PAPER DELIVERY

2-46

C231/C237/C238 SM

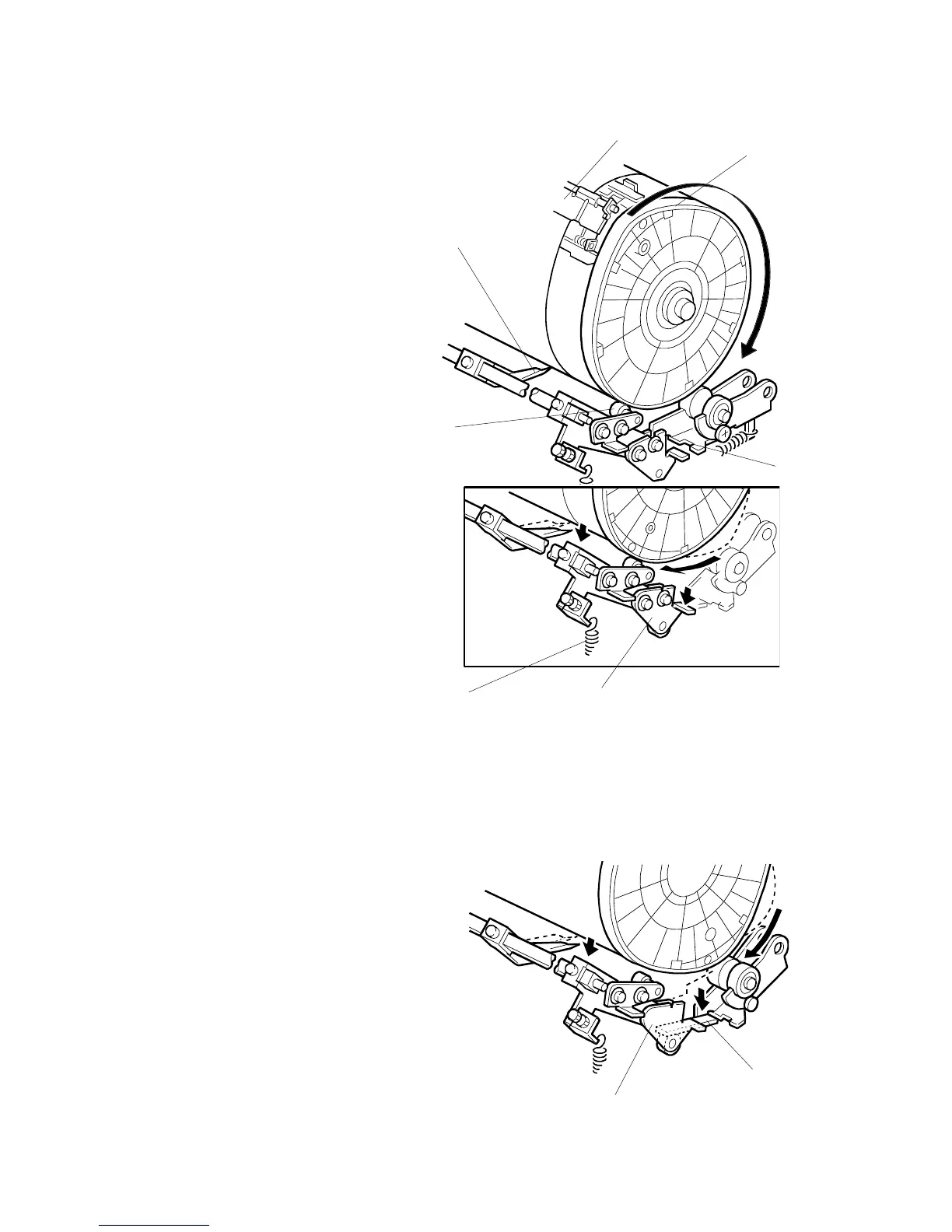

2.7.4 EXIT PAWL DRIVE MECHANISM

During printing, the distance

between the exit pawl [A] and

the drum is very small to

prevent paper wrap jams.

However, when the master

clamper [B] approaches the exit

pawl (as the drum turns), the

pawl has to be moved away

from the drum to prevent it from

being damaged by the master

clamper. This is controlled by

the front drum flange [C], which

is cam-shaped, and the cam

follower [E] on the exit pawl

shaft.

When the cam follower is not

pushed away by the drum

flange, the exit pawl is

positioned close to the drum

surface, by the tension of

spring [G].

