Use a noise filter to reduce the effects of electromagnetic interference. Electromagnetic interference may

occur on electronic devices used near the driver.

Do not burn or disassemble the driver, as toxic gas may be generated.

Use a noise filter, etc. to minimize the influence of electromagnetic interference. Electromagnetic

interference may be given to the electronic equipment used near the driver.

Burning or breaking a driver may cause a toxic gas. Do not burn or break it.

Use the driver with the specified servo motor.

The lock on the servo motor is designed to hold the motor shaft and should not be used for ordinary

braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor

are coupled via a timing belt), the lock may not hold the motor shaft. To ensure safety, install a stopper

on the machine side.

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with a lock or external lock to prevent the condition.

Do not use the 24 V DC interface power supply for the lock.

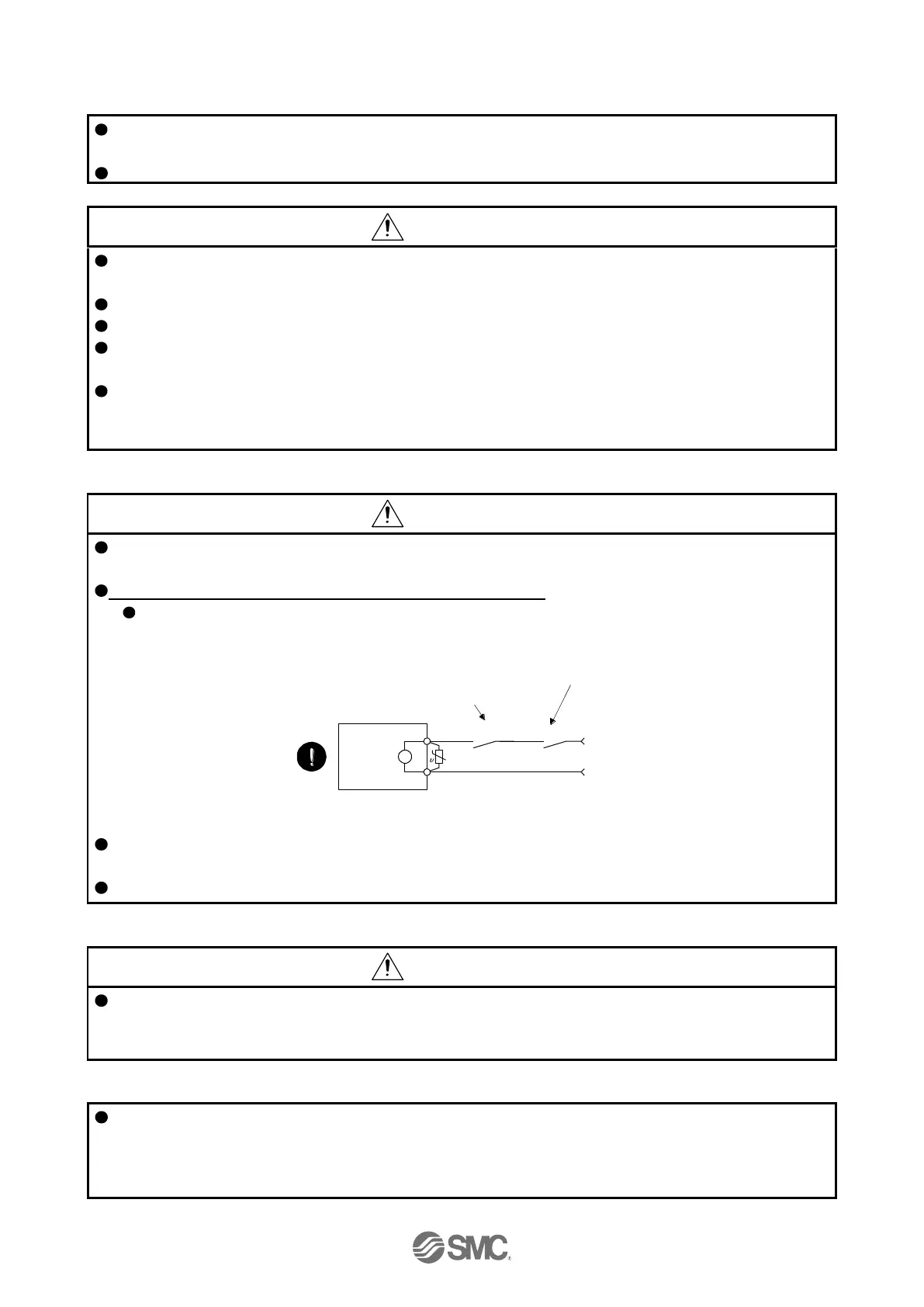

Configure a lock circuit so that it is activated also by an external EMG stop switch.

Servo motor

Electromagnetic brake

B

RA

Contacts must be opened

with the EMG stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

24 V DC

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

(6) Maintenance, inspection and parts replacement

With age, the electrolytic capacitor of the driver will deteriorate. To prevent a secondary accident due to a

malfunction, it is recommend that the electrolytic capacitor be replaced every 10 years when it is used in

general environment. Please contact your local sales office.

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Specifications and

Instruction Manual.

Contacts must be opened when ALM

(Malfunction) and MBR (Electromagnetic

brake interlock) turns off.

Refer to section 3.10.3 when wiring for the circuit configuration.

Loading...

Loading...