SINUS PENTA

PROGRAMMING GUIDE

394/486

46. PID CONFIGURATION MENU

46.1. Overview

The Sinus Penta is provided with two separate PID (Proportional, Integral, Derivative) regulators allowing performing

regulation loops such as pressure control, delivery control, etc., with no need to connect external auxiliary devices.

The PID Configuration Menu defines configuration parameters for the two PID regulators.

The configuration parameters for the PID regulator can be modified only when the drive is in stand-by and they set the

following variables: reference sources, feedback sources and type of PID output action.

The programming parameters for the two PID regulators, including coefficients of proportional, integral and derivative

terms, output saturation, etc., are covered in the PID PARAMETERS MENU and the PID2 PARAMETERS MENU.

46.2. Operation and Structure of the PID Regulator

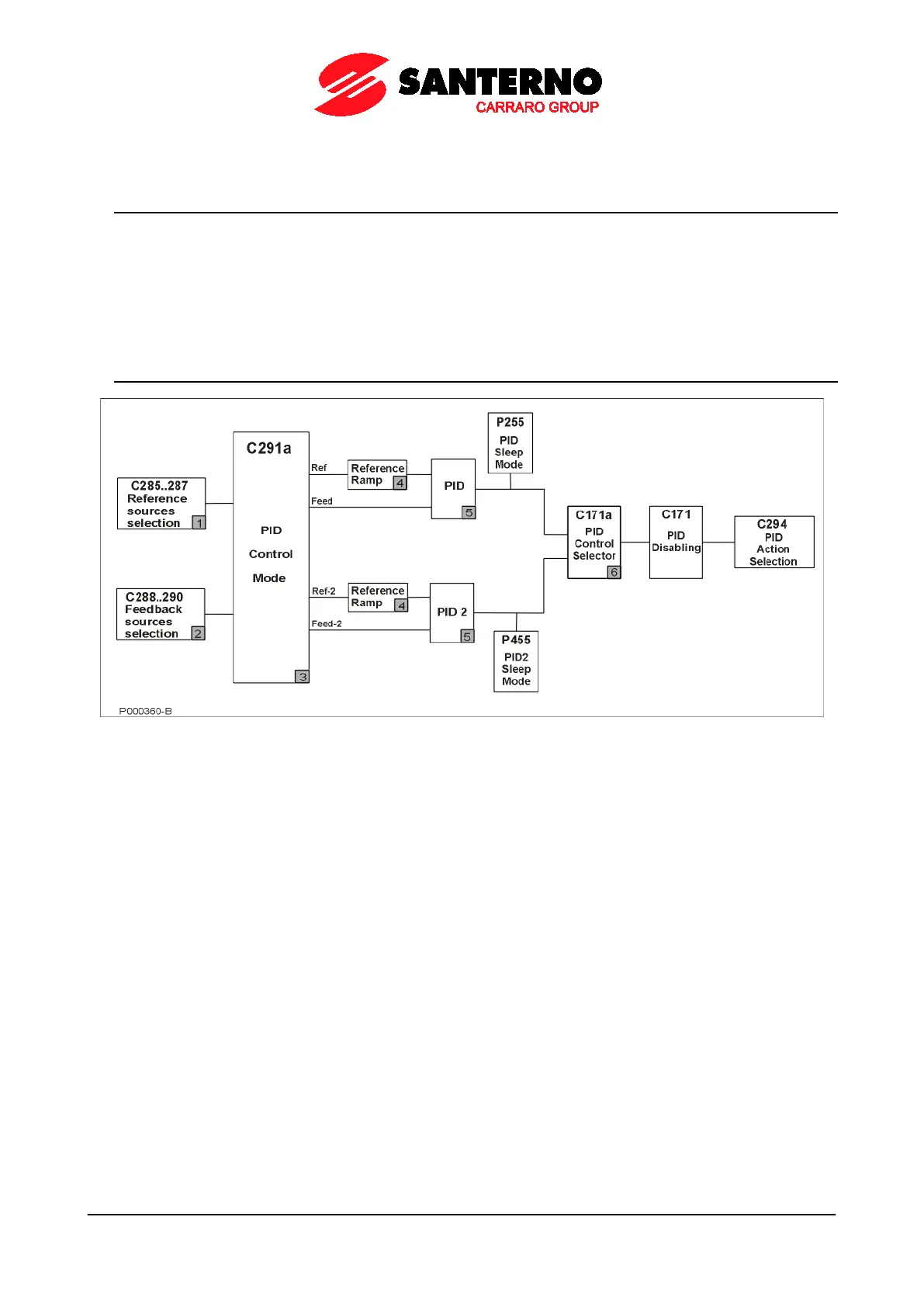

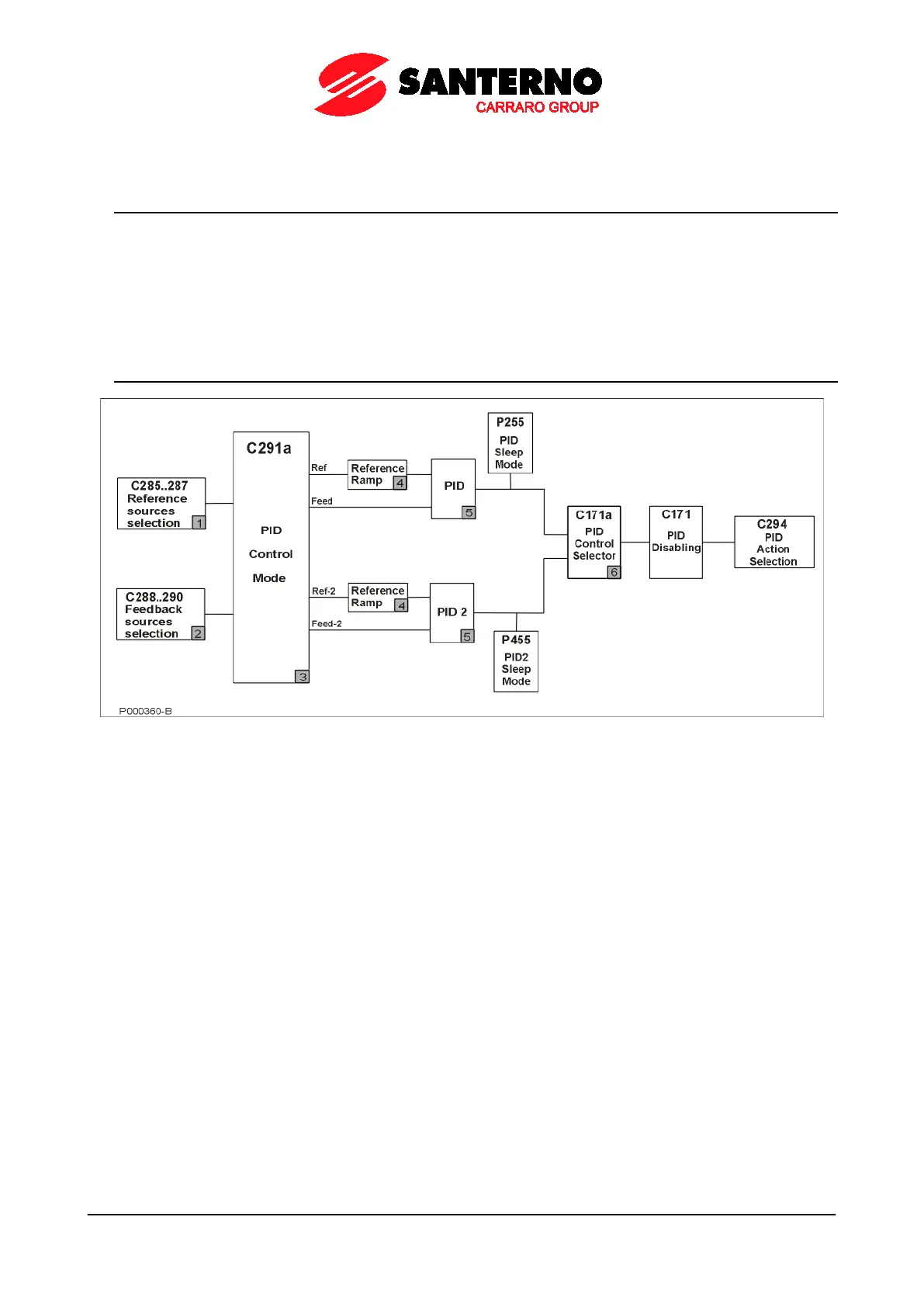

Figure 69: Structure of the PID Regulator

The figure above illustrates the block diagram of the PID regulator. Each block is described below:

Block 1: PID reference sources

Multiple reference sources can be selected at a time (up to 3 reference sources can be selected with parameters C285,

C286, C287).

The resulting reference value depends on the setup in C291a (see block 3).

Dynamic selection is possible between two reference sources using the digital input configured as the source selector

(see C179 and C179b); this parameter has effect only if the Two PIDs mode is activated.

Block 2: PID feedback sources

Multiple feedback sources can be selected at a time (up to 3 feedback sources can be selected with parameters C288,

C289, C290).

The resulting reference value depends on the setup in C291a (see block 3).

Dynamic selection is possible between two feedback sources using the digital input configured as the source selector

(see C179 and C179b); this parameter has effect only if the Two PIDs mode is activated.

Loading...

Loading...