The more ROPs, EPHs or transitions included in the recipe, the longer the time needed to

process the recipe. To allow the configuration engineer of the process cell to set the optimum

allocation of time for running the process (actuators, sensors, process logic etc.) and time for

processing recipes, there are two parameters in UNIT_PLC:

● Max_CycleRun IN

Maximum time per processing cycle that may be used to process batch control The default

value is 25 ms and the input of the block is not visibly interconnected.

● QAvgRecProcTime INOUT

Average time per processing cycle that is currently used to process batch control. Two

measured values, the average calculated time of the last cycle + measured value of the

current cycle are taken into account for each calculation.

Examples are provided below to show the two parameters. This assumes that only one unit is

fitted in the AS.

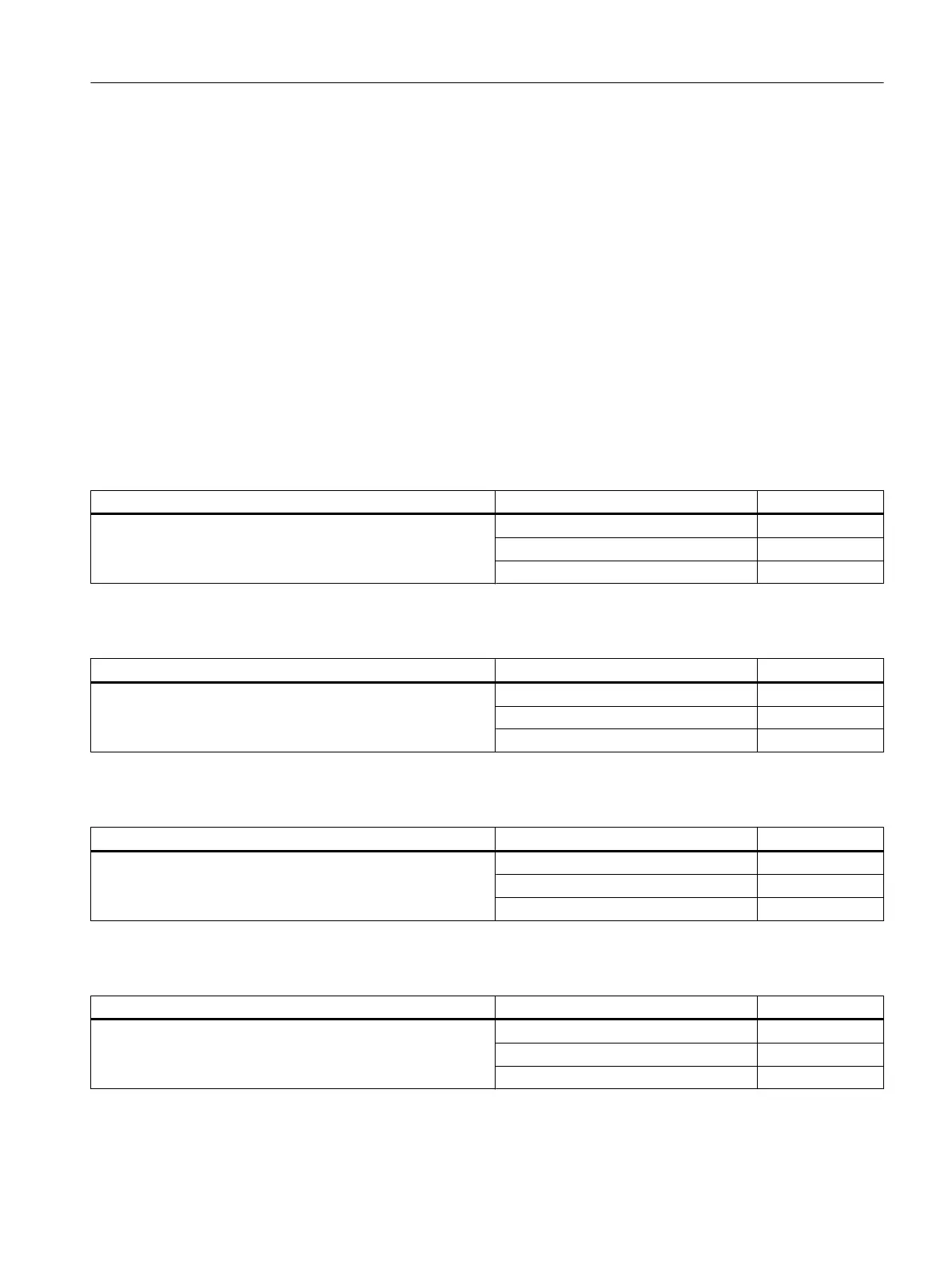

Example 1: UNIT_PLC installed in OB32 (1000 ms watchdog interrupt), suitable parameter assignment

MaxCyclRun is set to 50 ms Assessment

approx. 1/20 processing time for batch processing

approx. 19/20 processing time for processing processes in the

OB 32 and other OBs

QAvgRecProTime = 30 to 40 ms OK

QAvgRecProTime = 40 to 50 ms Still OK

QAvgRecProTime = 50 to 60 ms* Not OK

Example 2: UNIT_PLC installed in OB32 (1000 ms watchdog interrupt), suitable parameter assignment

