MASTER EJECT

2-22

C231/C237/C238 SM

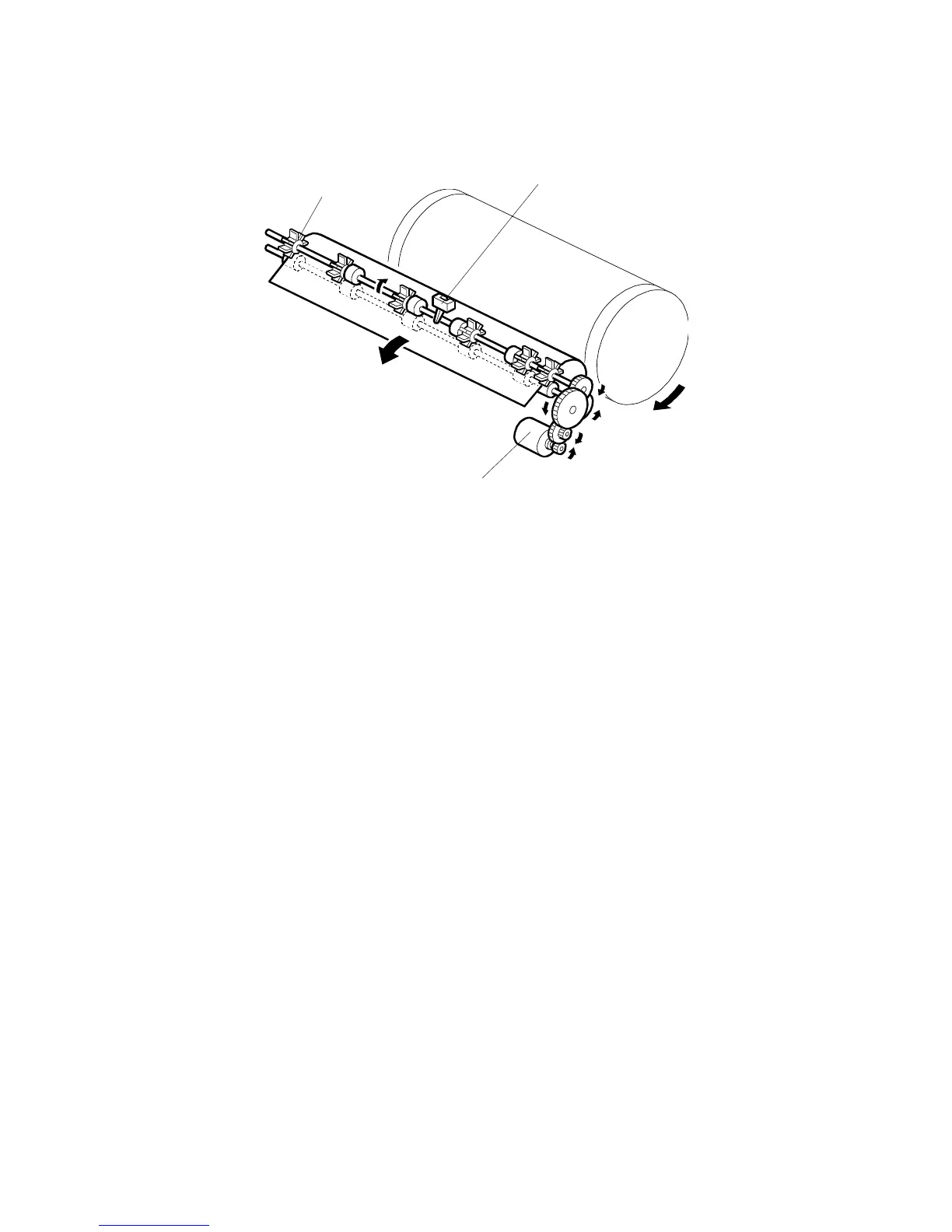

2.3.3 MASTER EJECT ROLLER MECHANISM

The master eject rollers are driven by the master eject motor [A] through idle gears.

The upper eject roller [B] has paddles to assure the master pick-up.

When the master clamper is opened and the master's leading edge is released

from the master clamper, the master eject motor turns on for 0.6 seconds to pick

up the leading edge of the master.

When the master eject motor is turned off, the clamper motor reverses to close the

master clamper.

The drum then starts turning at the slowest speed (30 rpm). At the same time, the

master eject rollers turn again to feed the master into the master eject box.

After one turn of the drum, the master eject motor stops. The drum turns for an

additional half turn, stopping 109 encoder pulses after the feed start timing sensor

is actuated (this means that the drum is at the master feed position).

The master eject sensor [C] is used to detect master eject jams.

C231D532.WMF

[A]

[B]

[C]

Loading...

Loading...