1126800 SmartPAC 2 with WPC Integration

Page 78 Chapter 2 Installing SmartPAC 2 and WPC

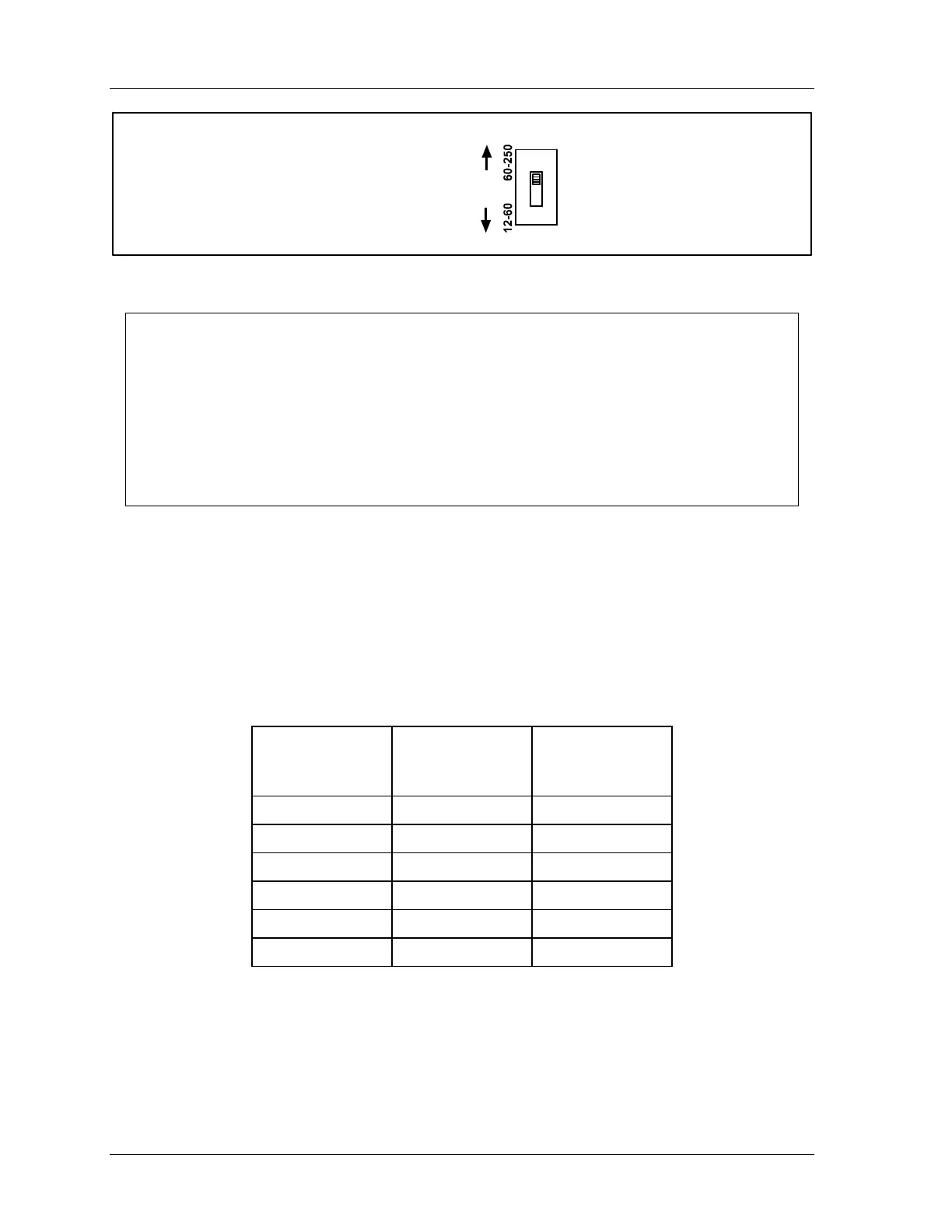

S101

Push switch down

for 12-60V

Push switch up

for 60-250V

Figure 2 - 21. Input check switch (S101)

NOTICE

HOW THE INPUT CHECK CIRCUIT DETECTS RESOLVER CHAIN BREAKAGE

When the dual safety valve relay is energized by the press control to start the press, voltage

will be produced in the input check circuit. This signals SmartPAC 2 that the press ram

should begin to move. If SmartPAC 2 gets no signals from the resolver within the start time

limit (resolver not turning), it opens the emergency stop circuit. A “loss of rotation” fault

message is displayed on the screen. The press could have started but the resolver belt or

chain broke or was significantly too loose so that the resolver shaft did not move. Other

possible reasons for the fault could be low air pressure to the clutch or a bad clutch.

