CARE AND MAINTENANCE 7

MHL360 E 7.63

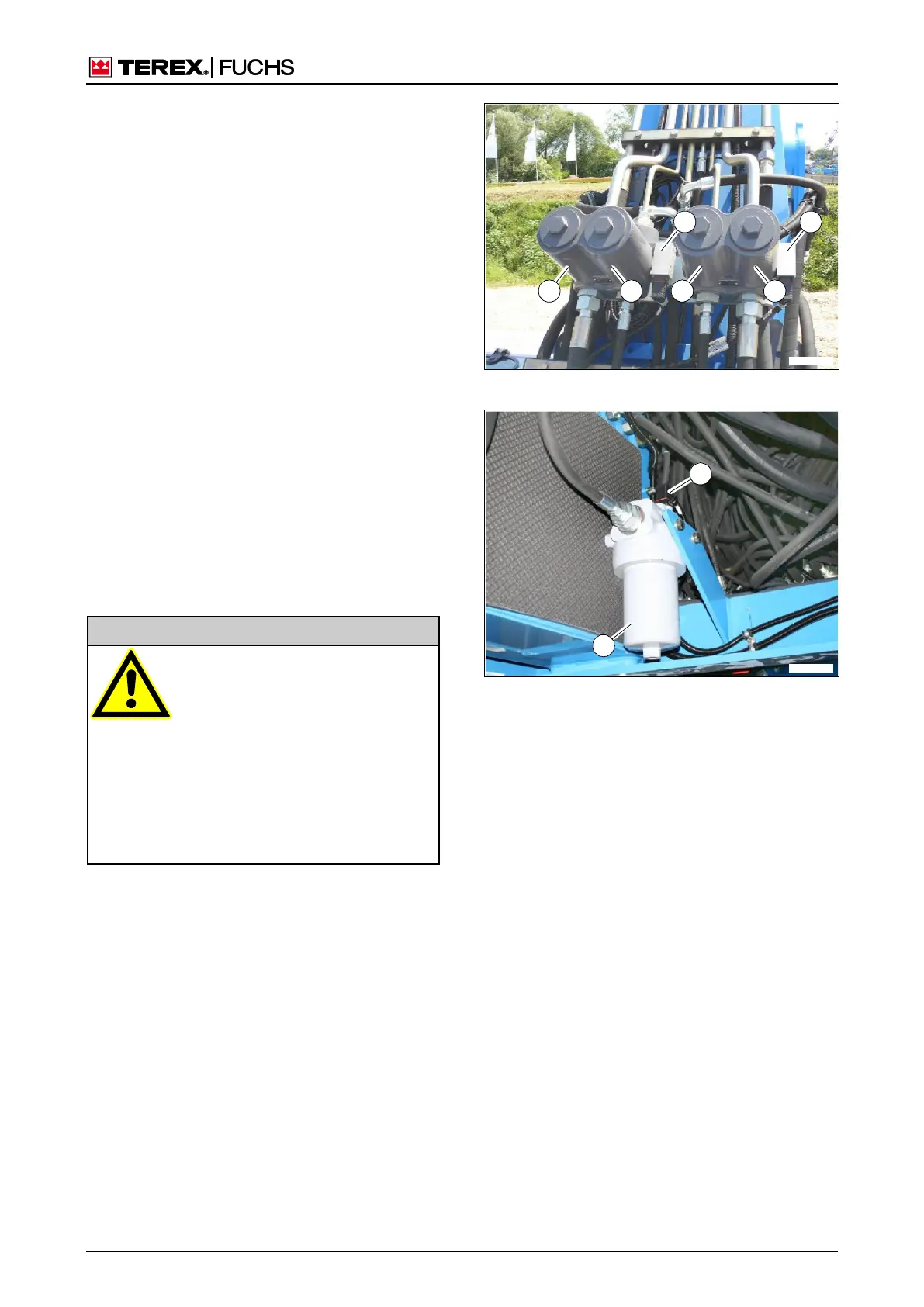

7.7.14.5 Oil filter for grab (optional)

The clogging indicator (315/2) signals an early

filter maintenance with the flow resistance is

too high.

Cleaning and replacing filter elements

►

Release the hydraulic pressure.

►

Unscrew the cover (315/1), remove the

filter element and clean the housing.

►

Fit a new filter element and new seal.

When doing this, oil the threads, sealing

surfaces on the cover and housing, as well

as the seals with hydraulic oil.

►

Screw in the cover. Tightening torque:

50±10 Nm.

► Check the filter for leaks.

