DRUM

SM 3-53 C267

C267 Service

Manual

3.9.7 INK DETECTION ADJUSTMENT

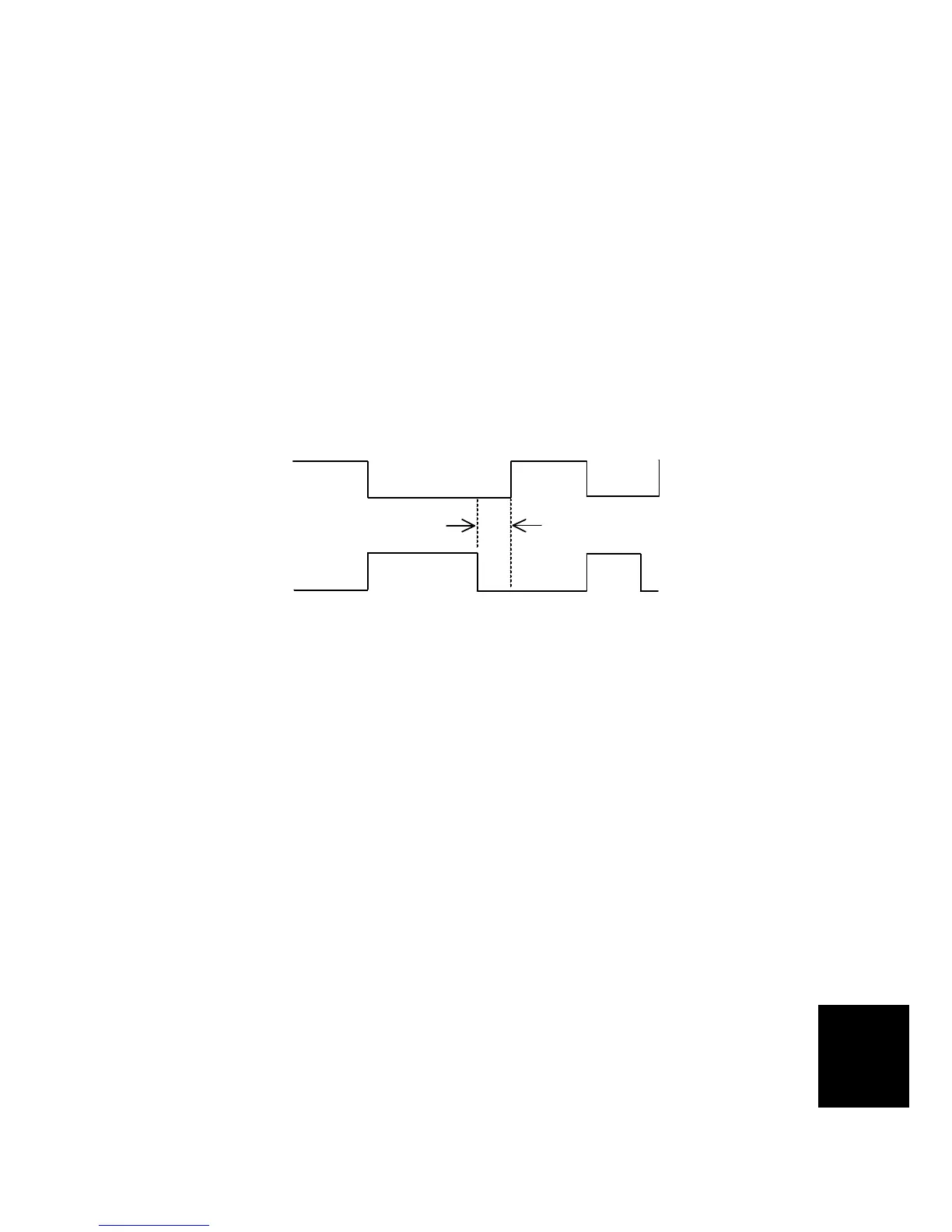

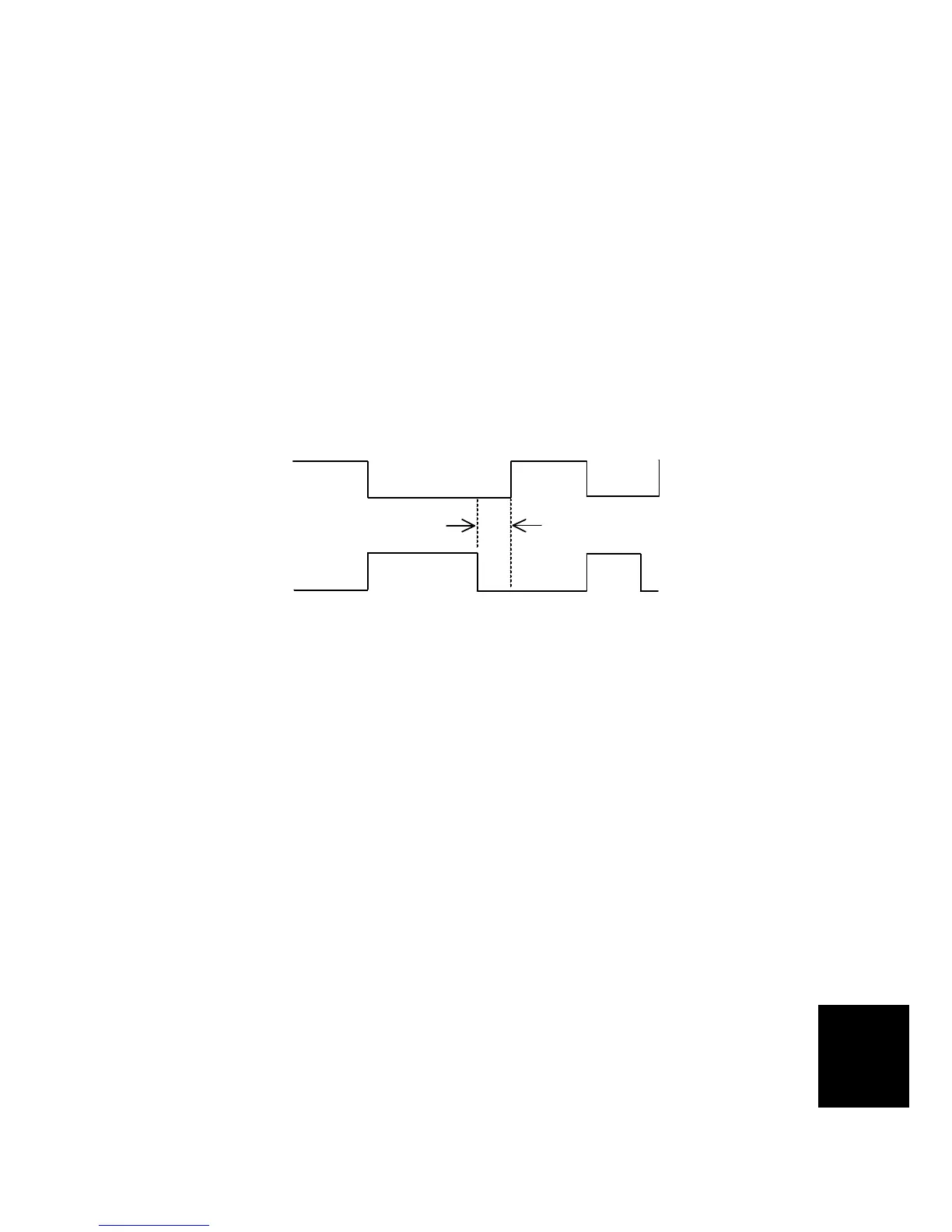

Using an Oscilloscope

Purpose: To ensure that the CPU detects a no ink condition.

Standard: 4.0 ± 0.2 μsec

NOTE:

1) Before attempting this procedure, wipe off the ink around the ink roller.

To do this, set SP2-10 (Ink Detection) to OFF, and feed paper until ink

ends.

2) This adjustment is required every time the MPU has been replaced.

3) Normally, the simple method is sufficient. But, the oscilloscope method

is more accurate. Use the oscilloscope method if you cannot adjust the

sensor to the required value with the simple method, or if ink flooding

problems occur after adjustment with the simple method.

1. Turn off the main switch and disconnect the power plug.

2. Remove the rear cover.

3. Connect the CH1 probe of an oscilloscope to TP25 (INK1), the CH2 probe to

TP23 (INK2). Select the 2-microsecond range on the oscilloscope.

4. Connect the power plug and turn on the main switch.

5. Make sure that the waveform is as shown in the illustration while the ink end

indicator lights.

6. If it is not correct, adjust the ON timing of the detection signal by turning VR1

beside the test pins.

NOTE:

1) If the ink detection off mode has been selected with SP2-10, do not

forget to return it to the default (detection on).

C267R912.WMF

CH1

(Standard signal)

CH2

(Detection signal)

4.0 ± 0.2

Loading...

Loading...