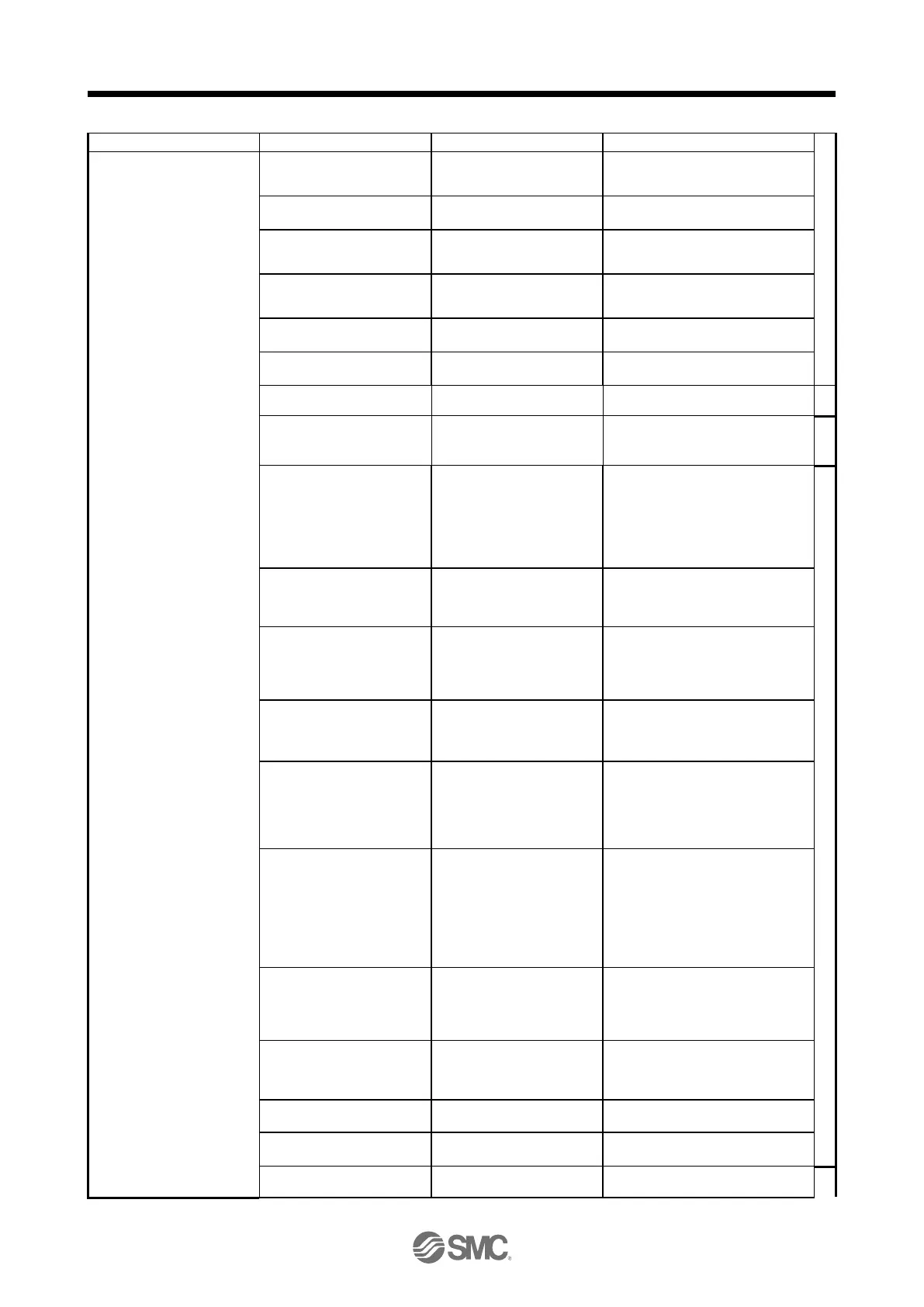

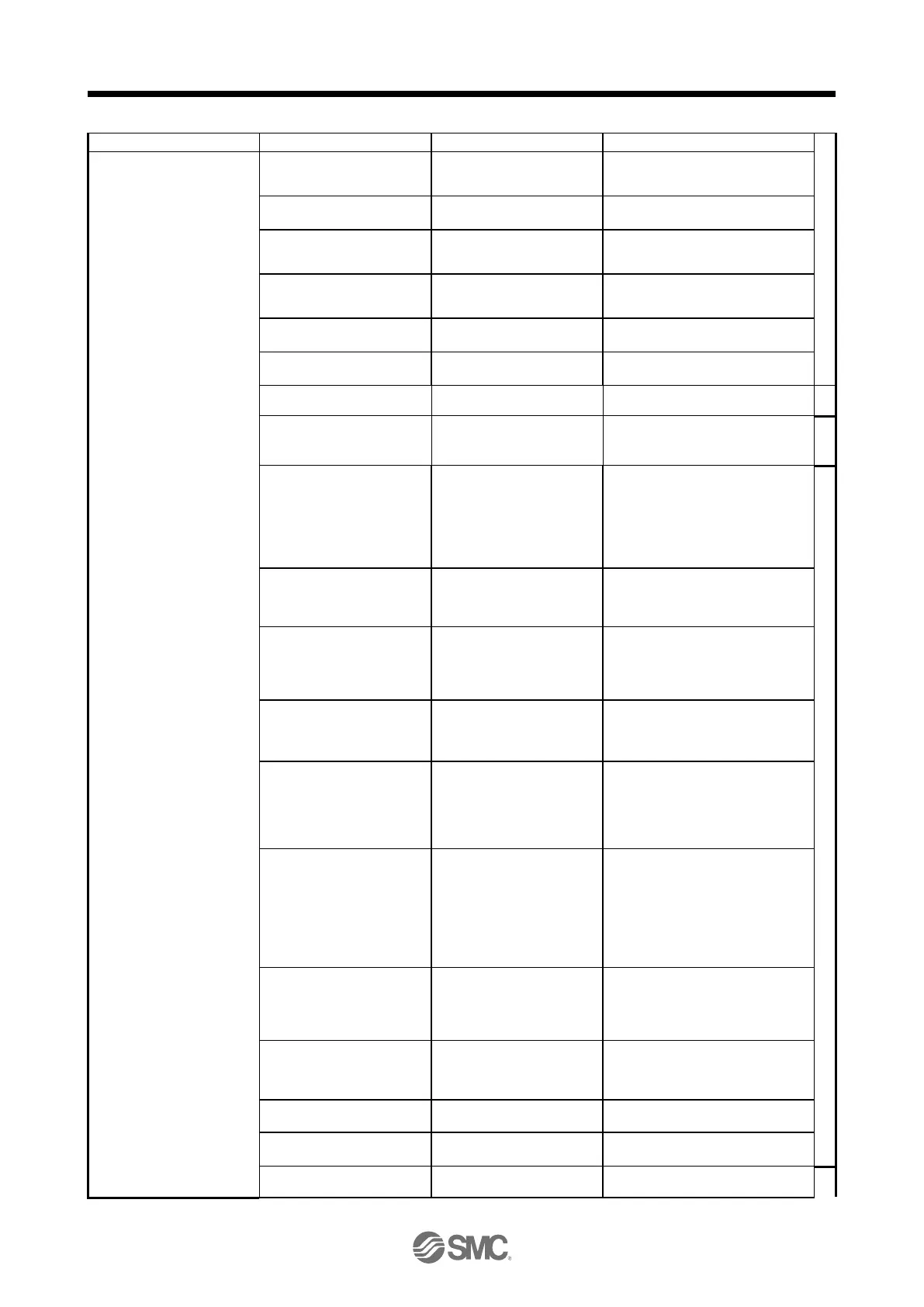

8. TROUBLESHOOTING

8 - 73

The setting of the torque limit

is incorrect.

Check if the torque limit is "0".

[Pr. PA11] and [Pr. PA12], or

analog input

Machine is interfering with the

motor.

Check if machine is

interfering.

For a servo motor with an

electromagnetic brake, the

lock has not released.

Check the power supply of the

electromagnetic brake.

Turn on the electromagnetic brake

power.

LSP (Forward rotation stroke

end) and LSN (Reverse

rotation stroke end) are not on.

Check if [AL. 99] is

occurring.

SON (Servo-on) is not on.

Check the SON (Servo-on)

state.

Check the RES (Reset)

state.

The setting of the control

mode is incorrect.

Check the [Pr. PA01] setting.

The command pulse is not

inputted in the position control

mode.

Check if the pulse train is

outputted on the controller

side.

Review the setting on the

controller side.

The wiring of the command

pulse train signal is incorrect

in the position control mode.

Check the cumulative

command pulses using the

status display or setup

software (MR

Configurator2

TM

). Input the

pulse train command and

check if the display changes.

Review the wiring. When the

signal is used in open-collector

type, input 24 V DC to OPC.

The setting of the command

pulse input form is incorrect in

the position control mode.

Check that the pulse train form

outputted with the controller

and the setting of [Pr. PA13]

are matched.

Review the [Pr. PA13] setting.

Both of ST1 (Forward rotation

start) and ST2 (Reverse

rotation start) are on or off in

the speed control mode or the

positioning mode.

Check the status of ST1

(Forward rotation start) and

ST2 (Reverse rotation start).

Turn on ST1 (Forward rotation

start) or ST2 (Reverse rotation

start).

