MASTER FEED

2-26

C231/C237/C238 SM

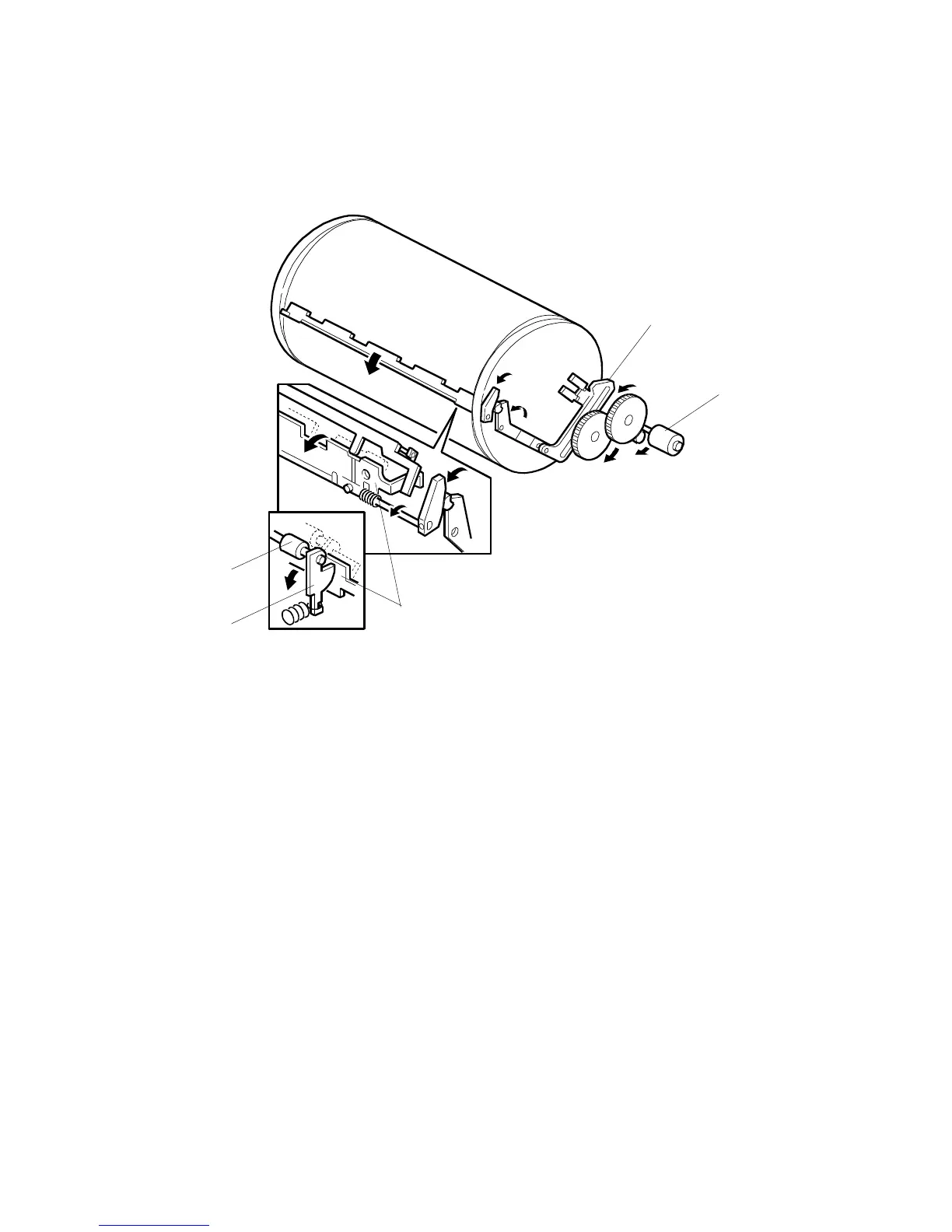

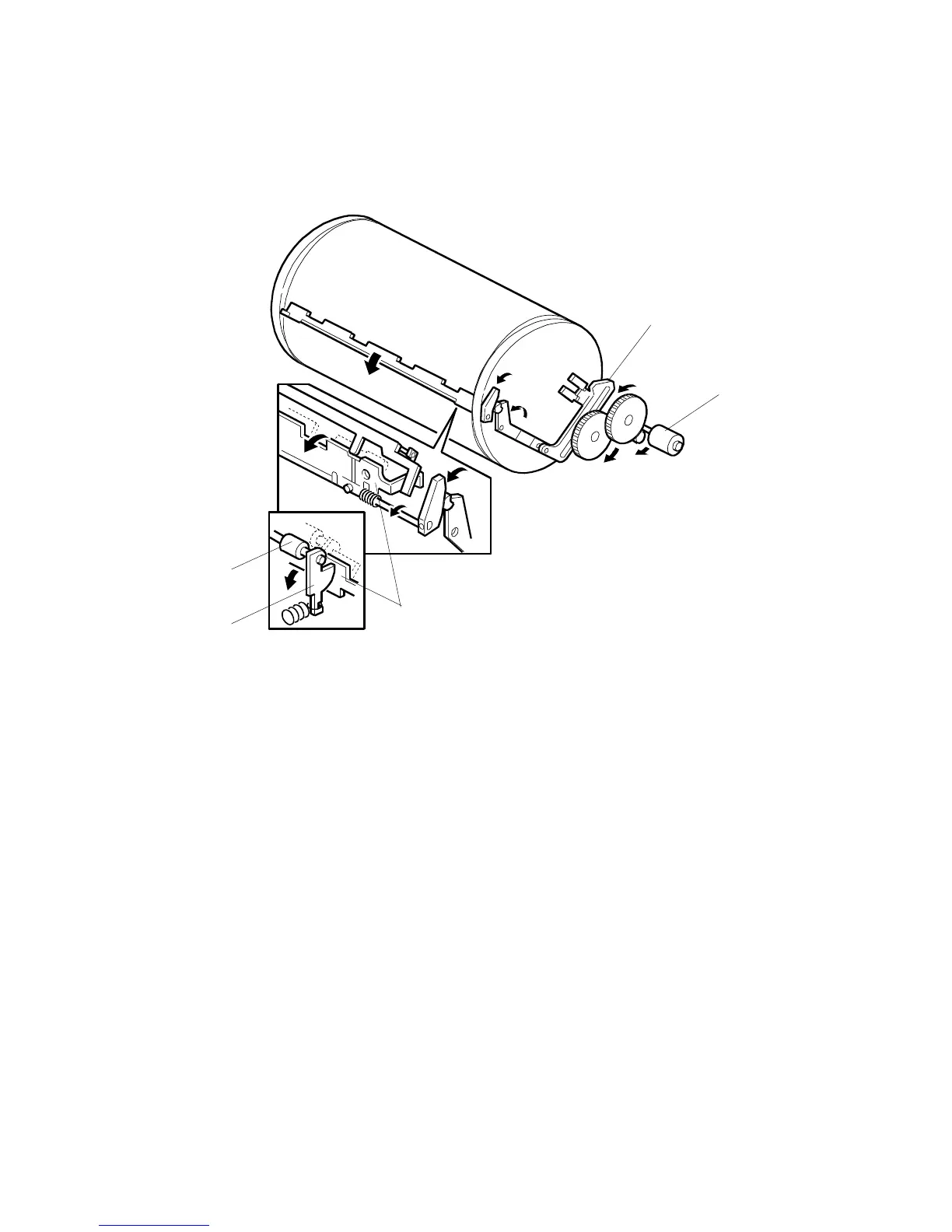

2.4.3 MASTER CLAMPER OPERATION AND TENSION ROLLER

RELEASE MECHANISM

After the master has been ejected, the drum is stopped at the master feed position.

At this time, the clamper motor [A] drives the moving link [B] to open the master

clamper [C].

The tension roller [D] is normally pressed against the master feed guide plate to

apply tension to the master during the master wrapping operation. When the

clamper opens, the clamper pushes the tension roller arms [E] and moves the

tension roller away from the guide plate to allow the master to be fed into the

master clamper.

To close the master clamper, the clamper motor reverses.

NOTE:

The clamper open and close sensors identifies the link [B] position. Refer

to the Master Eject section for details.

C231D537.WMF

[A]

[B]

[C]

[D]

[E]

Loading...

Loading...