MASTER EJECT SECTION

C231/C237/C238 6-2 SM

6.2 MASTER EJECT SECTION

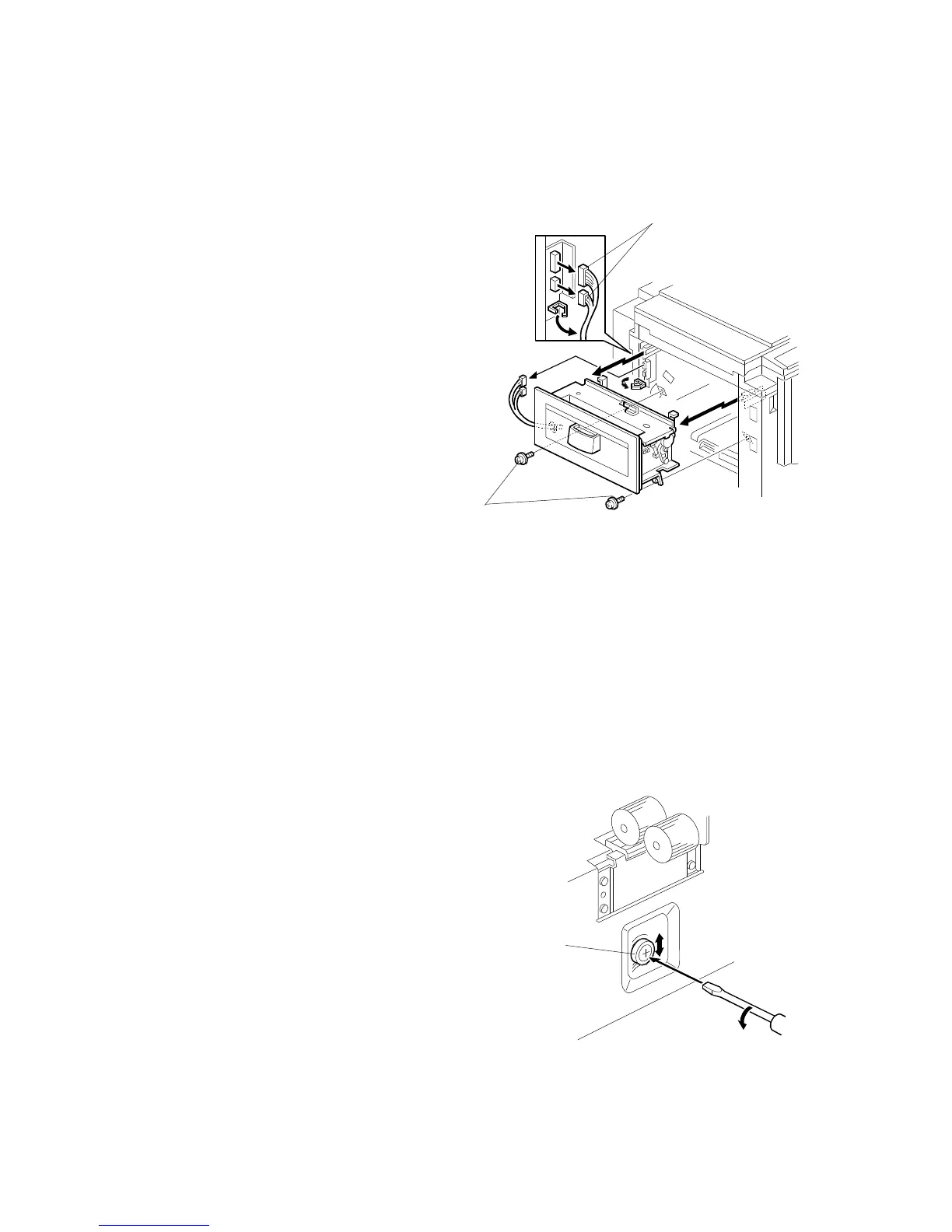

6.2.1 MASTER EJECT UNIT REMOVAL

1. Turn off the main switch and

disconnect the power plug.

