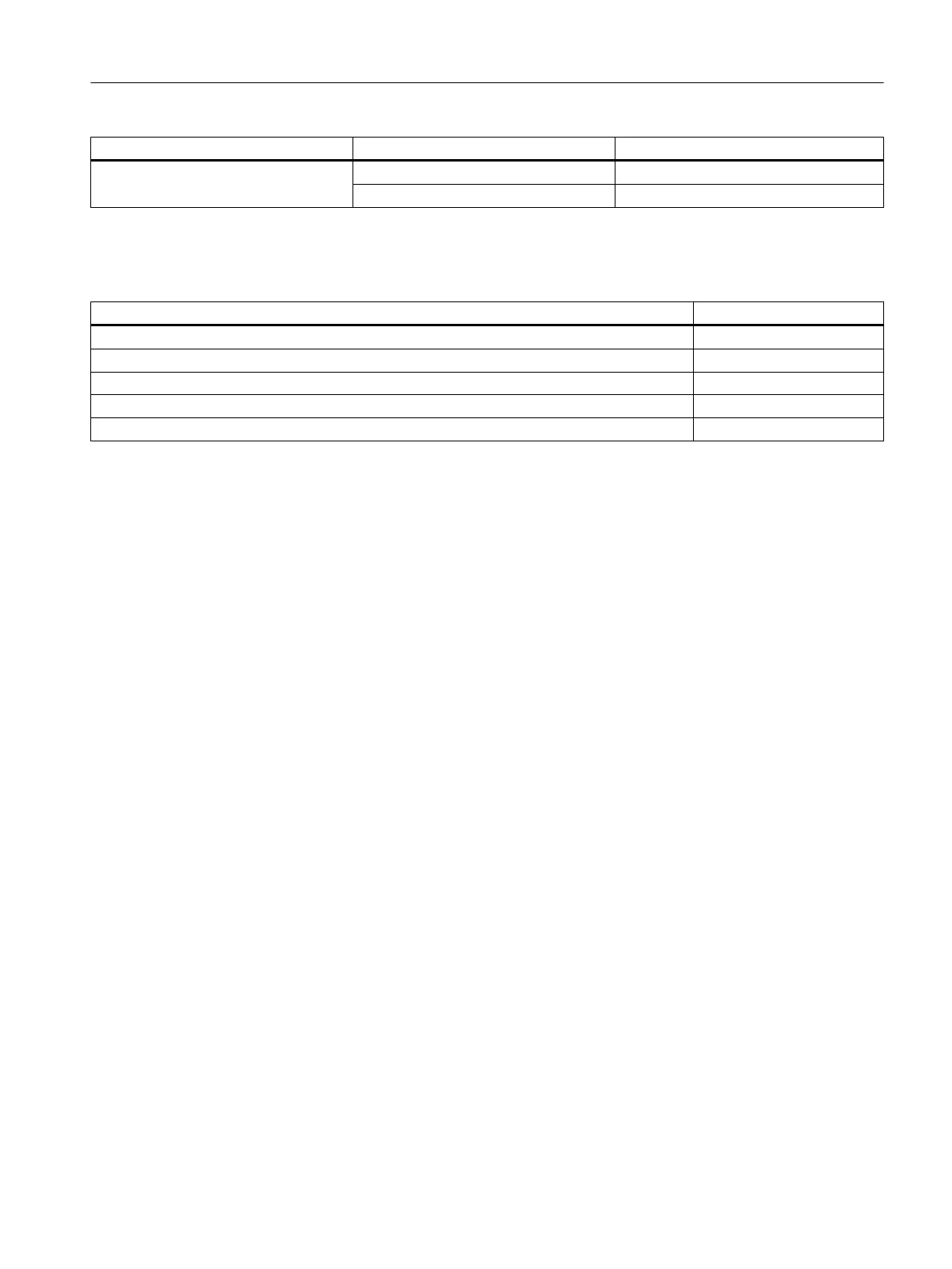

Memory allocations Description Memory required in KB

Dynamic part. Occupied by settings in

the BATCH configuration dialog.

