10. CHARACTERISTICS

10 - 7

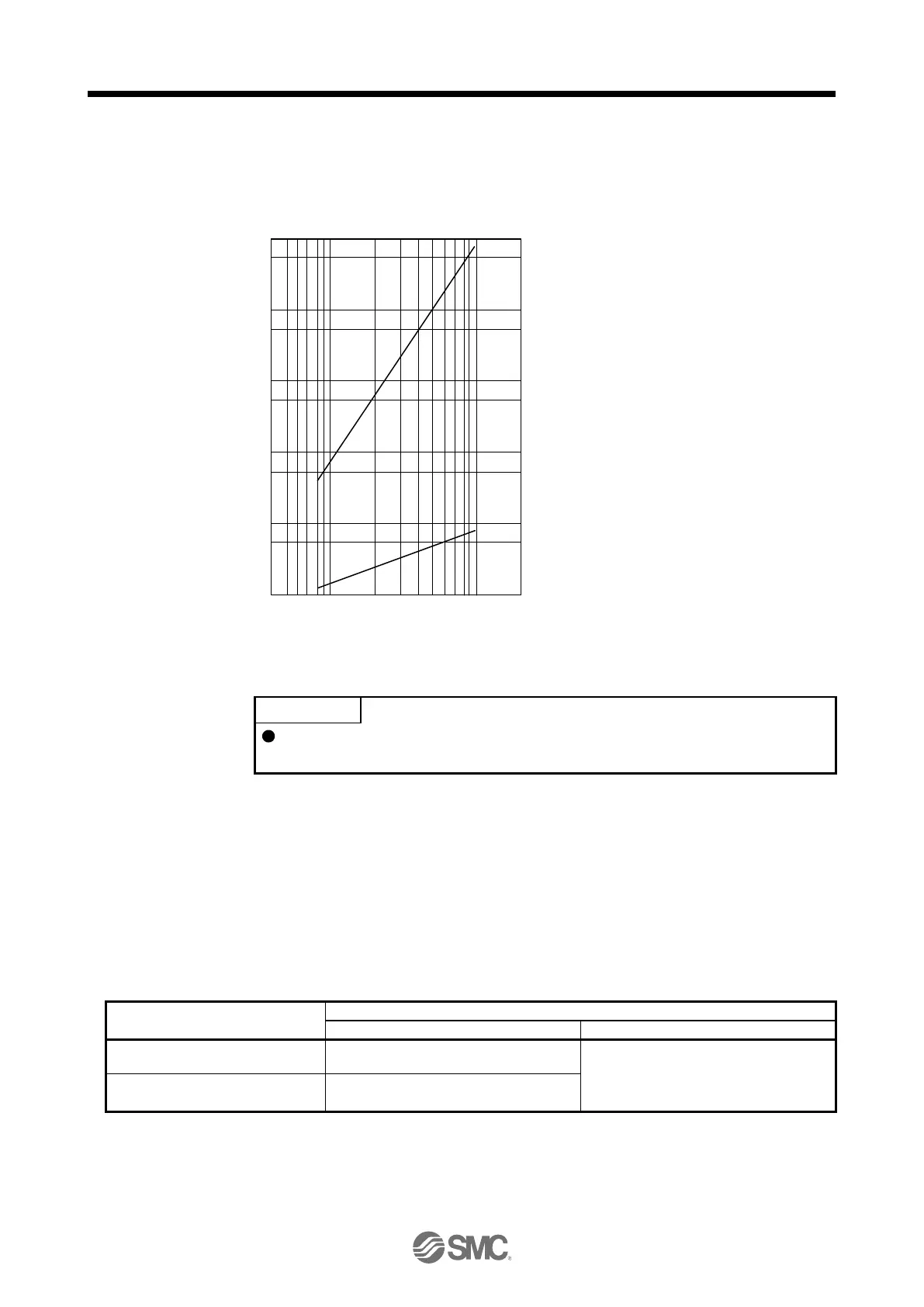

10.4 Cable bending life

The bending life of the cables is shown below. This graph calculated values. Since they are not

guaranteed values, provide a little allowance for these values. The minimum bending radius : Min.

45mm.

a: Long bending life encoder cable

Long bending life motor power cable

Long bending life electromagnetic brake cable

SSCNET III cable using long distance cable

b: Standard encoder cable

Standard motor power cable

Standard electromagnetic brake cable

SSCNET III cable using inside panel standard cord

SSCNET III cable using outside panel standard cable

Number of bending times [time]

1 × 10

8

5 × 10

7

1 × 10

7

5 × 10

6

1 × 10

6

5 × 10

5

1 × 10

5

5 × 10

4

1 × 10

4

5 × 10

3

1 × 10

3

Bend radius [mm]

4 7 10 20 40 70 100 200

b

a

10.5 Inrush currents at power-on of main circuit and control circuit

For a driver of LECSB2-T8 or less, the inrush current values can change

depending on frequency of turning on/off the power and ambient temperature.

Since large inrush currents flow in the power supplies, always use molded-case circuit breakers and

magnetic contactors. (Refer to section 11.6.)

When circuit protectors are used, it is recommended that the inertia delay type, which is not tripped by an

inrush current, be used.

The following table indicates the inrush currents (reference data) that will flow when 240 V AC is applied

at the power supply capacity of 2500 kVA and the wiring length of 1 m. Even when you use a 1-phase

200 V AC power supply with LECSB2-T5 to LECSB2-T9, the inrush currents of the main circuit power

supply is the same.

Main circuit power supply (L1, L2, and L3)

Control circuit power supply (L11 and L21)

LECSB2-T5/ LECSB2-T7/

LECSB2-T8

30 A (attenuated to approx. 3 A in 20 ms)

20 A to 30 A

(attenuated to approx. 1 A in 20 ms)

34 A (attenuated to approx. 7 A in 20 ms)

Lobot encoder cable

Lobot motor power cable

Lobot lock cable

Standard encoder cable

Standard motor power cable

Standard lock cable

Loading...

Loading...