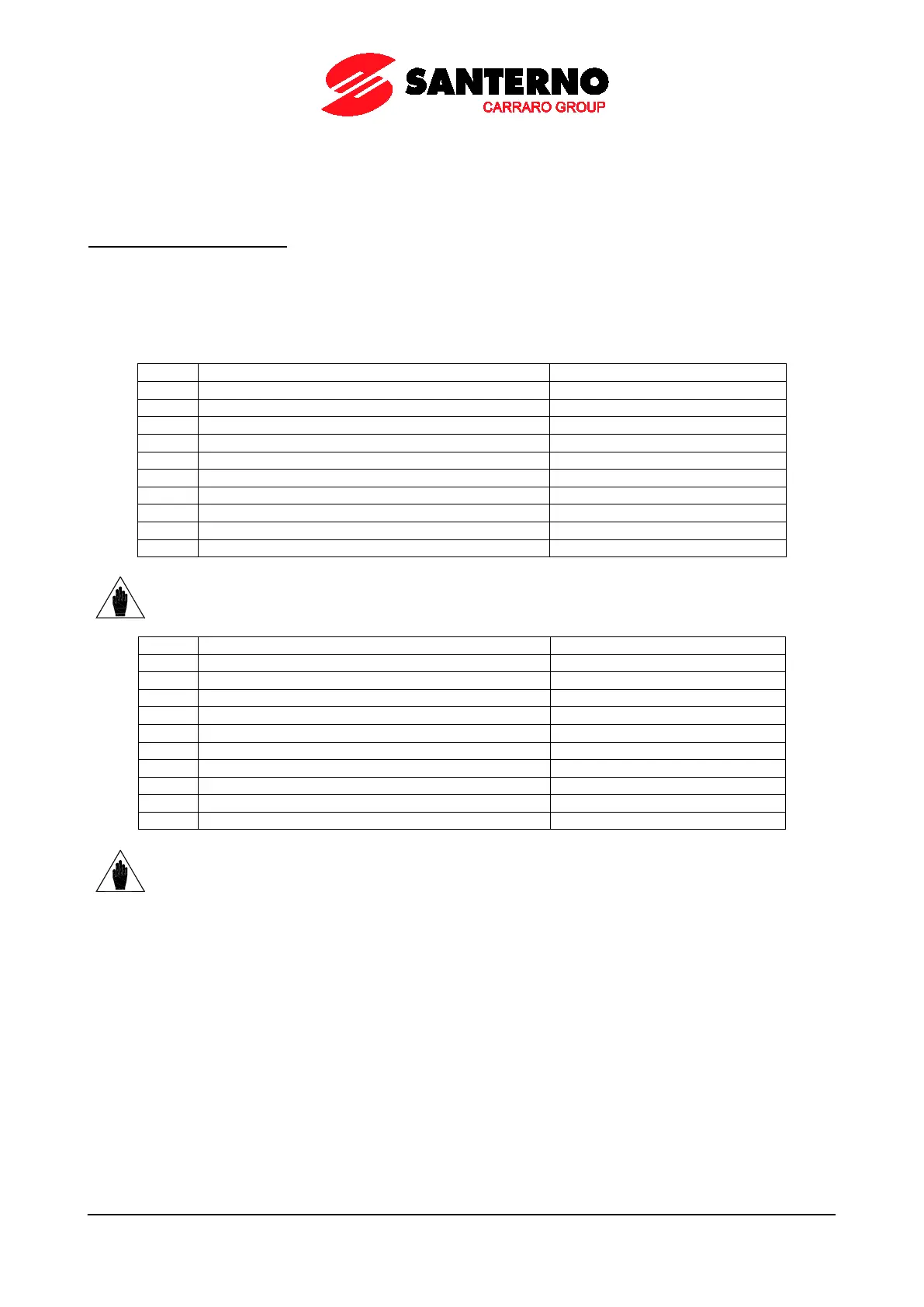

MPL3: Digital output mode

MPL3: Selecting variable A

MPL3: Selecting variable B

MPL3: Comparing value for Test A

MPL3: Comparing value for Test B

MPL3: Function applied to the result of the 2 tests

MPL3: Selecting variable C

MPL3: Function applied to the result of f(A,B) C

NOTE

MPL3 detects when piping is clogged or faulty or when the delivery/pressure sensor is

malfunctioning (e.g. the pump membrane is locked) when the sensor is located downstream

Loading...

Loading...