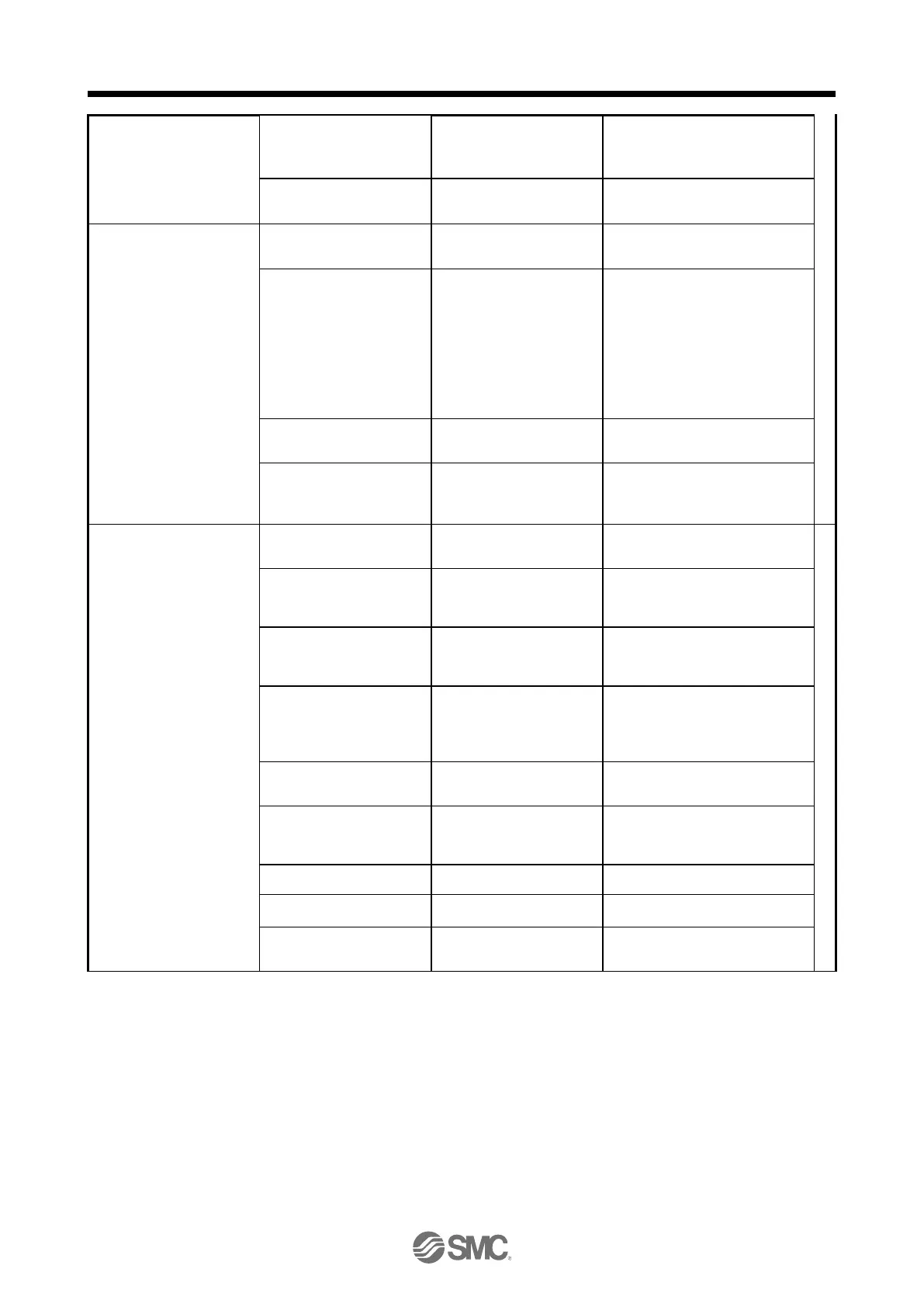

8. TROUBLESHOOTING

8 - 75

acceleration/deceleration is

overshooting exceeding the

limit of the servo motor when

the motor stops.

during

acceleration/deceleration if

torque/thrust exceeds the

maximum torque/thrust.

increasing acceleration/

deceleration time and reducing

load.

The servo gain is low. Or the

response of auto tuning is

low.

Check if the trouble is solved

by increasing auto tuning

response ([Pr. PA09]).

An unusual noise is occurring

atthe servo motor.

The servo gain is low. Or the

response of auto tuning is

low.

Check if the trouble is solved

by increasing auto tuning

response ([Pr. PA09]).

If the servo motor may be

driven with safety, remove the

load and check the noise with

the servo motor only.

If you can remove the servo

motor from machine, remove

the servo motor power cable

to release the lock and check

the noise by rotating the shaft

by your hands.

Noising means that the bearing

life expired. Replace the servo

motor. When not noising, maintain

the machine.

For a servo motor with an

electromagnetic brake, the

lock has not released.

Check the power supply of the

electromagnetic brake.

Turn on the electromagnetic brake

power.

For a servo motor with an

electromagnetic brake, the

lock release timing is not

correct.

Check the lock release

timing.

Review the lock release timing.

Please consider that the

electromagnetic brake has

release delay time.

