M5: Measurement

7.5 Setting zeros, workpiece measuring and tool measuring

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

455

Setpoints

The resultant frame is calculated so that the measurement complies with the setpoints

specified by the user.

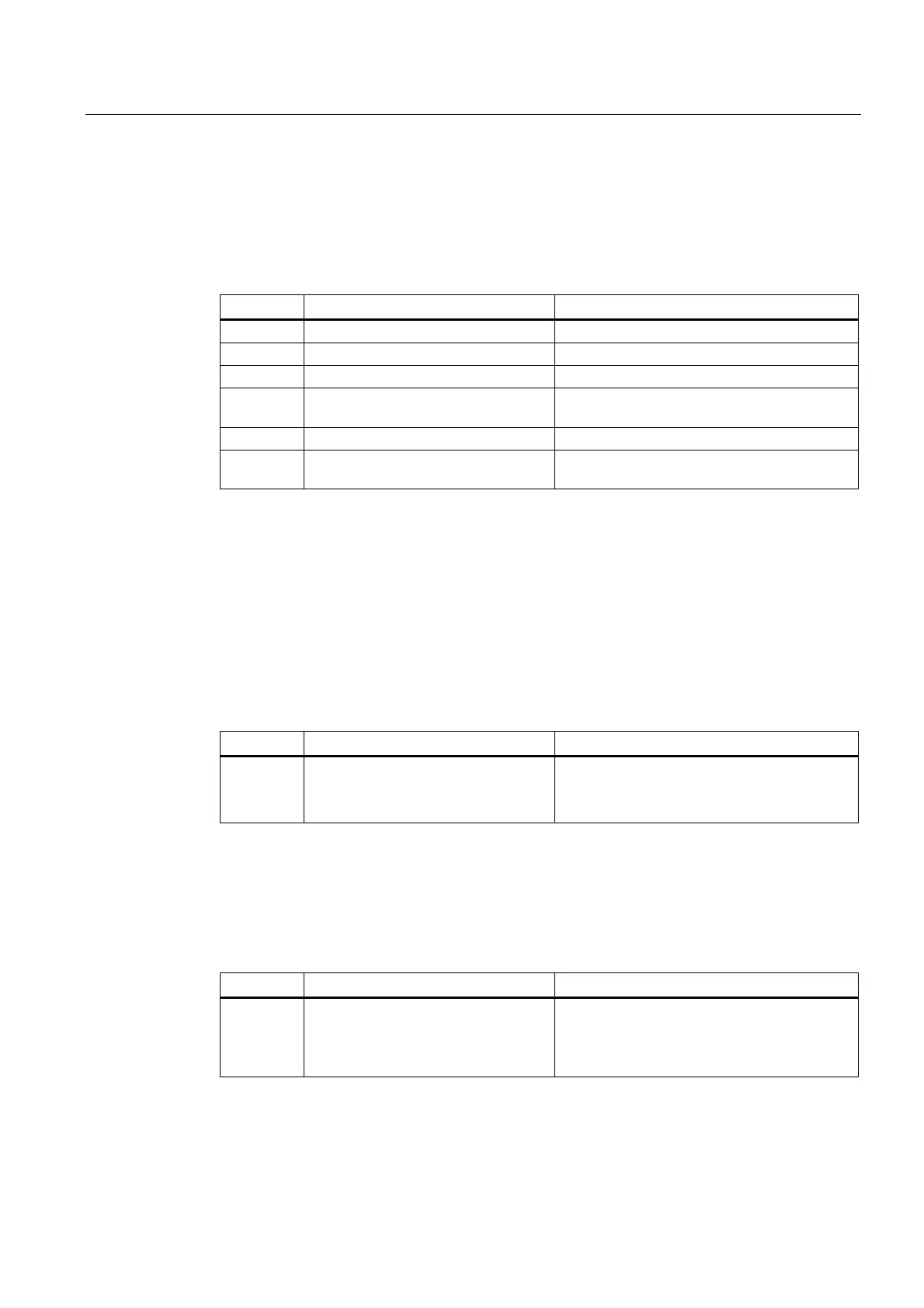

Table 7- 3 Input values for the user setpoint values

Type System variable Meaning

REAL $AA_MEAS_SETPOINT[ax] Setpoint position of an axis

REAL $AA_MEAS_SETANGLE[ax] Setpoint angle of an axis

INT $AA_MEAS_SP_VALID[ax] 1: Setpoint position of axis is valid / 0: Invalid

REAL $AC_MEAS_WP_SETANGLE Rated workpiece position angle α: -90 < α <

180

REAL $AC_MEAS_CORNER_SETANGLE Setpoint cutting angle φ of corner: 0 < φ < 180

INT $AC_MEAS_DIR_APPROACH *) Approach direction:

0: +x, 1: -x, 2: +y, 3: -y, 4: +z, 5: -z

*) The approach direction is required only for the edge, groove, web and tool measurement.

