DRIVE AND CUTTING MECHANISM

7-3

Tape Marker

C532

C532 SM

2.2 DRIVE AND CUTTING MECHANISM

The tape dispenser uses a stepping motor, which is driven at 460 pulses per

second, as a drive motor.

When the print counter of the main body becomes 0, the start signal from the main

body changes from high (+5 VDC) to low (0 VDC) to start the timer on the tape

dispenser board. When the start signal changes to high 10 milliseconds later, the

drive motor [A] starts to rotate counterclockwise to feed tape. However, since a

one-way bearing is mounted in the cam drive gear [B], the cutter cam [C] does not

rotate.

The drive motor starts rotating in the opposite direction 2,500 milliseconds after the

timer starts. At this time, the tape has been fed out 250 mm (9.8") from the tape

dispenser. The drive motor rotates the cam drive gear clockwise and the eccentric

shaped cutter cam presses down the cutter arm [D]. The cutter [E] then goes down

to cut the tape. The cutter spring [F] returns the cutter to its original position. After

the cutter home position sensor [G] detects the cutter actuator [H], the drive motor

stops and the tape dispenser board sends the task completion signal to the main

body.

C532D502.PCX

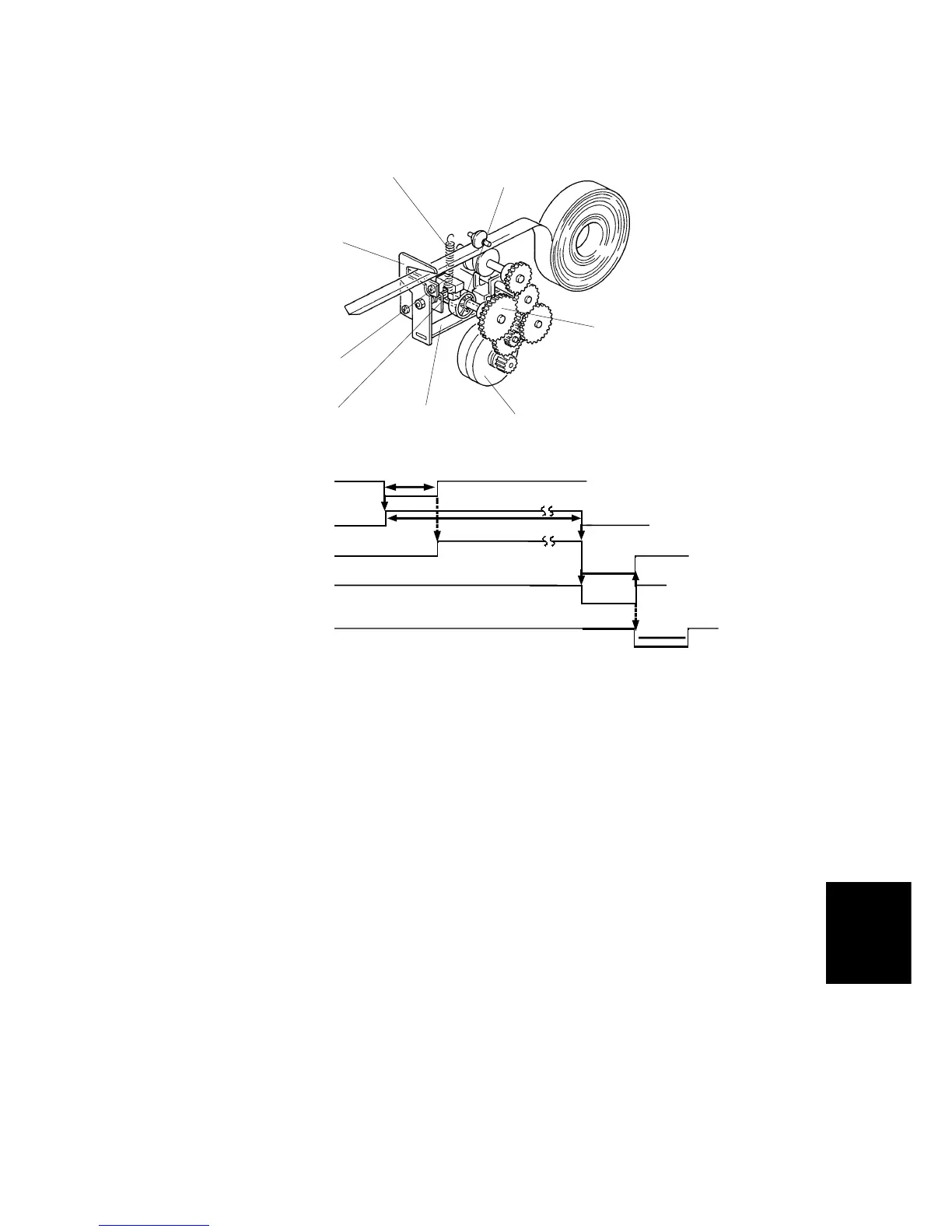

10 ms

2500 ms

Forward

Reverse

100 ms

Start Signal

Timer

Drive Motor

Task Completion

Signal

Home Position

Sensor

C532D503.WMF

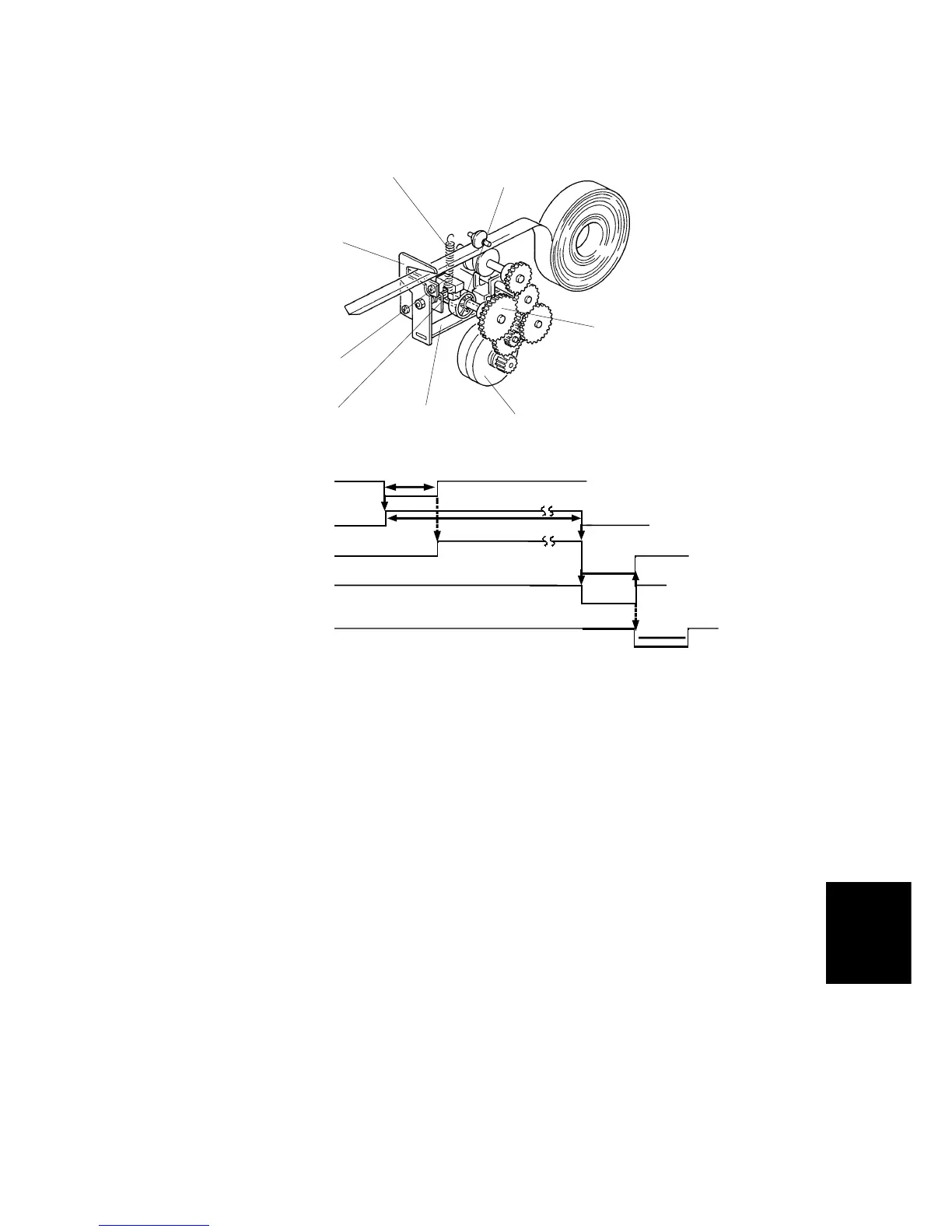

[A]

[B]

[E]

[F]

[G]

[H]

[D]

[C]

Loading...

Loading...