76 - Maintenance Procedures

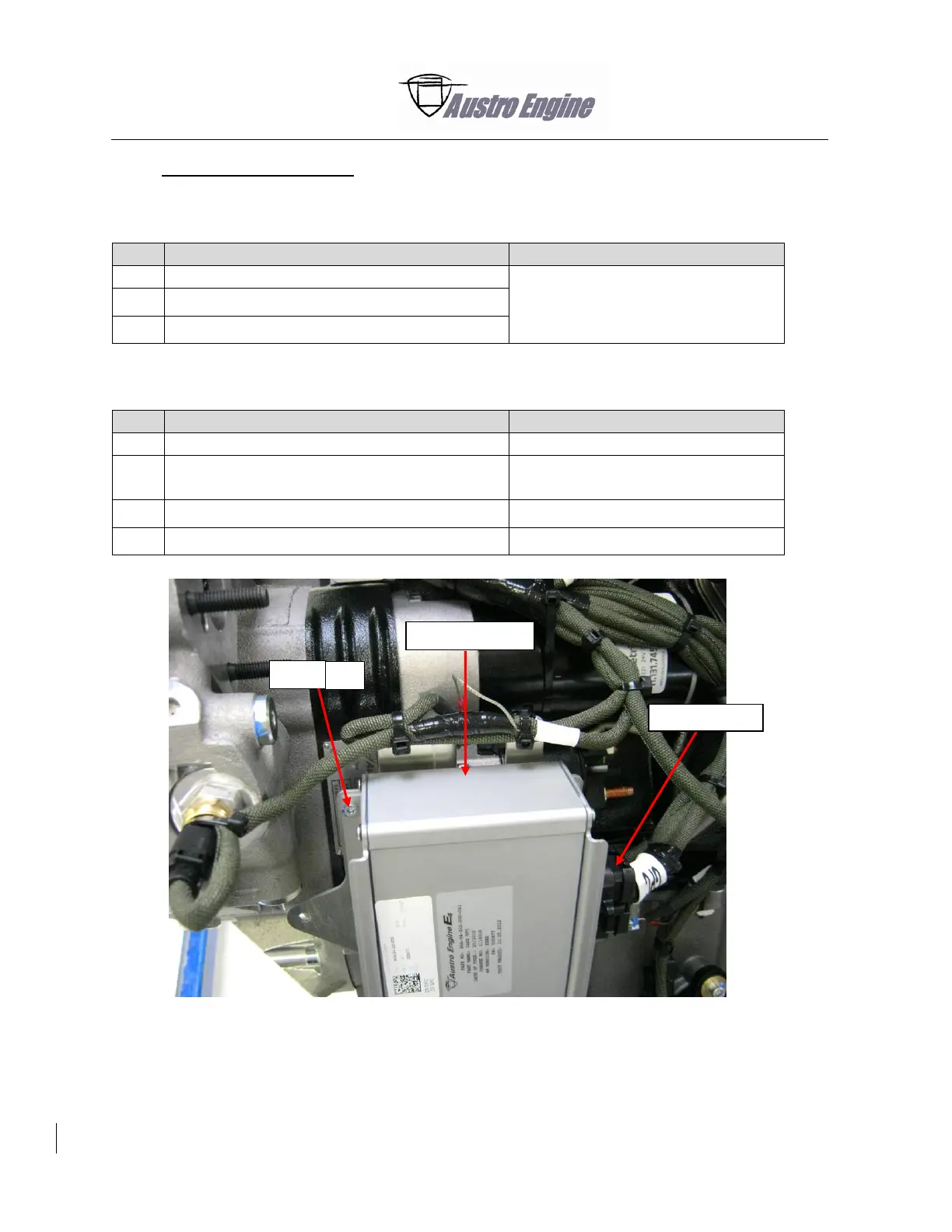

3. Glow Plug Control (GPC)

A. Remove the Glow Plug Control

Remove the GPC connector.

Remove the four screws from the GPC.

B. Install the Glow Plug Control

Tighten the nuts on the GPC.

Connect the GPC connector.

Refer to Section 71-00-01.

Fig. 76 - 10 Glow Plug Control

Loading...

Loading...