The following measuring points are irrelevant and not evaluated:

● On inputting the setpoint workpiece position angle α: of the 2nd measuring point.

● When inputting the setpoint angle of intersection φ: at the 4th measuring point.

Plane separation

Plane separation for defining the tool orientation. The active level is used for all calculations

if no level is specified.

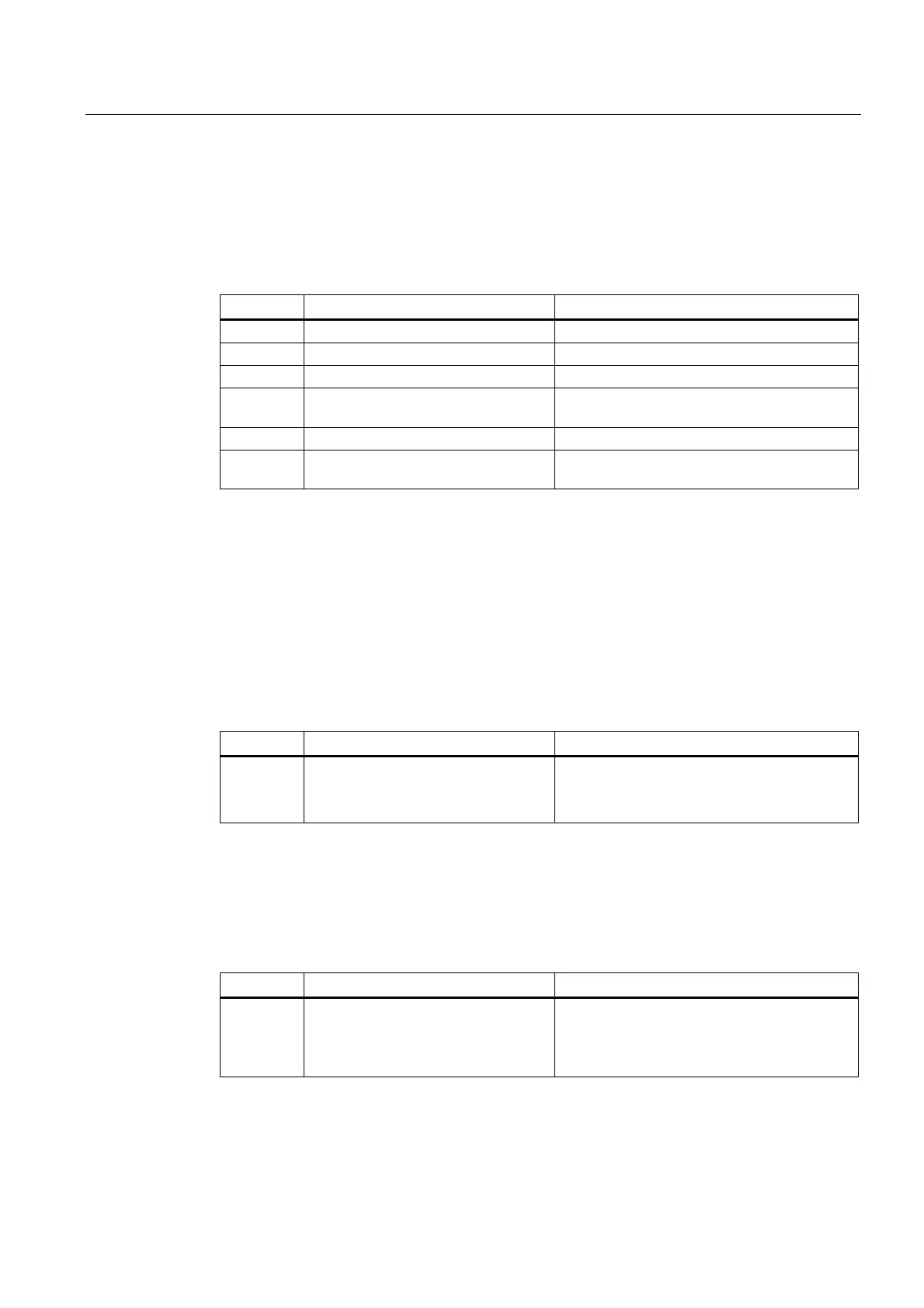

Type System variable Values

INT $AC_MEAS_ACT_PLANE 0: G17 working plane x/y infeed direction z

1: G18 working plane z/x infeed direction y

2: G19 working plane y/z infeed direction x

Translational offsets

When measuring workpieces, translational offsets can be entered in the fine offset

component of the selected frame. Variable $AC_MEAS_FINE_TRANS is used for this

purpose.

Type System variable Values

INT $AC_MEAS_FINE_TRANS 0: Translational compensation is entered in the

coarse offset.

1: Translational compensation is entered in the

fine offset.

Loading...

Loading...