16.23 HOW TO SET THE ELECTRONIC GEAR

16.23.1 Electronic gear settings in the point table method and program method

(1) Setting [mm], [inch], or [pulse] with "Position data unit" of [Pr. PT01].

Adjust [Pr. PA06] and [Pr. PA07] so that the driver setting matches with the travel distance of the

machine.

P

t

: Servo motor encoder resolution: 4194304 [pulse/rev]

ΔS: Travel distance per servo motor revolution [mm/rev]/[inch/rev]/[pulse/rev]

CMX/CDV = P

t

/ΔS

Set the electronic gear within the following range. Setting out of the range will trigger [AL. 37 Parameter

error].

Electronic gear setting range

1/13825 < CMX/CDV < 16967

The following setting example explains how to calculate the electronic gear.

To calculate the electronic gear, the following specification symbols are

required.

Pb: Ball screw lead [mm]

1/n: Reduction ratio

Pt: Servo motor encoder resolution [pulse/rev]

ΔS: Travel distance per servo motor revolution [mm/rev]

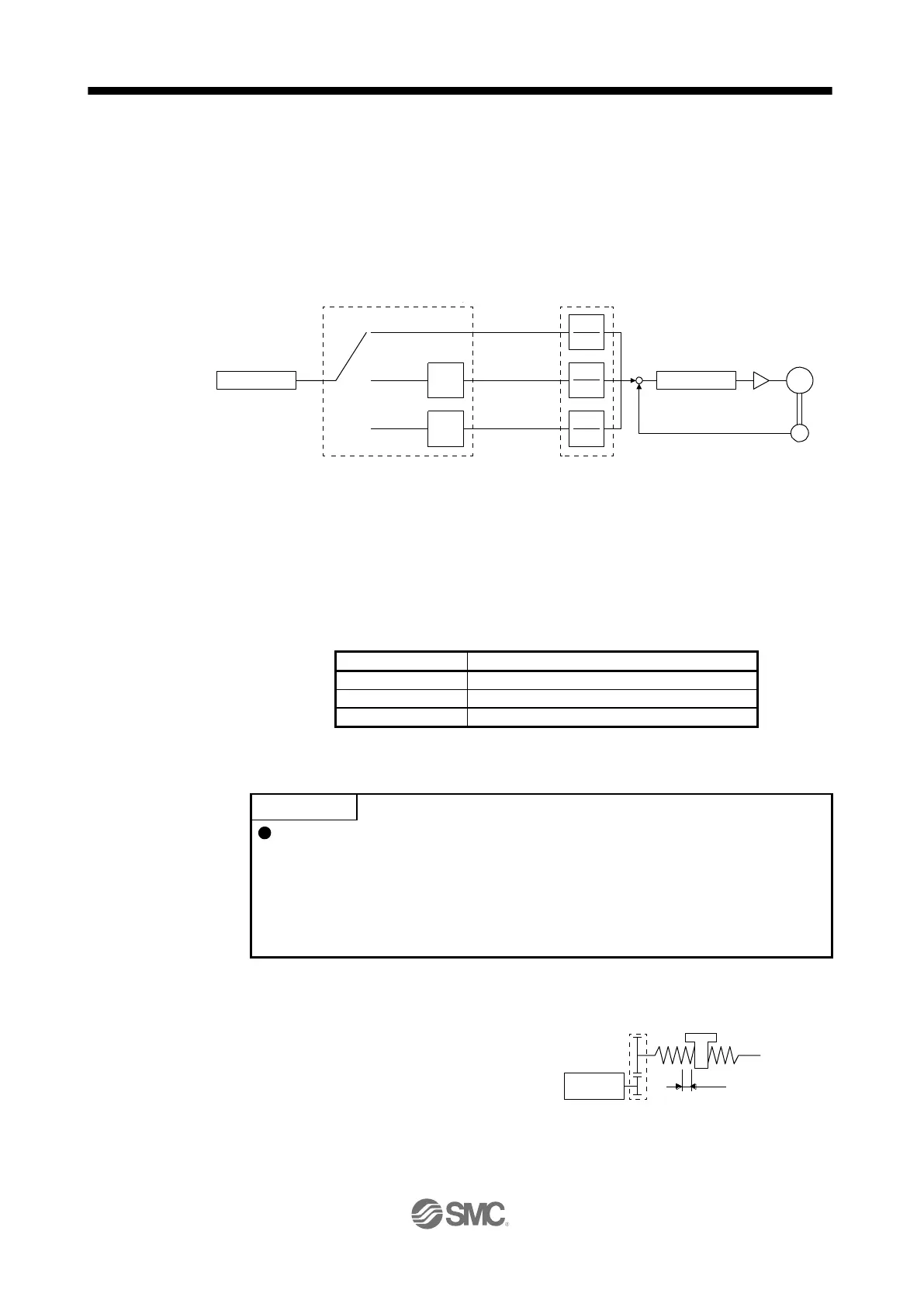

(a) Setting example of a ball screw

Machine specifications

Ball screw lead Pb = 10 [mm]

