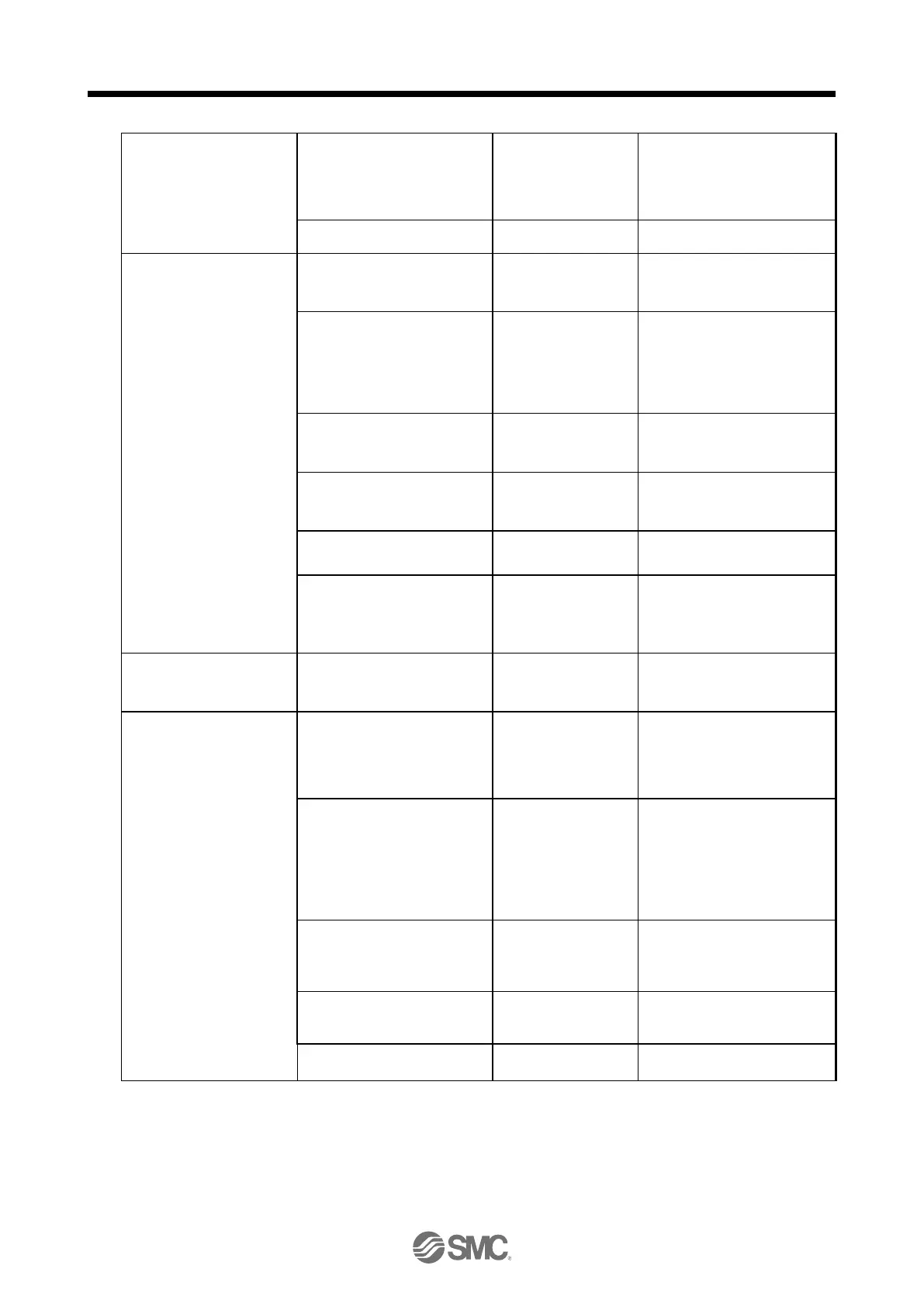

8. TROUBLESHOOTING

8 - 76

A load for the shaft of the servo

motor is large.

Check the load for the

shaft of the servo motor.

Adjust the load for the shaft to

within specifications of the servo

motor.

For the shaft permissible load,

refer to "Servo Motor Instruction

Manual (Vol. 3)".

An external vibration propagated to

the servo motor.

Check the vibration

from outside.

Prevent the vibration from the

external vibration source.

The rotation accuracy is low.

(The speed is unstable.)

The servo gain is low. Or the

response of auto tuning is low.

Check if the trouble is

solved by increasing auto

tuning response ([Pr.

PA09]).

The torque is insufficient due to

large load.

Check instantaneous

torque using status

display or setup software

(MR Configurator2

TM

) if

the load exceeds the

maximum torque or

torque limit value.

Reduce the load or use a larger

capacity servo motor.

An unintended torque limit has

been enabled.

Check if TLC (Limiting

torque) is on using status

display or setup software

(MR Configurator2

TM

).

The setting of the torque limit is

incorrect.

Check if the limiting

torque is too low.

[Pr. PA11] and [Pr.

PA12], or analog input

For a servo motor with an

electromagnetic brake, the lock

has not released.

Check the power supply

of the electromagnetic

brake.

Turn on the electromagnetic brake

power.

The command from the controller

is unstable.

