GUIDA ALLA

PROGRAMMAZIONE

SINUS PENTA

359/486

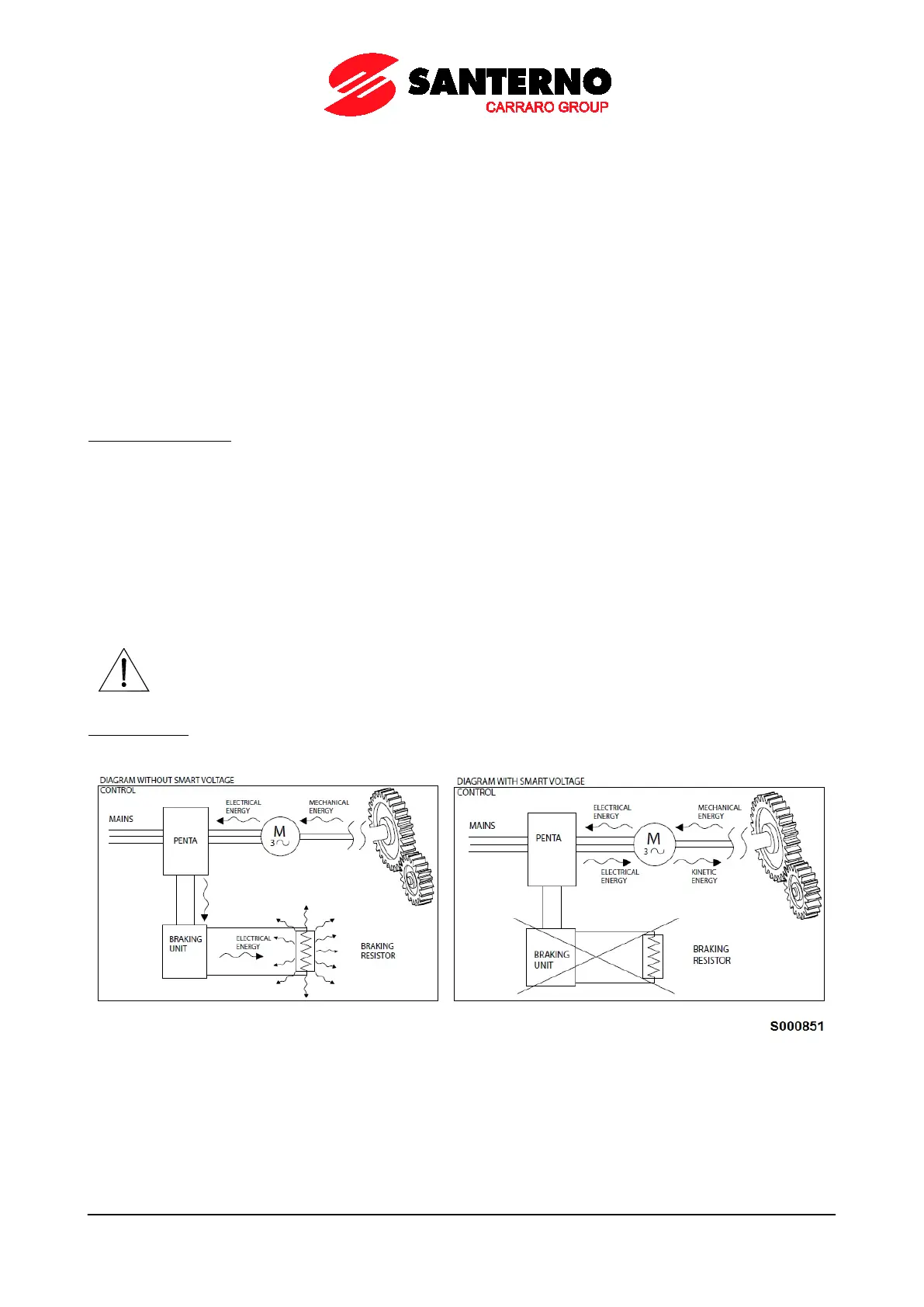

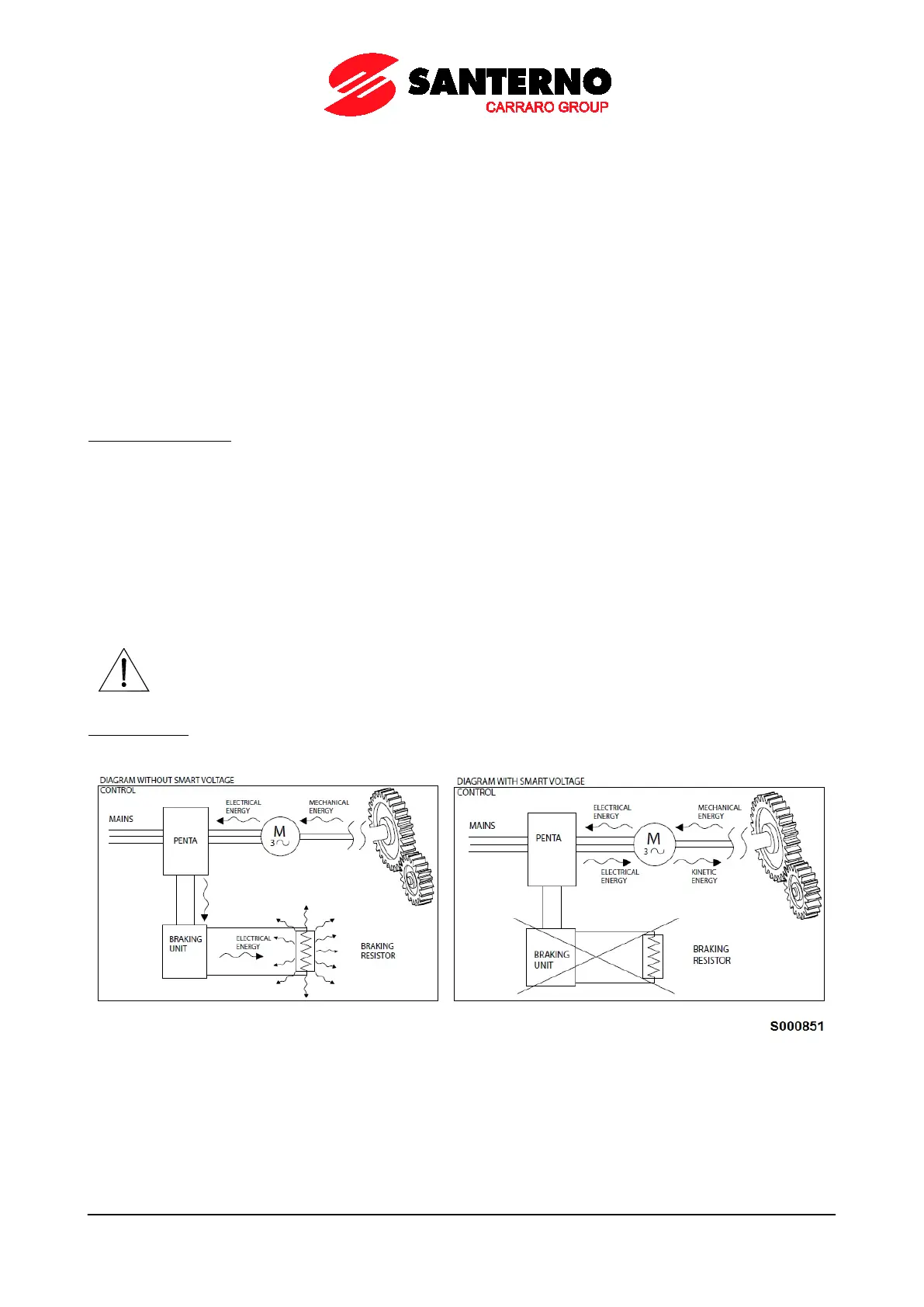

39.1.2. TORQUE LIMIT AND FREQUENCY INCREASE DUE TO

OVERVOLTAGE – SVC (SMART VOLTAGE CONTROL)

When voltage increases due to sudden load variations, the motor operates out of the regeneration range. The

mechanical energy regenerated during the negative torque transient is maintained in the drive-motor unit.

Applications

This control method may be used for applications characterized by:

• sudden variations of the load:

- Olive presses, mills,

- Rock grinders, waste grinders, etc.

• periodic work cycles also including regenerating negative torque areas:

- Pump jacks

- Excentric loads (presses)

- Crank systems

VTC and FOC controls: a special functionality is available, allowing reducing the resisting torque due to DC-bus voltage

increase, in order to prevent the Overvoltage alarm from tripping. A PI regulator is implemented to keep DC voltage

below a preset threshold, thus limiting the maximum value of the resisting torque. In FOC control, this function is

enabled only if C210=0. The regulator may be controlled in VTC control only. Parameters C213a and C213b are the

regulator’s proportional gain and integral gain respectively. Parameter C213c sets the voltage threshold, that equals:

Vth = C213c * Vunlock /100

where Vunlock depends on the drive voltage class and is typically higher than the voltage threshold activating the

braking resistor.

Parameter C213d enables reducing the rotor flux when the regulator activates, thus further limiting the DC voltage

increase.

CAUTION

The reduction of the resisting torque generated by the function above affects the speed

control when the motor accelerates due to external causes. Consequently, it can happen

that the motor accelerates and exceeds the maximum allowable value set in parameter

IFD control only: parameter C213 causes a step increase of the output frequency to limit the DC bus voltage increase

due to an abrupt change (decrease) of the motor load torque.

Figure 56: SVC (Smart Voltage Control)

Loading...

Loading...