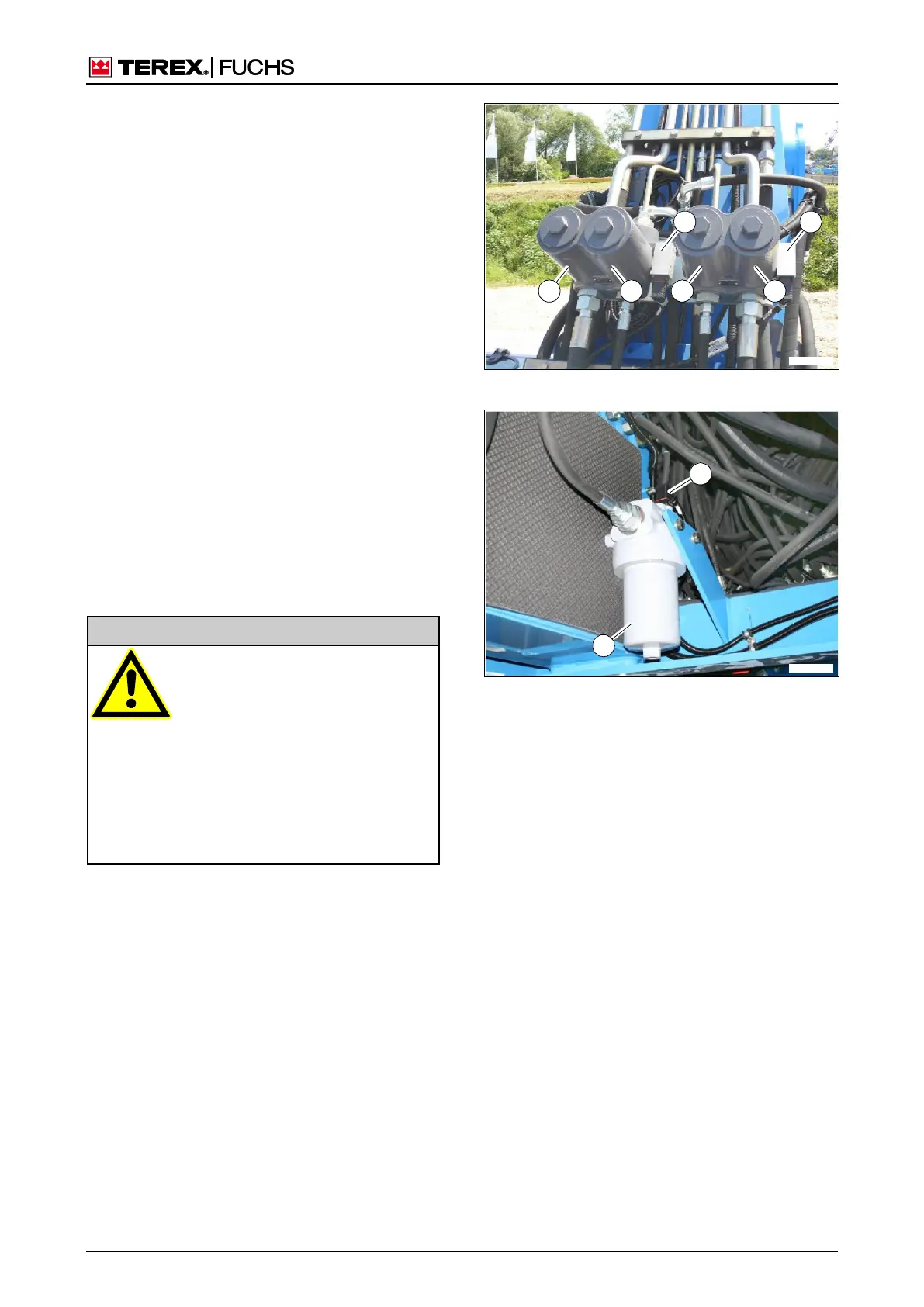

7.7.14.6 Oil filter in the slewing circuit

The contamination indicator (316/2) signals

the need for early filter maintenance when the

flow resistance is too high.

Cleaning and replacing filter elements

Danger of injury due to hydraulic

oil spray

Closed slewing circuit with pressure

filter. Depressurization due to inter-

nal leak!

• Before opening the filter, test the

slewing circuit with a pressure

gauge to check there is no pres-

sure.

In an emergency: Administer first

aid, seek treatment from a doctor

►

Carefully unscrew the cover (316/1), re-

move the filter element and clean the hous-

ing.

►

Fit a new filter element and new seal.

When doing this, oil the threads, sealing

surfaces on the cover and housing, as well

as the seals with hydraulic oil.

►

Screw in the cover. Tightening torque:

40+10 Nm

►

Check the filter for leaks.

Fig. 315 Oil filter grab cylinder

Fig. 316 Oil filter in the slewing circuit

Loading...

Loading...