MaxCyclRun parameterized at 100 ms Assessment

approx. 1/10 processing time for batch processing

approx. 9/10 processing time for processing processes in the

OB 32 and other OBs

QAvgRecProTime = 80 to 90 ms OK

QAvgRecProTime = 90 to 100 ms Still OK

QAvgRecProTime = 100 to 110 ms* Not OK

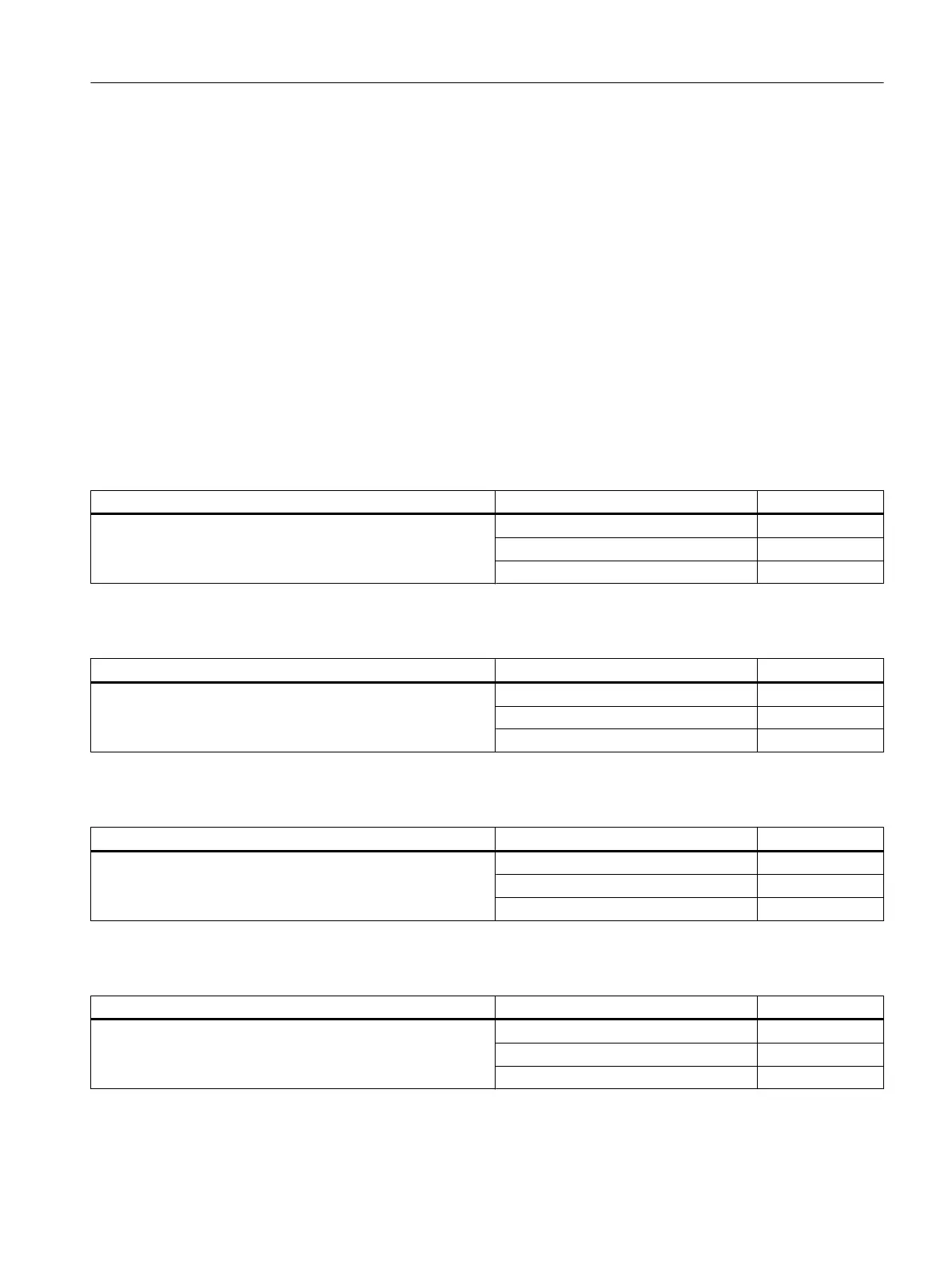

Example 3: UNIT_PLC installed in OB35 (100 ms watchdog interrupt), acceptable parameter assignment

MaxCyclRun parameterized at 30 ms Assessment

approx. 1/3 processing time for batch processing

approx. 2/3 processing time for processing processes in the

OB 35 and other OBs

QAvgRecProTime = 10 to 20 ms OK

QAvgRecProTime = 20 to 30 ms Still OK

QAvgRecProTime = 30 to 40 ms* Not OK

Example 4: UNIT_PLC installed in OB35 (100 ms watchdog interrupt), bad parameter assignment

MaxCyclRun is set to 50 ms Assessment

approx. 1/2 processing time for batch processing

approx. 1/2 processing time for processing processes in the

OB 35 and other OBs

QAvgRecProTime = 30 to 40 ms OK

QAvgRecProTime = 40 to 50 ms Still OK

QAvgRecProTime = 50 to 60 ms* Not OK

* Recipe processing cannot be undertaken in a processing cycle but must instead be split

over two processing cycles. The system thereby extends the batch runtime by one processing

Engineering

7.1 Basic engineering for PCS 7

SIMATIC BATCH V8.2

Operating Manual, 02/2016, A5E35958174-AA 147

Loading...

Loading...