Reduction ratio: 1/n = Z

1

/Z

2

= 1/2

Z

1

: Number of gear teeth on servo motor side

Z

2

: Number of gear teeth on load gear

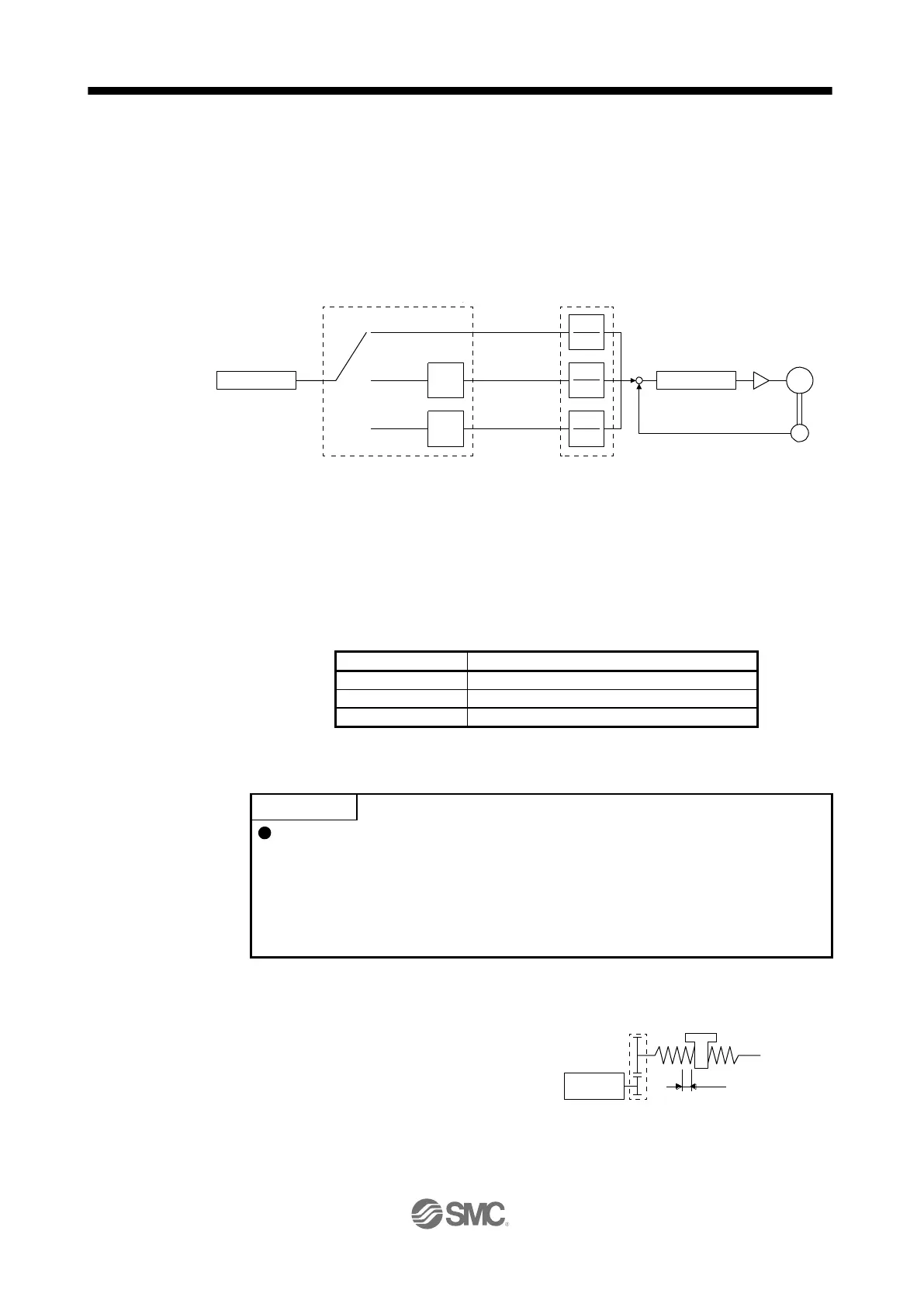

CDV

Travel distance

"0" (initial value)

CMX

CDV

CMX

Deviation counter

+

-

Electronic gear

([Pr. PA06]/[Pr. PA07])

Servo motor

Encoder

M

X32

X16

"2"

CDV

CMX

"3"

Electronic gear selection

(x _ _ _ ) ([Pr. PA21]) (Note)

Servo motor encoder resolution

4194304 [pulse/rev]

Pb = 10 [mm]

Z1

1/n = Z1/Z2 = 1/2

Z2

1/n

Loading...

Loading...