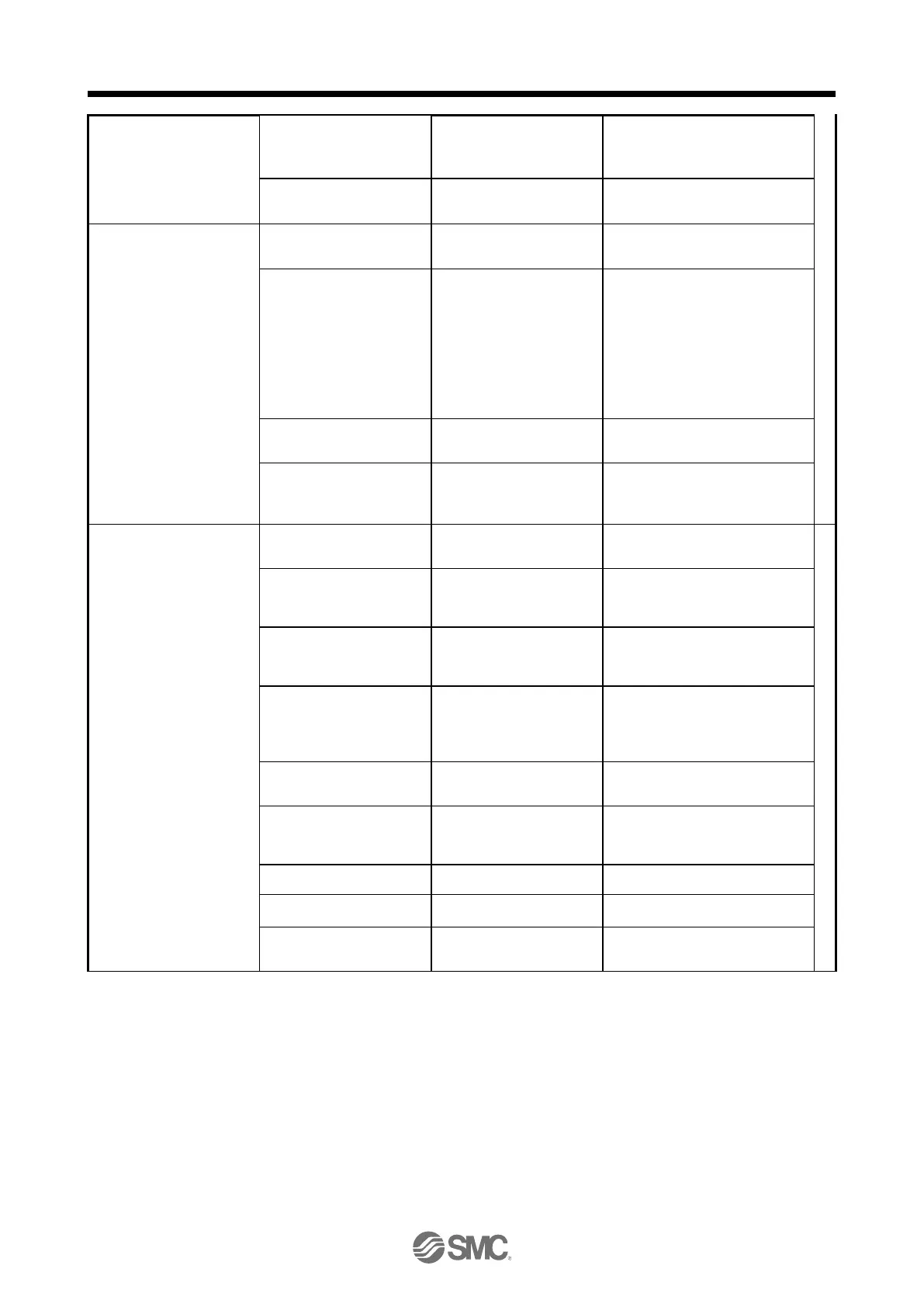

The servo motor vibrates.

The servo gain is too high. Or

the response of auto tuning is

too high.

Check if the trouble is solved

by reducing auto tuning

response ([Pr. PA09]).

The machine is vibrating

(resonating).

If the servo motor may be

driven with safety, check if the

trouble is solved by one-touch

tuning or adaptive tuning.

Adjust the machine resonance

suppression filter.

The load side is vibrating.

If the servo motor may be

driven with safety, check if the

trouble is solved by advanced

vibration suppression control.

Execute the advanced vibration

suppression control .

Feedback pulses are being

miscounted due to entered

noise into an encoder cable.

Check the cumulative

feedback pulses using status

display or setup software (MR

Configurator2

TM

) if its

numerical value is skipped.

Please take countermeasures

against noise by laying the

encoder cable apart from power

cables, etc.

There is a backlash between

the servo motor and machine

(such as gear, coupling).

Check if there is a backlash on

the machine.

Adjust the backlash on the

coupling and machine.

The rigidity of the servo motor

mounting part is low.

Check the mounting part of

the servo motor.

Increase the rigidity of the

mounting part by such as

increasing the board thickness

and by reinforcing the part with ribs.

The connection of the servo

motor is incorrect.

Check the wiring of U/V/W.

An unbalanced torque of the

machine is large.

Check if the vibration varies

depending on the speed.

Adjust balance of the machine.

The eccentricity due to core

gap is large.

Check the mounting accuracy

of the servo motor and

machine.

Loading...

Loading...