8. TROUBLESHOOTING

8 - 79

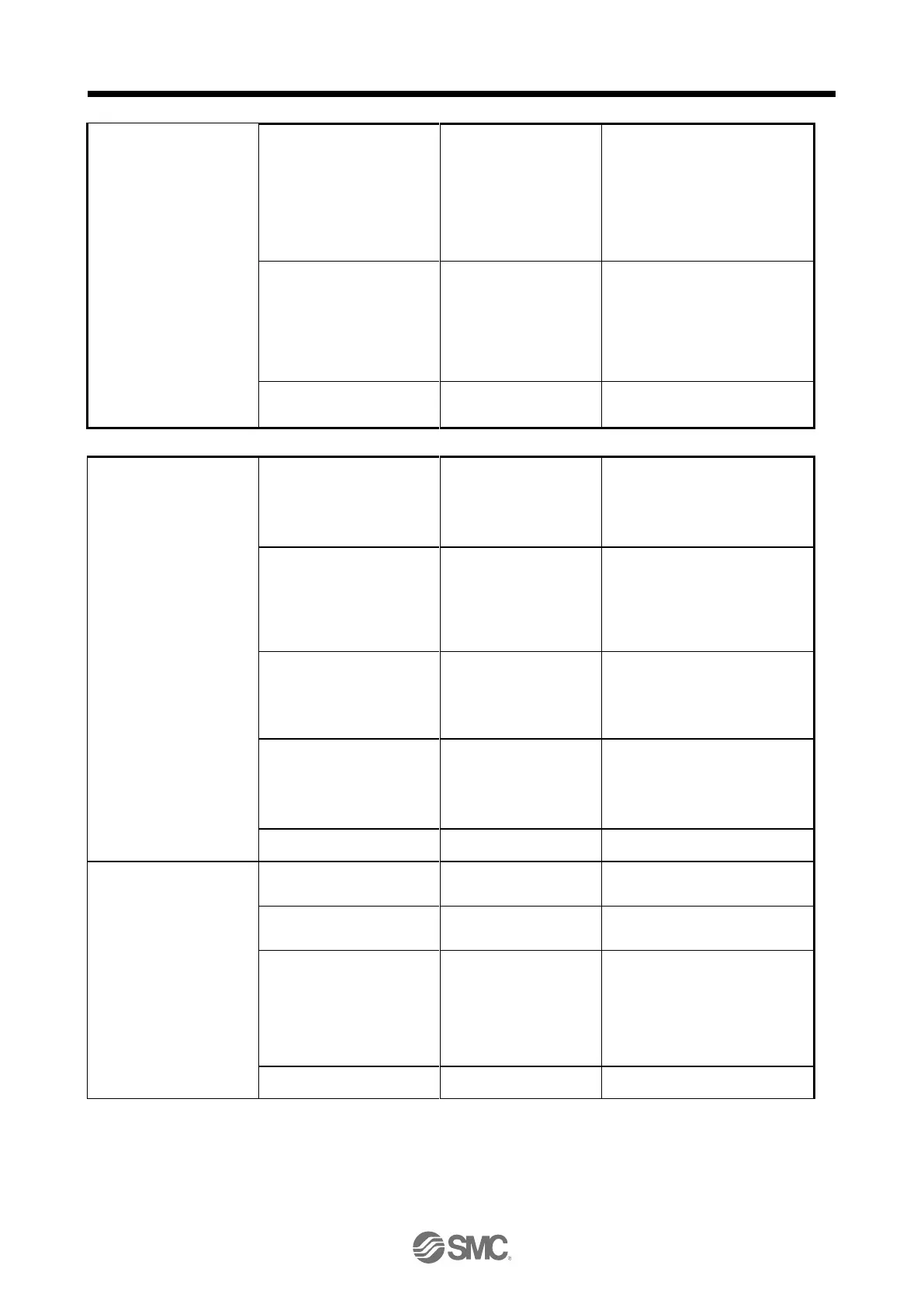

A restoration position deviates

at restoration of power for the

absolute position detection

system.

The motor was rotated

exceeding the maximum

permissible speed at power

failure (6000 r/min) by an

external force during driver

power off.

(Note: The acceleration time is

0.2 s or less.)

Check if the motor was

accelerated suddenly to

6000 r/ min by an external

force.

Extend the acceleration time.

The driver power turned on while

the servo motor was rotated

exceeding 3000 r/min by an

external force.

Check if the driver power

turned on while the servo

motor was rotated exceeding

3000 r/min by an external

force.

Review the power-on timing.

Transfer data to the controller is

incorrect.

Check the ABS data with

setup software (MR

Configurator2

TM

).

Review the controller programs.

