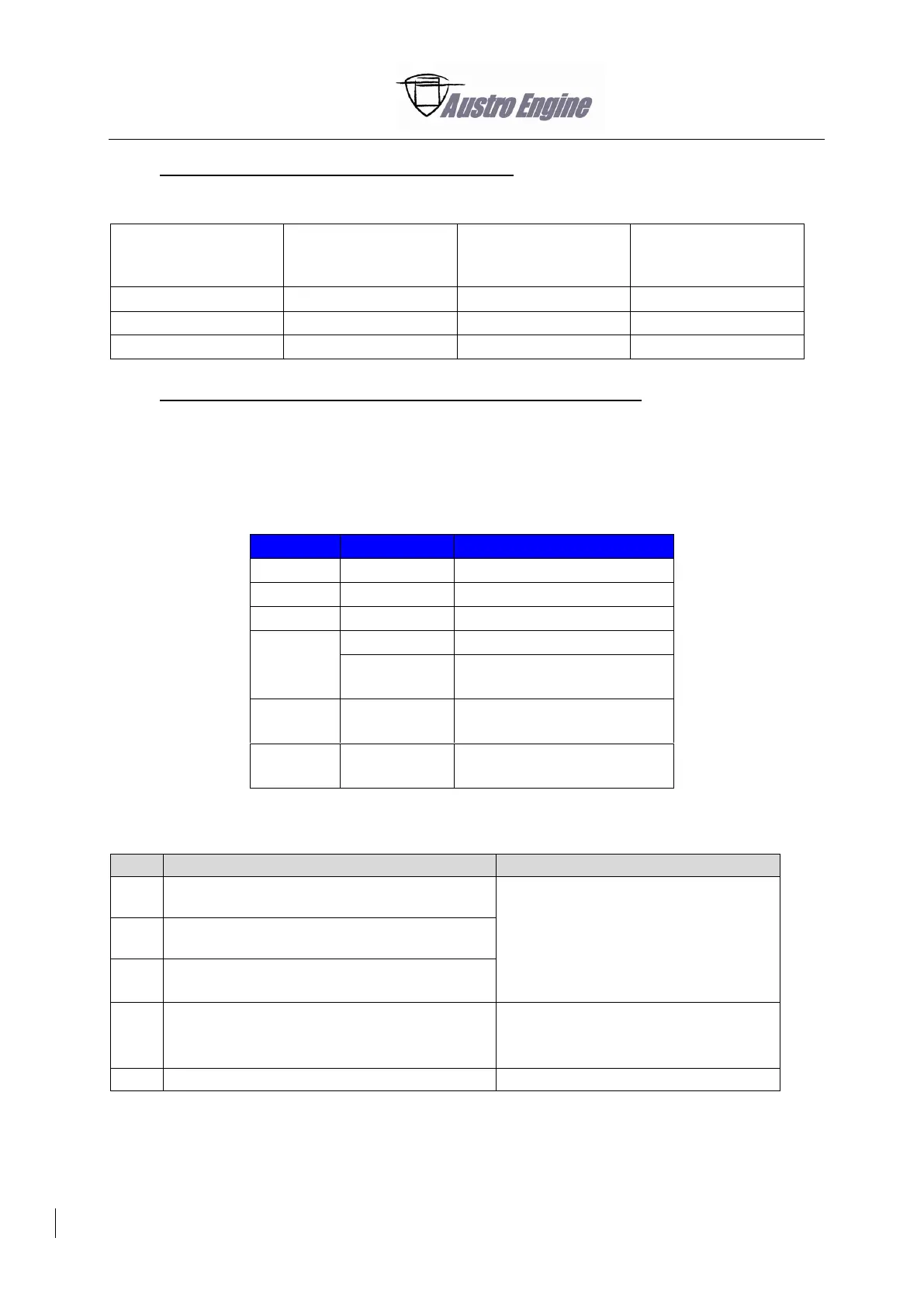

3. Acceptance criteria for alternator bench tests

For alternator tests on an alternator test bench, the following acceptance criteria apply:

Hold time of load

Currents [s]