2. Run the stop circuit, and input check circuit wires to SmartPAC 2 through flexible

liquid-tight conduit to the enclosure. Because SmartPAC 2 is rated NEMA 12 (protected

against dust and oil), you must use conduit of the same rating and make proper

connections to ensure NEMA 12 protection with the enclosure.

3. Locate connector TB102 for the stop circuits. It should be plugged into the socket.

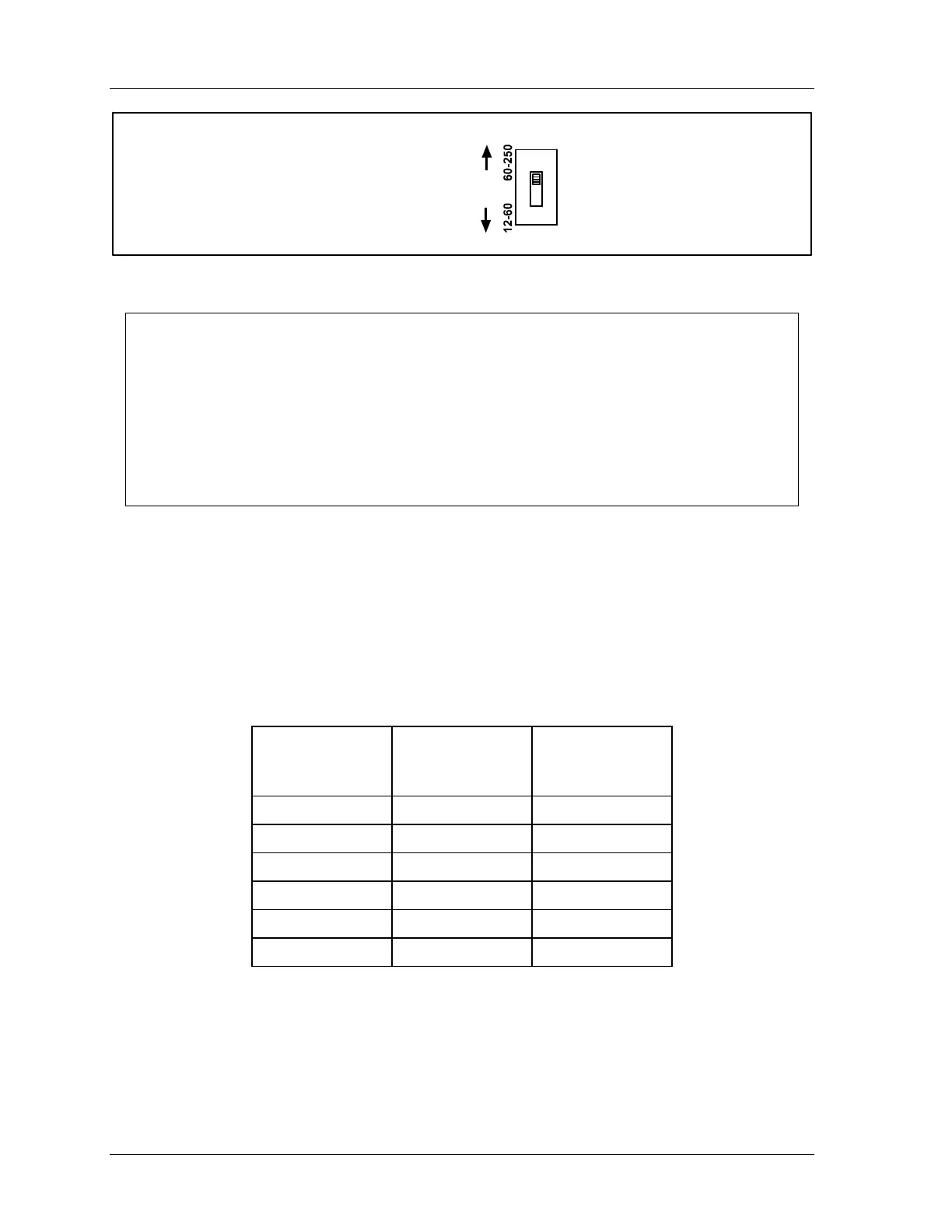

Connect the wires for the stop circuits and input check SmartPAC 2 as shown in the table

below. (Also refer to Figure 1 at the end of the manual.)

Table 2 - 4. Wiring to Input Check and Stop Circuits

SmartPAC 2

TB102

Terminal

Wiring

Designation

WPC Control

Board

Pin #

205 A 41

206 B 29

207 E-Stop 68

208 E-Stop 67

209 Top Stop 80

210 Top Stop 79

9. Plug the connector back into its slot. Double check connections with markings at the

connector base to make sure that you did not wire it backwards.

10. Connect top stop, E-stop, and check input circuit wires at the press control.

Loading...

Loading...