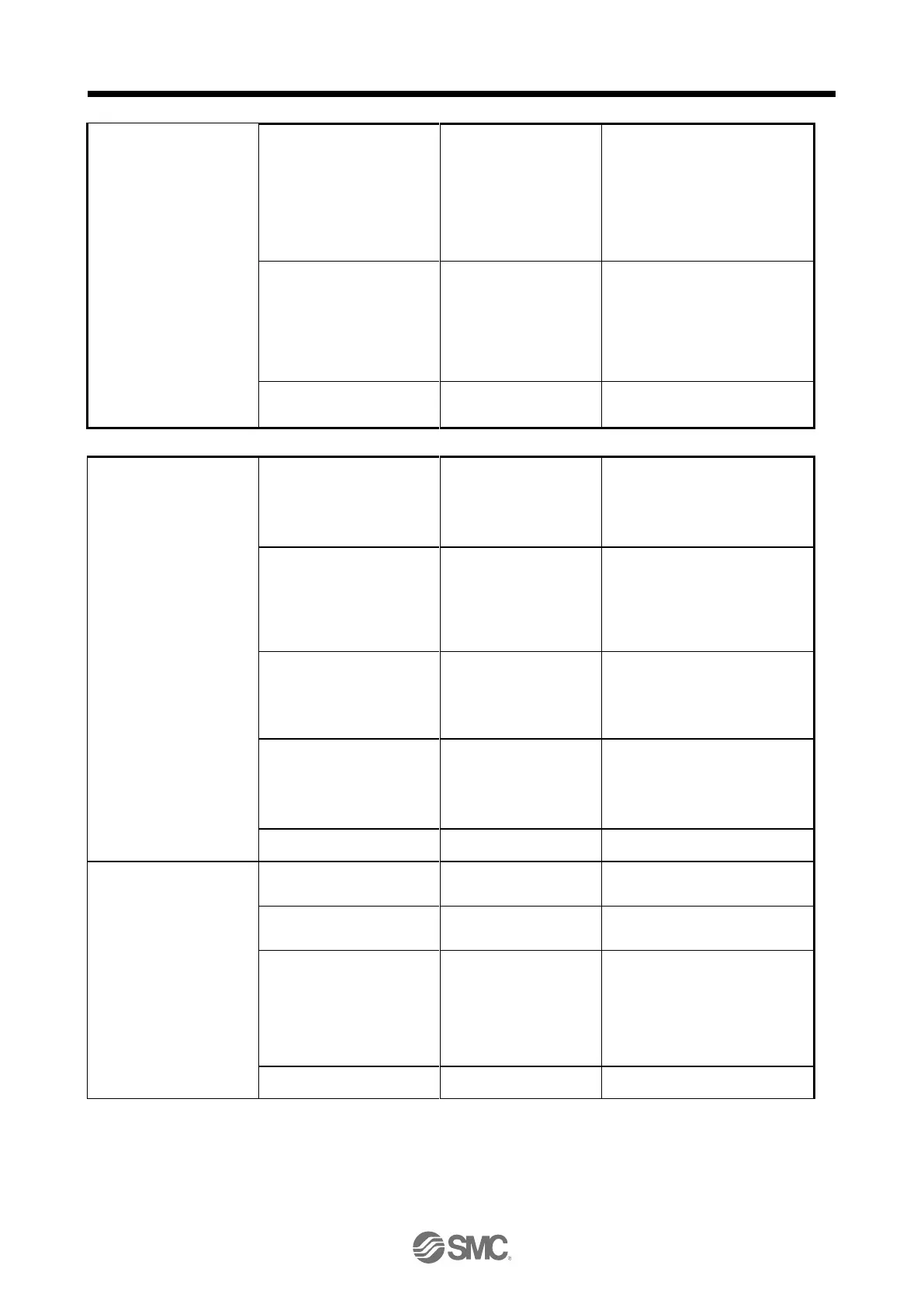

Overshoot/undershoot

occurs.

The servo gain is low or too

high.

The response of auto tuning is

low or too high.

Check the velocity waveform

with a graph using setup

software (MR

Configurator2

TM

) if

overshoot/ undershoot is

occurring.

Adjust the response of auto tuning

and execute the gain adjustment

again.

The setting of [Pr. PB06 Load to

[GF]

motor inertia ratio/ load to motor

mass ratio] is incorrect.

Check that the setting value

of [Pr.PB06 Load to motor

inertia ratio/load to motor

mass ratio] and the

actual load moment of

inertia or

load mass are matched.

Capacity shortage or shortage

of the maximum torque (thrust)

due to too large load.

Check the instantaneous

torque using status display if

the maximum torque

(maximum thrust) exceeds

the torque limit value (thrust

limit value).

Reduce the effective load ratio by

increasing acceleration/

deceleration time and reducing load.

The setting of the torque limit is

incorrect.

Check the instantaneous

torque using status display if

the maximum torque

(maximum thrust) exceeds

the torque limit

value (thrust limit value).

Review the torque limit setting.

Backlash of the machine part is

large.

Check if there is a backlash

on the machine part.

Adjust the backlash on the

coupling and machine part.

A communication with driver

fails using setup software (MR

Configurator2

TM

).

(For details, refer to Help of

setup software (MR

Configurator2

TM

).)

The communication setting is

incorrect.

Check the communication

setting such as baud rate

and ports.

Set the communication setting

correctly.

A model is being connected

other than the model set in

model selection.

Check if the model selection

is set correctly.

Set the mode selection correctly.

The driver was not set

correctly.

Check the bottom of the

USB

(Universal Serial Bus)

controller with the device

manager of the personal

computer if "MITSUBISHI

MELSERVO USB Controller"

is being displayed.

Delete an unknown device or

other devices, cycle the power of

the driver, and reset according to

Found New Hardware Wizard.

They are off-line status.

Check if they are off-line.

Loading...

Loading...