Variomat Touch — 09.09.2022-Rev. C

English —

22b FB2b --- ---

23 NC

Group message (potential free)

Max. 230 V, 2 A

On-site 24 COM

25 NO

27 M1

Flat plug for supply, pump 1

Factory-

provided

31 M2

Flat plug for supply, pump 2

Factory-

provided

35 +18 V (blue)

Analogue input, LIS level

measurement

at the primary vessel

Cable:

factory-

provided;

Sensor plug:

on-site

36 GND

37 AE (brown)

38 PE (shield)

39 +18 V (blue)

Analogue input, "PIS" pressure

measuring

at the primary vessel

On-site,

optional

40 GND

41 AE (brown)

42 PE (shield)

43 +24 V

Digital inputs

On-site,

optional

44 E1 E1: Contact water meter

Factory-

provided

45 E2 E2: Low water switch ---

PV 2 overflow valve (motor ball

valve), only in VS 2-2

Factory-

provided

52 +24 V (supply)

53

0 – 10 V

(correcting

variable)

54

0 – 10 V

(feedback)

55 GND

PV 1 overflow valve (motor ball

valve)

Factory-

provided

56 +24 V (supply)

57

0 – 10 V

(correcting

variable)

58

0 – 10 V

(feedback)

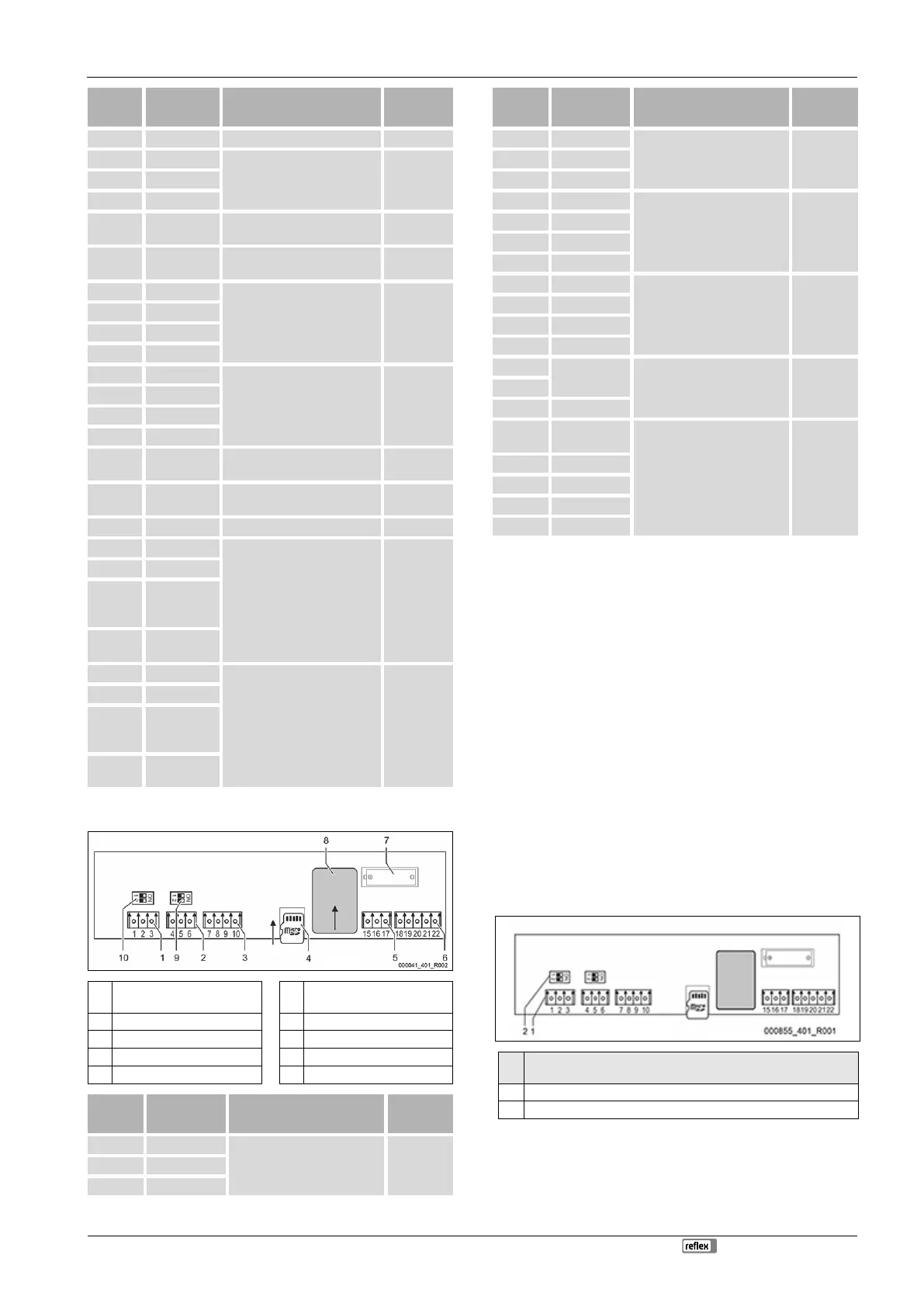

7.5.3 Terminal plan, operating unit

1 RS-485 interface 6

Analogue outputs for Pressure

and Level

2 RS-485 interface 7 Battery compartment

3 I/O interface 8 Anybus module slot

4 Micro-SD card 9 DIP switch 2

5 10 V supply 10 DIP switch 1

1 A

RS-485 interface

S1 networking

On-site 2 B

3 GND S1

4 A

RS-485 interface

S2 modules: Expansion or

communication module

On-site 5 B

6 GND S2

7 +5 V

I/O interface: Interface to the

main board

Factory

8 R × D

9 T × D

10 GND IO1

11 ---

--- ---

12 ---

13 ---

14 ---

15

10 V~

10 V supply Factory 16

18

Y2PE

(shielding)

Analogue outputs: Pressure and

Level

Standard 4 – 20 mA

On-site

19 Pressure

20 GNDA

21 Level

22 GNDA

7.5.4 RS-485 interface

Use the S1 and S2 RS-485 interfaces to retrieve all controller data and to enable

the communication with control centres or other devices.

