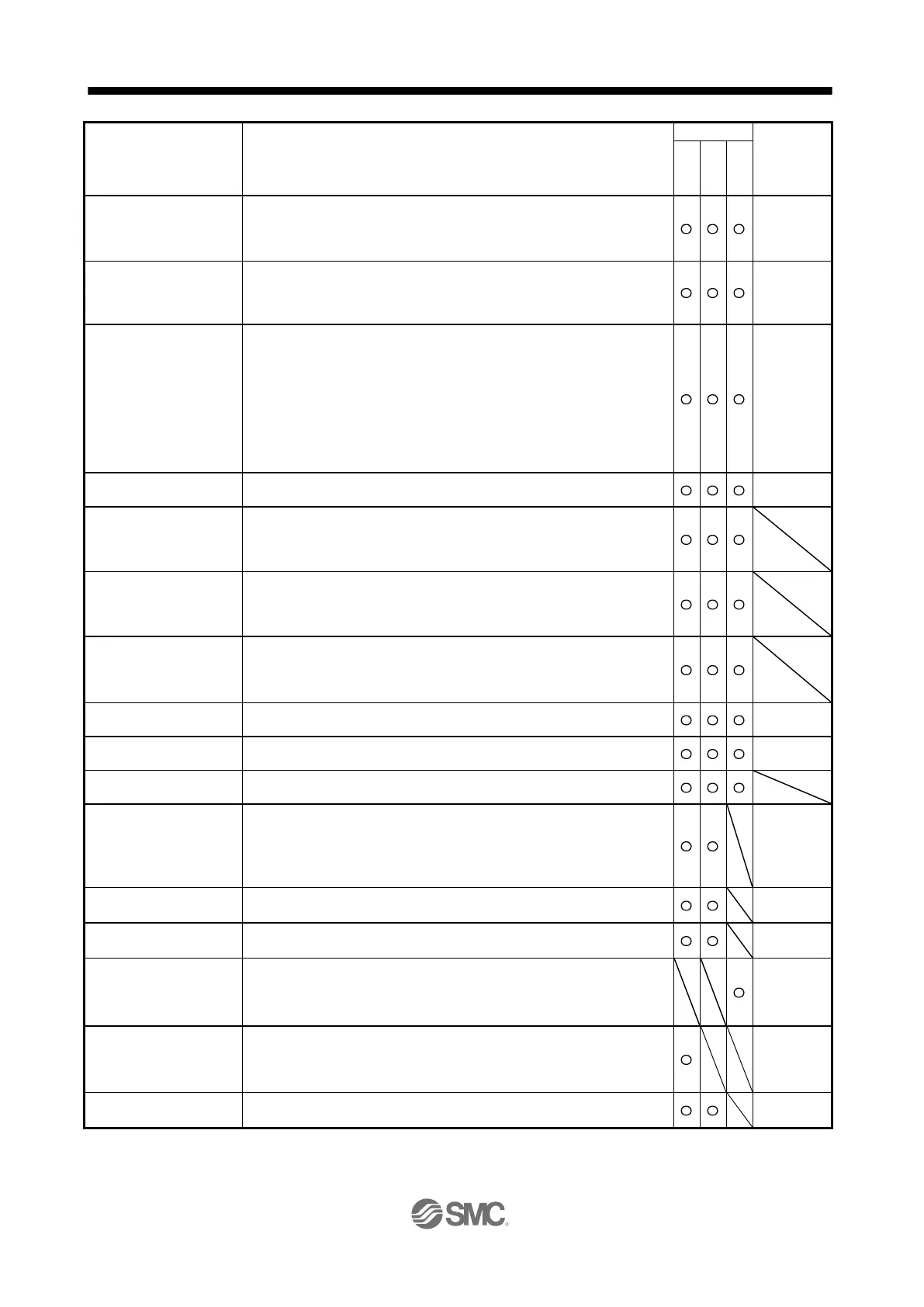

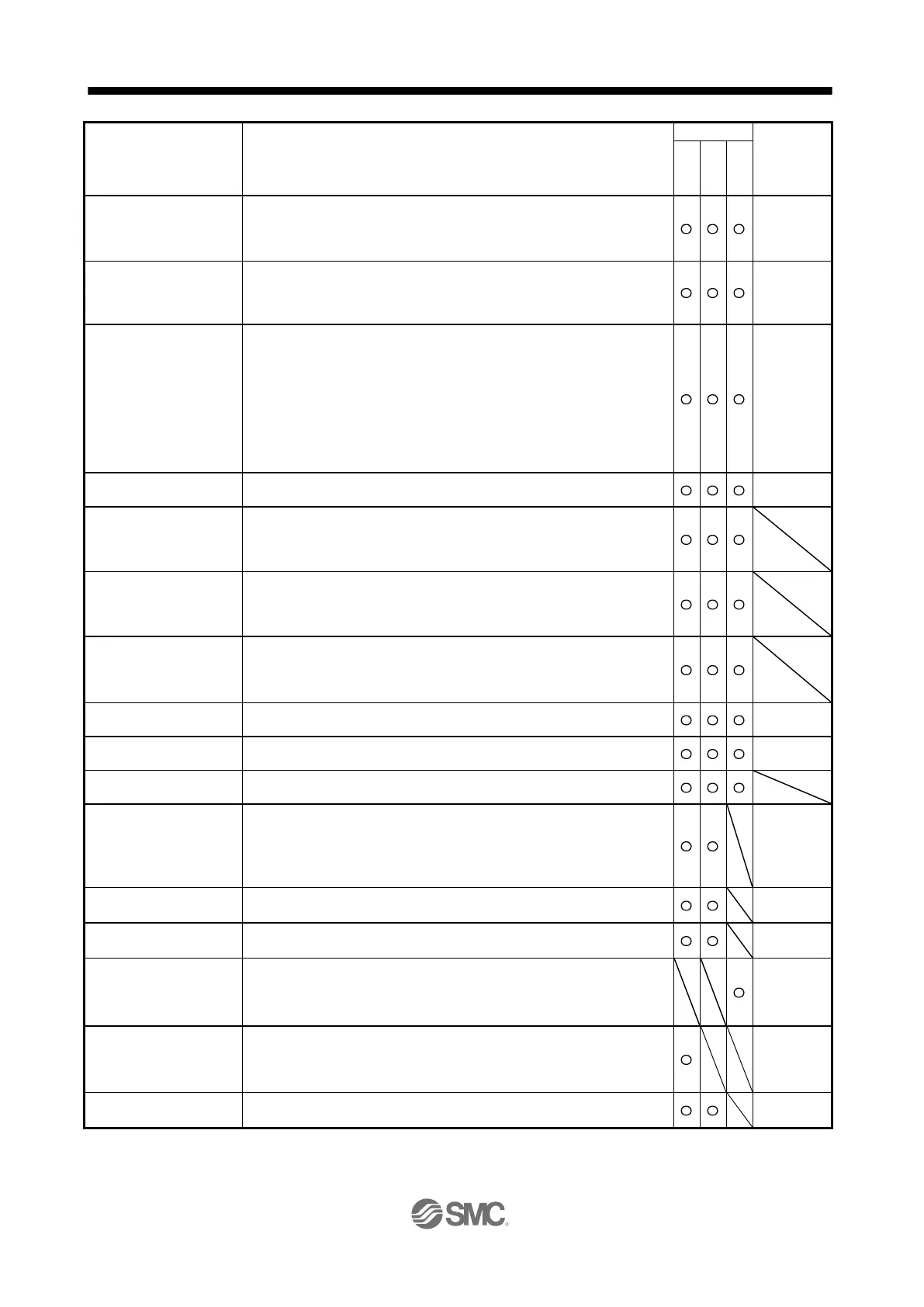

This function which complies with the SEMI-F47 standard enables to avoid

triggering [AL. 10 Undervoltage] using the electrical energy charged in the

capacitor in case that an instantaneous power failure occurs during

operation.

_ section

7.4

[Pr. PA20]

[Pr. PF25]

This function makes the equipment continue operating even under the

condition that an alarm occurs.

The tough drive function includes two types: the vibration tough drive and

the instantaneous power failure tough drive.

This function continuously monitors the servo status and records the status

transition before and after an alarm for a fixed period of time. You can check

the recorded data on the drive recorder window on setup software (MR

Configurator2

TM

) by clicking the "Graph" button.

However, the drive recorder will not operate on the following conditions.

1. You are using the graph function of setup software (MR

Configurator2

TM

).

2. You are using the machine analyzer function.

3. [Pr. PF21] is set to "-1".

This driver complies with the STO function as functional safety of IEC/EN

61800-5-2. You can create a safety system for the equipment easily.

Driver life diagnosis

function

You can check the cumulative energization time and the number of on/off

times of the inrush relay. This function gives an indication of the replacement

time for parts of the Driver including a capacitor and a relay before they

malfunction.

Power monitoring function

This function calculates the power running energy and the regenerative

power from the data in the driver such as speed and current. Power

consumption and others are displayed on setup software (MR

Configurator2

TM

).

Machine diagnosis