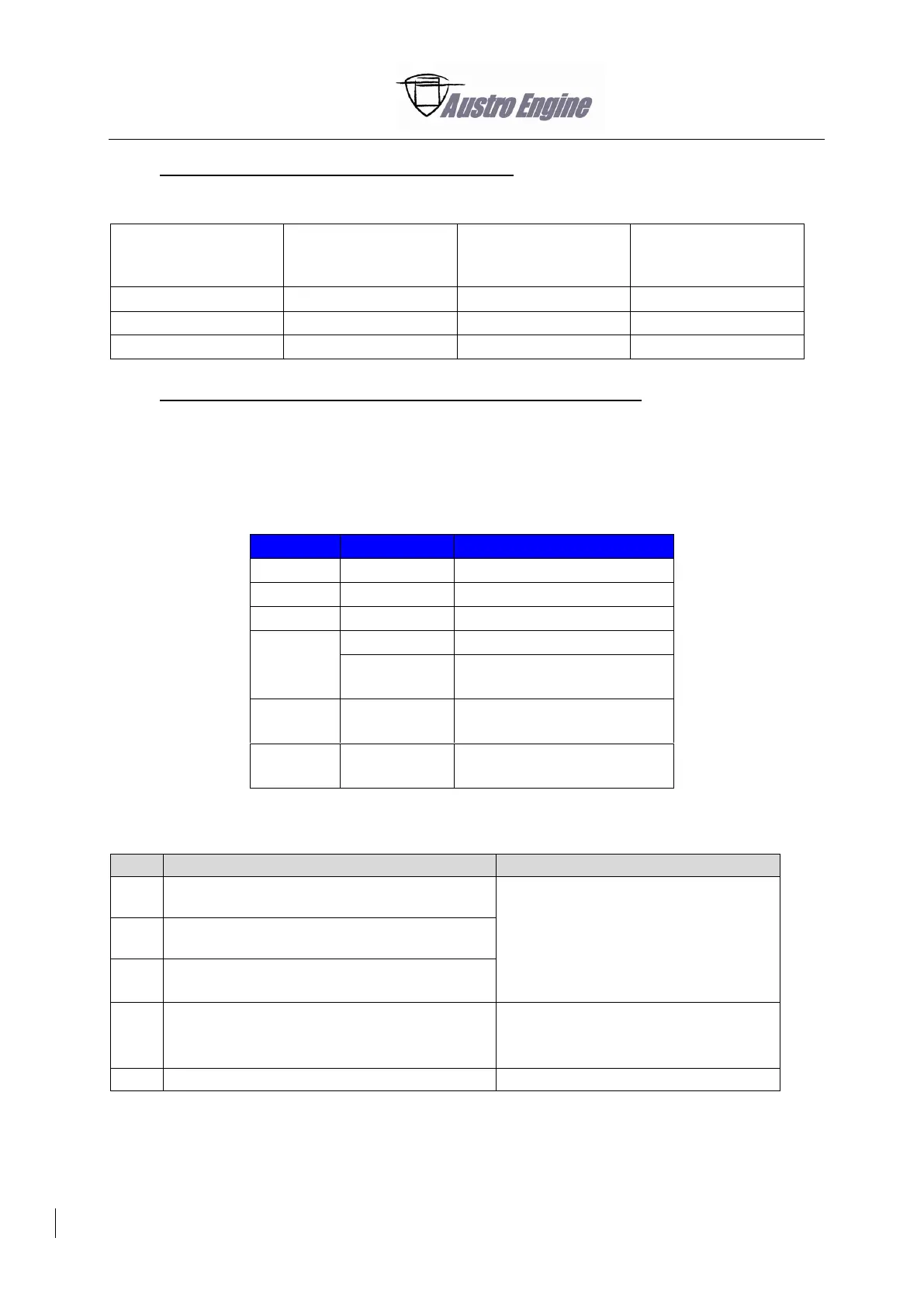

4. Inspection of Alternator E4A-91-400-000 and Carbon Brushes

This section lists the steps to disassemble the alternator and its components (e.g. brush holder) and

to measure the length of the carbon brushes.

This section contains also the criteria for replacing the Brush Holder assembly E4A-91-410-000.

A. Special Tools

Slotted Screw Driver (~2mm)

B. Remove the Brush the Holder Assembly

Remove all black covers of the terminals

B+/W/L.

Refer to Fig. 24 - 33 and Fig. 24 - 34.

Use Torx T20 or with wrench

(hexagonal) size 7, depending on the

screwing.

Remove the two screws/hexagon nuts G and

G2.

Remove the plastic cover on the backside of

the alternator.

Remove the hexagon nut T2

(R1 screw/washer + spacer).

Use wrench Torx T20, and Terminal

Screw T2.

Carefully remove Brush Holder Assembly.

Loading...

Loading...