As the master clamper

approaches the exit pawl, the

high point of the drum flange

cam [C] moves into contact

with the cam follower [E]

pushing it down. This moves

the cam follower arm [F]

downwards. The pawl shaft

turns clockwise to move the pawl away from the drum.

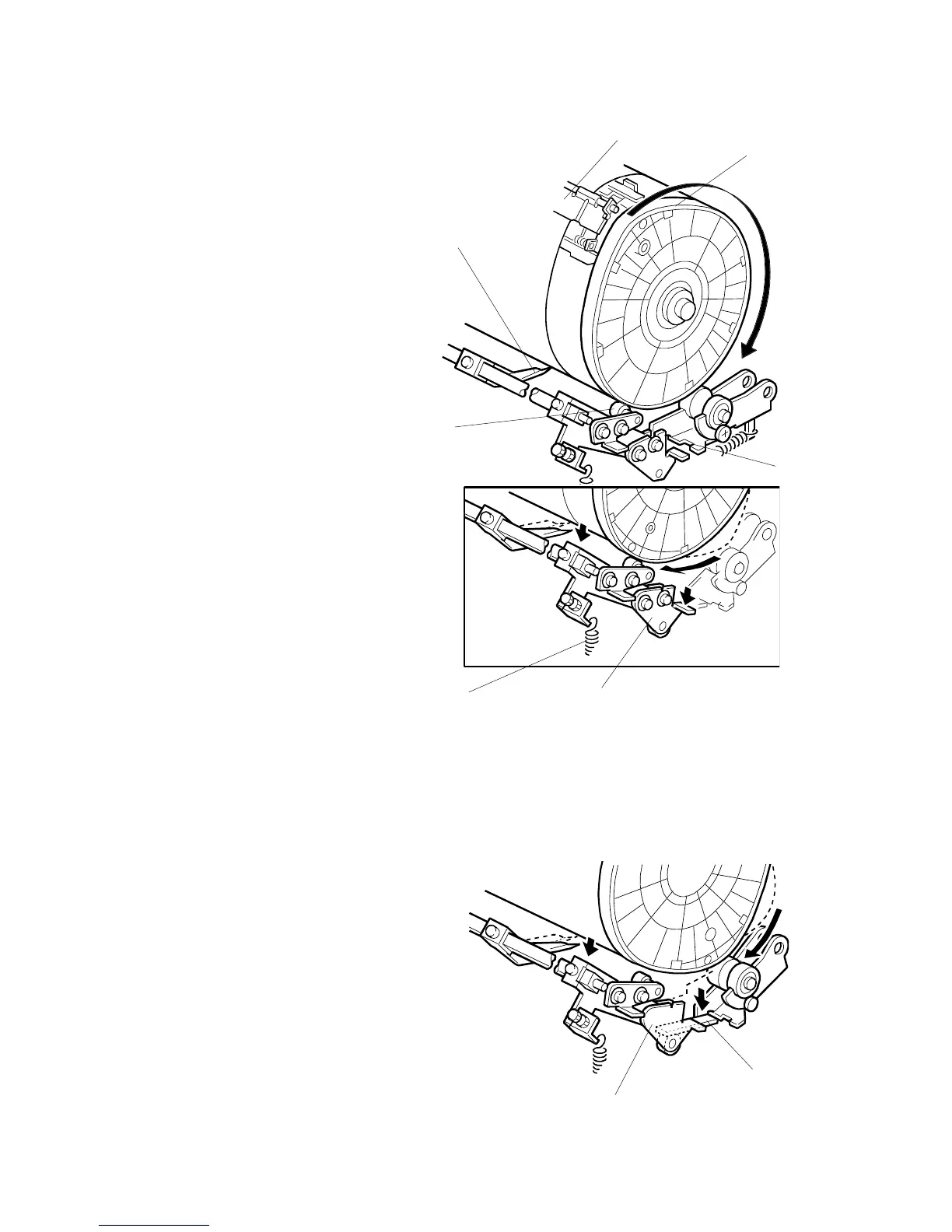

When printing finishes and the

printing pressure is released, the

cam follower arm [F] is engaged by

the printing pressure release arm

[D] and held in the lower position.

Therefore, after printing finishes,

the cam follower is out of contact

with the cam, and the exit pawl

moves away from the drum to its

normal position.

C231D561.WMF

C231D562.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[D]

[F]

Loading...

Loading...