function

From the data in the driver, this function estimates the friction and vibrational

component of the drive system in the equipment and recognizes an error in

the machine parts, including a ball screw and bearing.

setup software (MR Configurator2

TM

) is necessary for this function.

Lost motion compensation

function

This function improves the response delay occurred when the machine

moving direction is reversed.

This function sets constant and uniform acceleration/deceleration droop

pulses to almost 0.

Limits travel intervals using LSP (Forward rotation stroke end) and LSN

(Reverse rotation stroke end).

S-pattern

acceleration/deceleration

Enables smooth acceleration and deceleration.

Set S-pattern acceleration/deceleration time constants with [Pr. PC03].

Compared with linear acceleration/deceleration, the

acceleration/deceleration time will be longer for the S-pattern

acceleration/deceleration time constants regardless of command speed.

Limits travel intervals by address using parameters.

Enables the same function with the limit switch by setting parameters.

Limits a servo motor speed with analog inputs.

A value can be changed from 0% to 200% for a set speed.

A commanded speed multiplied by an override value selected with OVR

(Override selection) will be an actual servo motor speed.

A value can be changed from 0% to 360% for a set speed.

[Pr. PT42]

[Pr. PT43]

section

6.4.4 (2)

After an operation travels to a target position with a JOG operation or

manual pulse generator operation, pushing the SET button of the operation

part or turning on TCH (Teach) will import position data.

Section

3.1.10

Section

3.2.10

High-resolution analog

input (VC)

The analog input resolution can be increased to 16 bits.

Loading...

Loading...