Check the ripple of the

command

frequency with setup

software (MR

Configurator2

TM

).

Review the command from the

controller. Check the cable for

command if there is failure such

as disconnection.

The machine vibrates

unsteadily when it stops.

The servo gain is low. Or the

response of auto tuning is low.

Check if the trouble is

solved by increasing

auto tuning response

([Pr. PA09]).

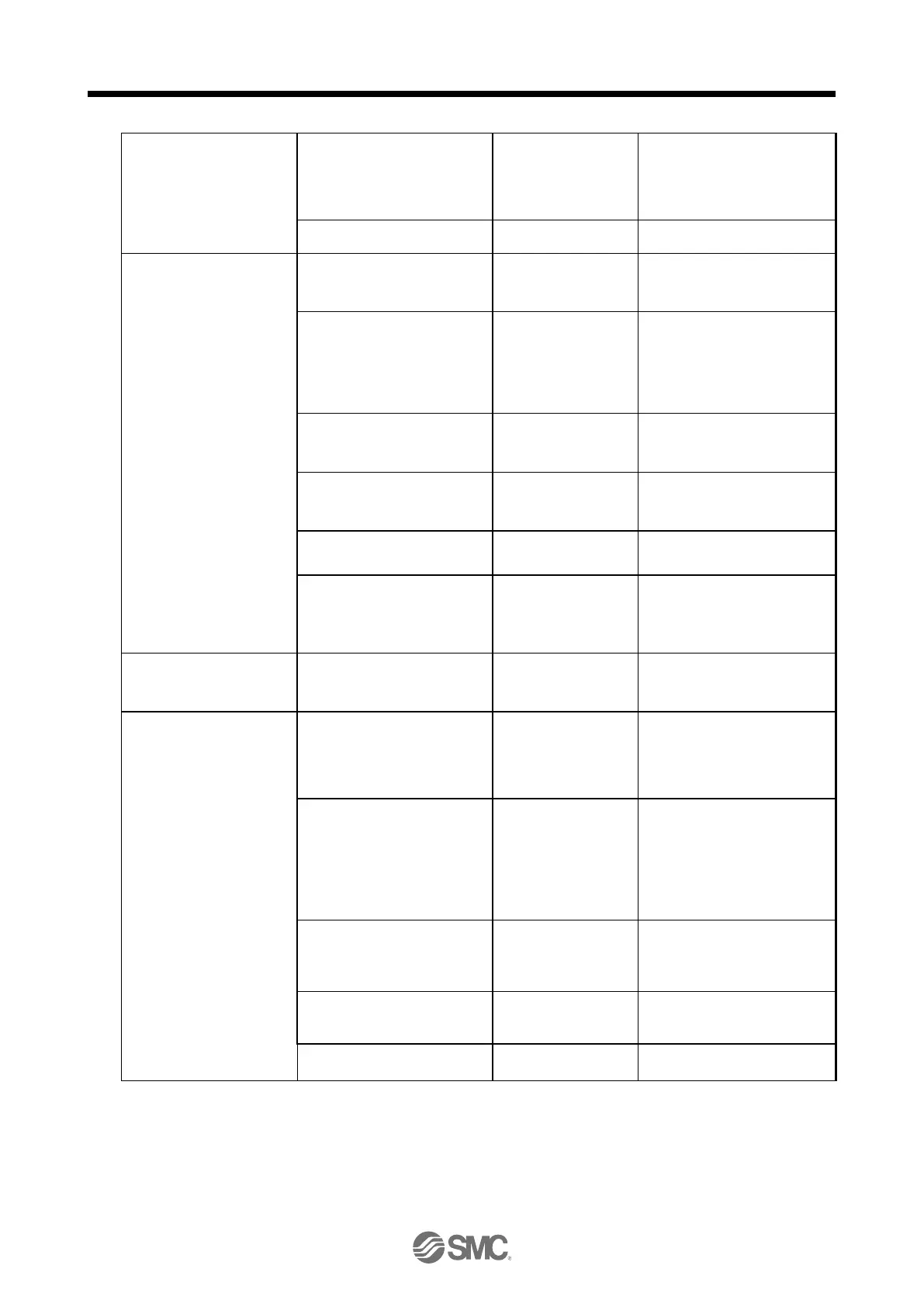

The servo motor starts to drive

immediately after power on of

the driver.The servo motor

starts to drive immediately

after servo-on.

SON (Servo-on) is on at power

on.

Check if SON (Servo-

on) and RD (Ready) are

on using status display

or setup software (MR

Configurator2

TM

).

Review the sequence of

SON(Servo-on).

An analog signal is inputted from

the beginning.

Check the status of

analog speed command

and analog torque

command using status

display or setup

software (MR

Configurator2

TM

).

Review the timing of inputting

analog signal.

Zero point of an analog signal

deviates.

Check if the servo motor

drives while 0 V is

inputted to the analog

signal.

Execute the VC automatic offset

or adjust offset of the analog

signal with

[

Pr.PC37

]

or

[

Pr.PC38

]

.

For a servo motor with an

electromagnetic brake, the lock

release timing is not correct.

Check the lock release

timing.

Review the lock releae timing.

The connection of the servo

motor is incorrect.

Check the wiring of

U/V/W.

Loading...

Loading...