2. Remove the 2 screws [A].

3. Pull out the master eject unit.

4. Disconnect the 2 connectors [B].

6.3 PAPER FEED SECTION

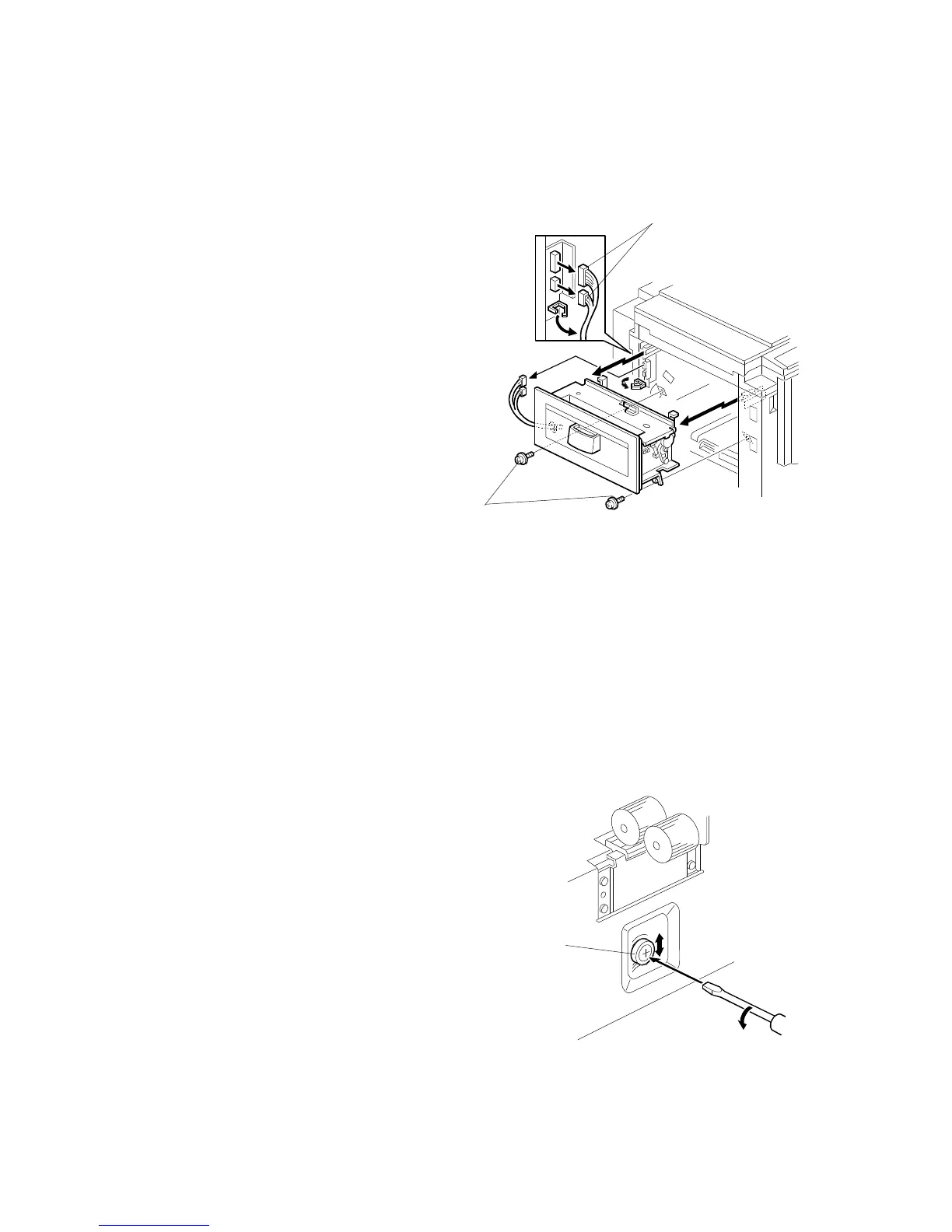

6.3.1 PAPER SEPARATION PRESSURE ADJUSTMENT

Purpose:

To ensure that the friction pad exerts sufficient pressure for smooth printing paper

separation.

NOTE:

As the default, the adjusting screw [A] is set at the 2nd position from the

top. The amount of separation pressure is the same as for the C231 model.

This change allows the separation pressure to be lowered more, which

makes it more effective for thin paper feed and separation.

Adjust the paper separation pressure by loosening

and moving the adjusting screw [A] up or down.

•

Moving up the screw

⇒

Increases the paper separation pressure

•

Moving down the screw

⇒

Decreases the paper separation pressure

Using this adjustment to cure non-feed and multi-

feed is not simple and depends on many factors.

Adjust using trial and error to get the best results.

Tighten the screw after the adjustment.

C237R500.WMF

C237R542.WMF

[A]

[B]

[A]

Loading...

Loading...