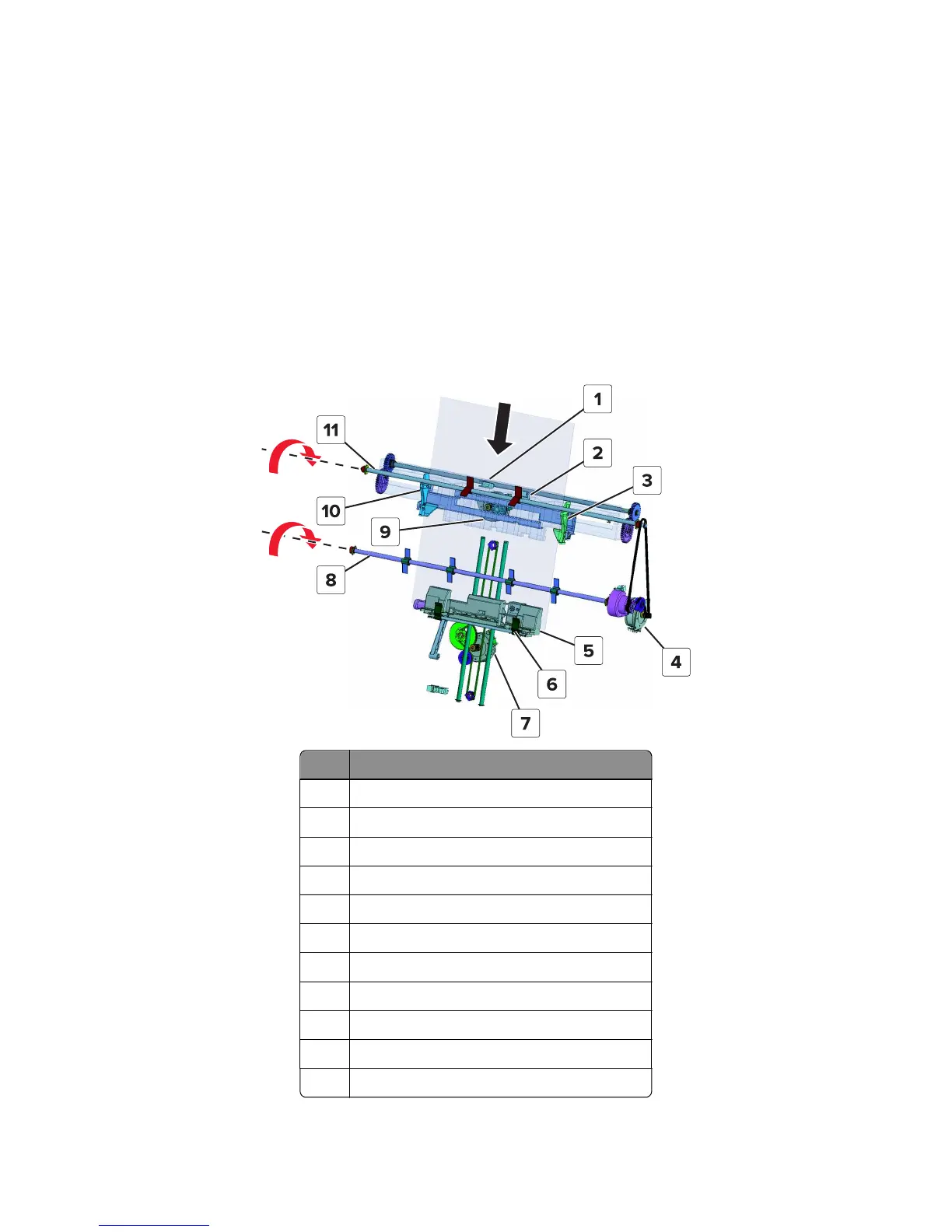

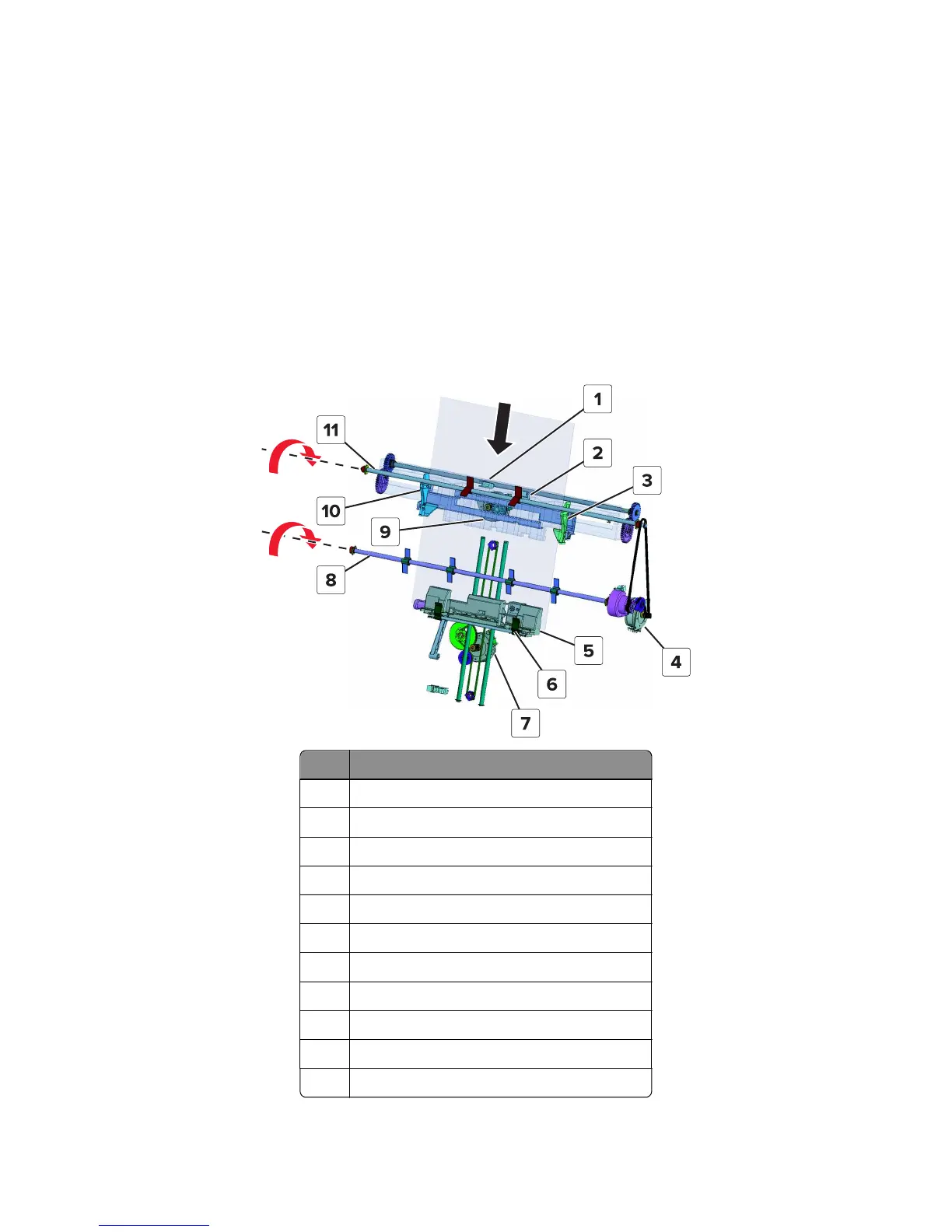

Booklet maker compiler section paper feed and alignment

When the sensor (SHPF booklet gate) detects the leading edge of the paper, the motor (booklet maker tamper) moves

the tampers to a width that is slightly wider than the paper. The motor (booklet maker aligner) moves the aligner to a

preset position depending on the paper length.

The motor (booklet maker paddle) rotates the upper and lower paddles. The paddles push down the paper to align the

short edge on the aligner. After the trailing edge of the paper passes the sensor (booklet maker transport), the tampers

move back and forth to align the long edge of the paper.

The paddles stop rotating after the trailing edge of the paper passes the sensor (SHPF booklet gate). The tampers return

to the home position after the alignment is completed. Succeeding sheets are individually fed and are aligned in the

same manner.

After all of the sheets are aligned, the aligner solenoid retracts the stack clamp to hold the paper stack in place for

folding. The aligner moves to a preset position depending on the number of folds needed.

# Part

1 Sensor (booklet maker tamper paper present)

2 Sensor (booklet maker tamper home)

3 Front tamper plate

4 Motor (booklet maker paddle)

5 Aligner

6 Stack clamp

7 Motor (booklet maker aligner)

8 Lower paddle

9 Motor (booklet maker tamper)

10 Rear tamper plate

11 Upper paddle

4021, 7421

Appendix C: Theory of operation

671

Loading...

Loading...