Both of RS1 (Forward rotation

selection) and RS2 (Reverse

rotation selection) are on or off

in the torque control mode.

Check the status of RS1

(Forward

rotation selection) and RS2

(Reverse rotation selection).

Turn on RS1 (Forward rotation

selection) or RS2 (Reverse

rotation selection).

The value selected in the

speed control mode or the

torque control mode is low.

Check SP1 (Speed selection

1),

SP2 (Speed selection 2), and

SP3 (Speed selection 3), and

then check if the selected

internal speed is correct.

Review the selections of SP1

(Speed selection 1), SP2 (Speed

selection 2), SP3 (Speed

selection 3), and setting of internal

speed.

The value selected in the

positioning mode (point table

method) with BCD input is

low.

Check SPD1 (Speed selection

1),

SPD2 (Speed selection 2),

SPD3

(Speed selection 3) and SPD4

(Speed selection 4), and then

check if the selected internal

speed is correct.

Review the wiring. Review the

selections of SPD1 (Speed

selection 1), SPD2 (Speed

selection 2), SPD3 (Speed

selection 3), SPD4 (Speed

selection 4), and setting of internal

speed.

An analog signal is not

inputted correctly.

Check the values of analog

speed command and analog

torque command using status

display or setup software (MR

Configurator2

TM

).

Input the analog signals correctly.

The ABS transfer mode is

selected when the absolute

position detection system is

used.

The settings of the electronic

gear are incorrect.

Check the setting value of the

electronic gear.

Set a proper value of the electronic

gear.

The setting of point tables is

incorrect.

Check the point table setting.

Review the point table setting.

Wiring or the command pulse

multiplication setting is

When using an MR-HDP01

manual pulse generator,

Review the wiring and the

command pulse multiplication

Loading...

Loading...