per unit 57

per recipe unit procedure (RUP) 128

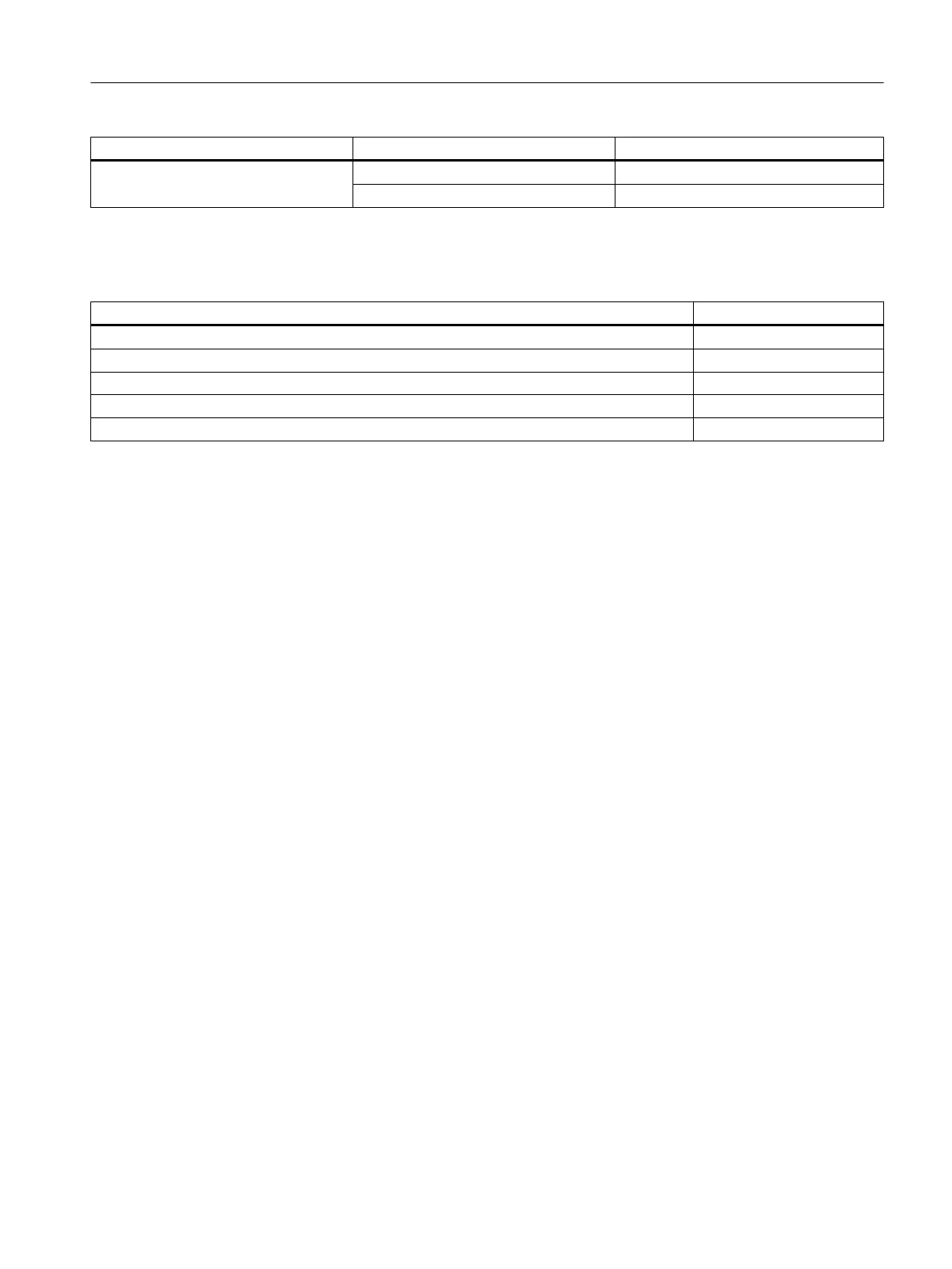

The following table shows the runtimes of the most important recipe structures that result from

the processing of a recipe unit procedure and are required to calculate a cycle time.

Recipe structure AS runtime

Completing recipe phase (average measured value) 1.8 ms

Updating setpoint (average measured value) 0.07 ms

Processing a transition (average measured value) 4 ms

Starting recipe phase (average measured value) 1.9 ms

Processing a recipe phase (average measured value) 2 ms

You can find an example of how to determine the memory requirements and the runtime in

the section "Measured results for calculating the performance of both operating modes

(Page 71)".

3.4.2 Concept expansion

Reason for expansion of the concept

Continuously increasing demands for higher product quality while simultaneously maintaining

full plant capacity have caused a variety of branches in the manufacturing industry to improve

and optimize their batch processes again and again.

For example, the food and beverage industry thus expect deterministic and above all fast step

change times from a batch control system because slow step changes can result in a reduction

in product output.

Requirements for fast batch processes

The determining logic of step changes is a basic requirement for both fast and parallel process

sequences, which need to be synchronized to specific steps. Fast process sequences, for

example, enable configuration of exact deceleration points for dosing, while precise parallel

sequences accelerate the material transfer to synchronization steps.

The following requirements must be met to obtain the needed fast batch processes:

● Clear reduction of the step change times to less than one second

● Clearly defined deterministics for the step change times for batch processing

Product introduction and installation

3.4 Operating modes in SIMATIC BATCH

SIMATIC BATCH V8.2

Operating Manual, 02/2016, A5E35958174-AA 43

Loading...

Loading...