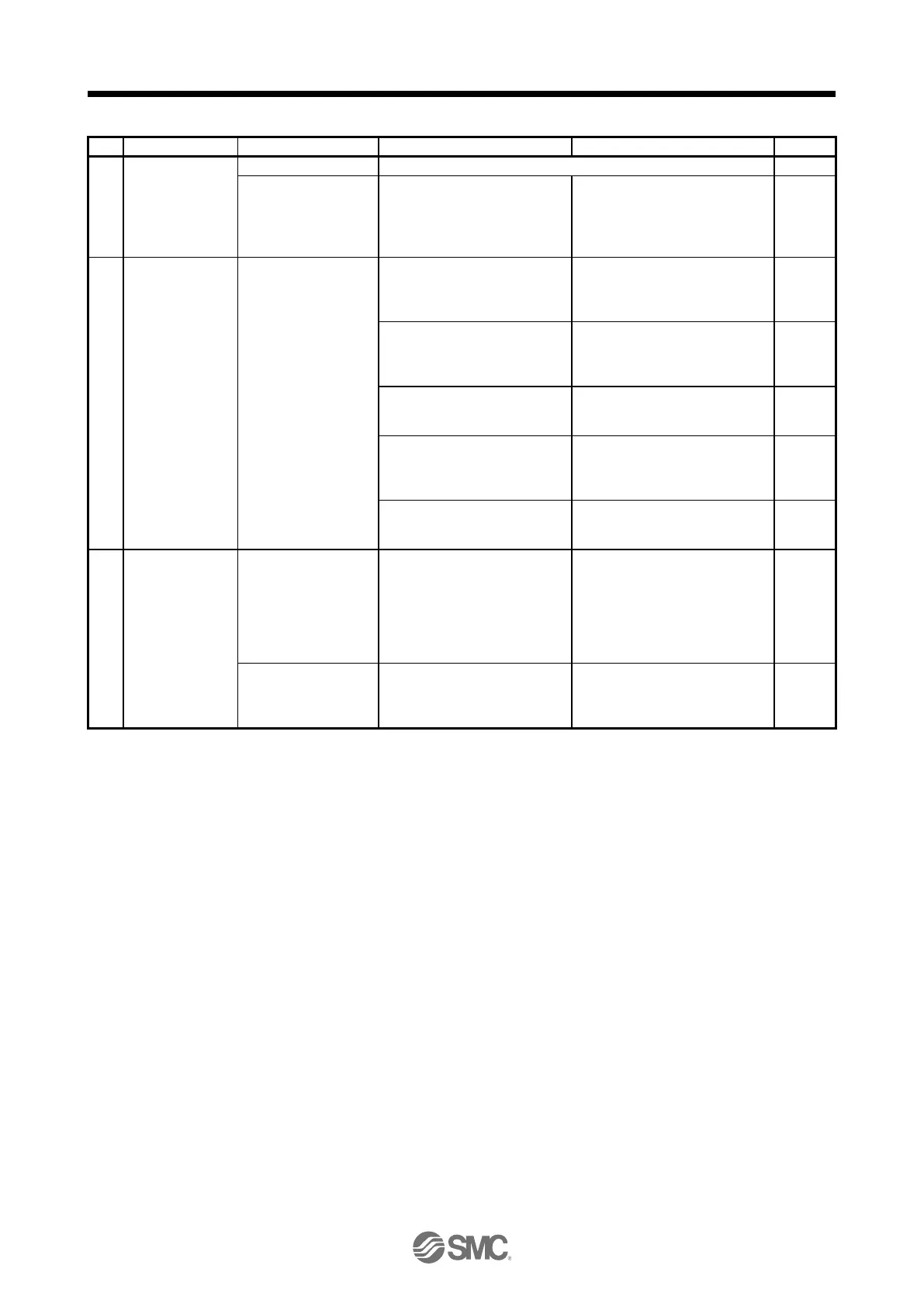

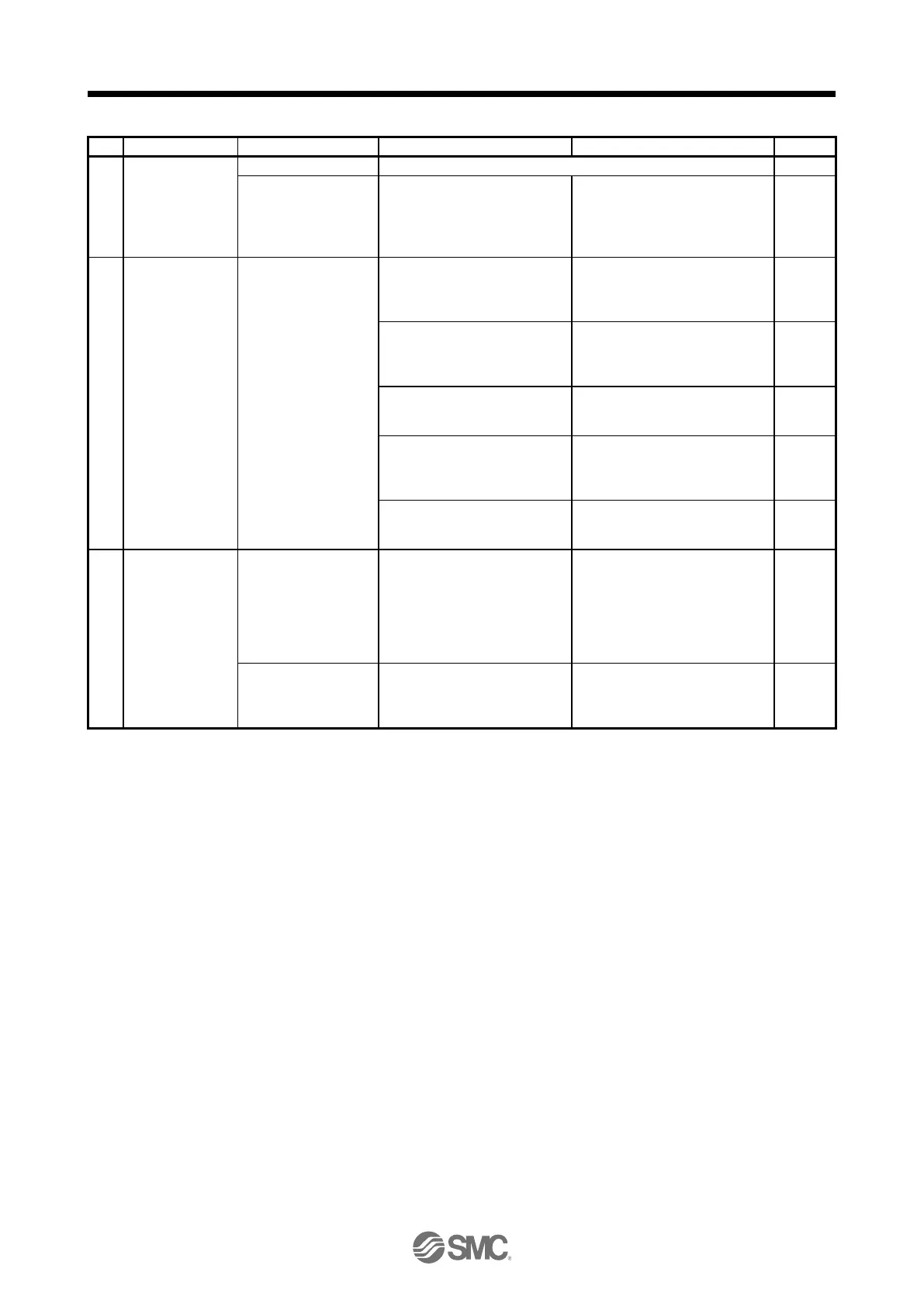

Switch on SON

(Servo-on).

Refer to chapter 8 and remove cause.

Servo motor shaft is

not servo-locked.

(Servo motor shaft is

free.)

1. Check the display to see if

the driver is ready to operate.

2. Check the external I/O signal

indication (section 4.5.7) to

see if SON (Servo-on) is on.

1. SON (Servo-on) is not input.

(wiring mistake)

2. 24 V DC power is not supplied

to DICOM.

Switch on ST1

(Forward rotation

start) or ST2

(Reverse rotation

start).

Servo motor does not

rotate.

Call the status display (section

4.5.3) and check the input

voltage of VC (Analog speed

command).

Analog speed command is 0 V.

Call the external I/O signal

display (section 4.5.7) and check

the on/off status of the input

signal.

LSP, LSN, ST1, and ST2 are off.

Check the internal speed

commands 1 to 7 ([Pr. PC05] to

[Pr. PC11]).

Check the forward rotation

torque limit ([Pr. PA11]) and the

reverse rotation torque limit ([Pr.

PA12]).

Torque limit level is too low as

compared to the load torque.

When TLA (Analog torque limit)

is usable, check the input

voltage on the status display.

Torque limit level is too low as

compared to the load torque.

Rotation ripples (speed

fluctuations) are large

at low speed.

Make gain adjustment in the

following procedure.

1. Increase the auto tuning

response level.

2. Repeat acceleration and

deceleration three times or

more to complete auto tuning.

Large load inertia

moment causes the

servo motor shaft to

oscillate side to side.

If the servo motor may be run

with safety, repeat acceleration

and deceleration three times or

more to complete auto tuning.

Loading...

Loading...