PROGRAMMING GUIDE

SINUS PENTA

143/486

21. VTC REGULATORS MENU

21.1. Overview

NOTE

A comprehensive review of the MOTOR CONFIGURATION MENU and the FIRST

STARTUP section is recommended.

NOTE

The VTC Regulators menu may be accessed only if the VTC Control is set up for one of

the connected motors (C010=1 for motor N.1, C053=1 for motor N.2, C096

N.3).

The sensorless VTC control algorithm is based on the same principles as the FOC algorithm, but instead of using the

speed value read from the encoder, it exploits an estimated value of that speed value. Estimation is made possible via a

dedicated status observer.

As is the case of the FOC algorithm, two PI current regulators are available.

The first regulator adjusts the torque current (Iq), whilst the second regulator adjusts the flux current (Id).

Torque current Iq is computed based on the torque setpoint required.

In Slave Mode (torque reference), the torque setpoint is required by the external reference; in Master Mode, the set–

point is given by the speed regulator (see SPEED LOOP AND CURRENT BALANCING MENU) that adjusts the motor

speed of rotation.

Flux current Id is given by the output of the flux regulator, that keeps the motor fluxing correct.

The VTC Regulators menu includes the parameters of the current PI regulators and flux regulators for the VTC Control.

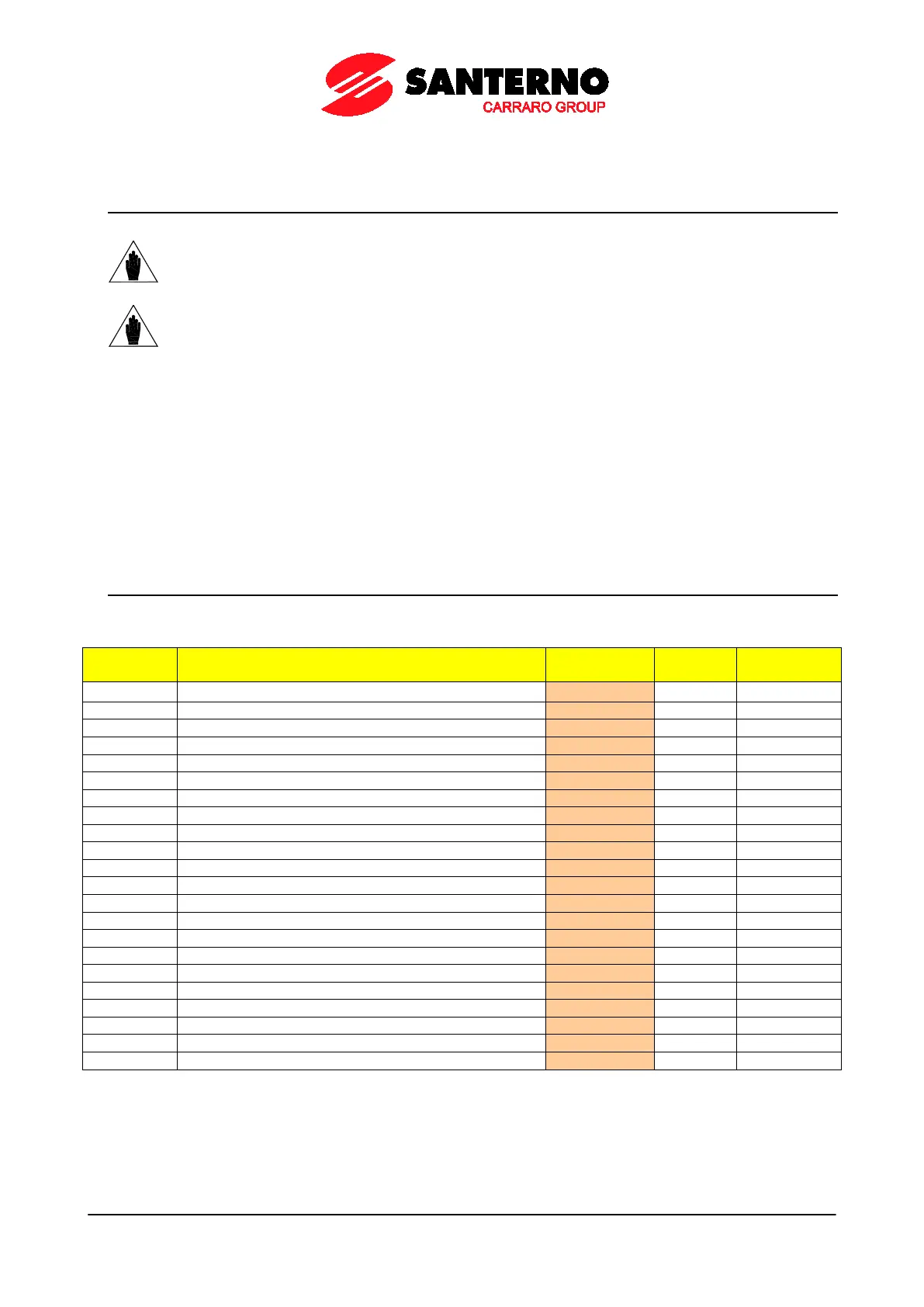

21.2. List of Parameters P175h1 to P175w

Table 35: List of Parameters P175a1 to P175w

Parameter FUNCTION User Level

Low-Frequency Flux Increment Percentage for Motor 1

Minimum Frequency for Motor 1 Flux Increment

Maximum Frequency for Motor 1 Flux Increment

Proportional Gain of Motor 1 Current Controller

Integral Time of Motor 1 Current Controller

Low-Frequency Flux Increment Percentage for Motor 2

Minimum Frequency for Motor 2 Flux Increment

Maximum Frequency for Motor 2 Flux Increment

Proportional Gain of Motor 2 Current Controller

Integral Time of Motor 2 Current Controller

Low-Frequency Flux Increment Percentage for Motor 3

Minimum Frequency for Motor 3 Flux Increment

Maximum Frequency for Motor 3 Flux Increment

Proportional Gain of Motor 3 Current Controller

Integral Time of Motor 3 Current Controller

Current Distortion Threshold

Current Distortion Compensation

Current Distortion Compensation Allocation

Filter Time Constant of Flux Rate Limiter

Type of Control at Stop with Start Open

Loading...

Loading...