• S1 interface

– A maximum 10 devices can be used in a master-slave linked circuit

via the this interface.

• S2 interface

– "PIS" pressure and "LIS" level.

– Operating modes of the "PU" pumps.

– Operating states of the motorised ball valve/solenoid valve.

– Values of the "FQIRA +" contact water meter.

– All messages.

– All entries in the fault memory.

The following bus modules form part of the optional accessories available for

interface communication.

Note!

If required, please contact the Reflex Customer Service for the protocol

of the RS

-

485 interface, details of the connections and information about

the accessories offered.

7.5.4.1 Connecting the RS-485 interface

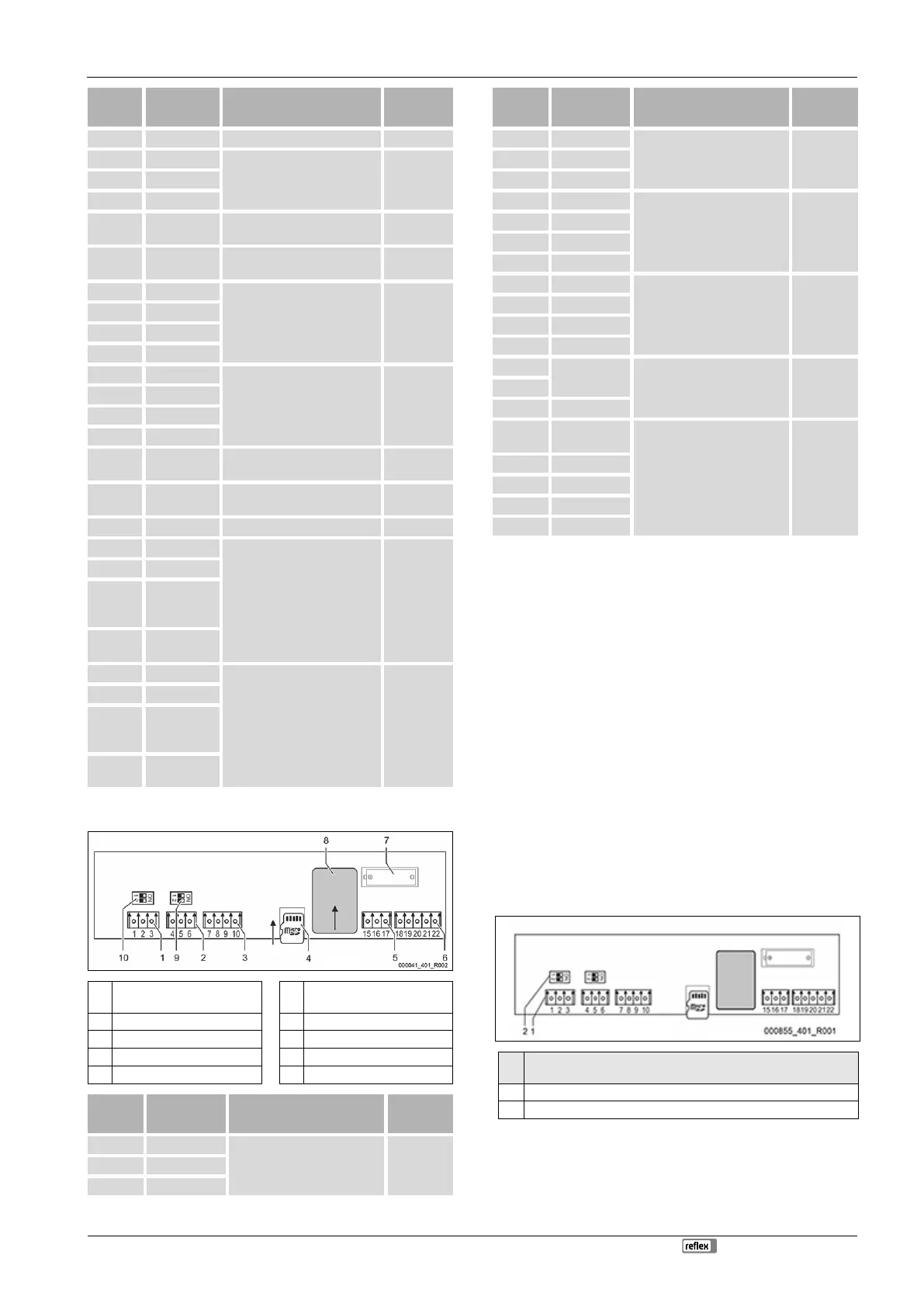

Main board of the Control Touch controller.

1 Connection terminals for RS-485 connection

2 Dip switch 1

Proceed as follows:

1. Use a screened cable to connect the RS-485 interface to the main board.

• S 1

– Terminal 1 (A+)

– Terminal 2(B-)

– Terminal 3(GND)

Loading...

Loading...